Каталог Sumitomo пластины с алмазными вставками Sumidia - страница 41

Навигация

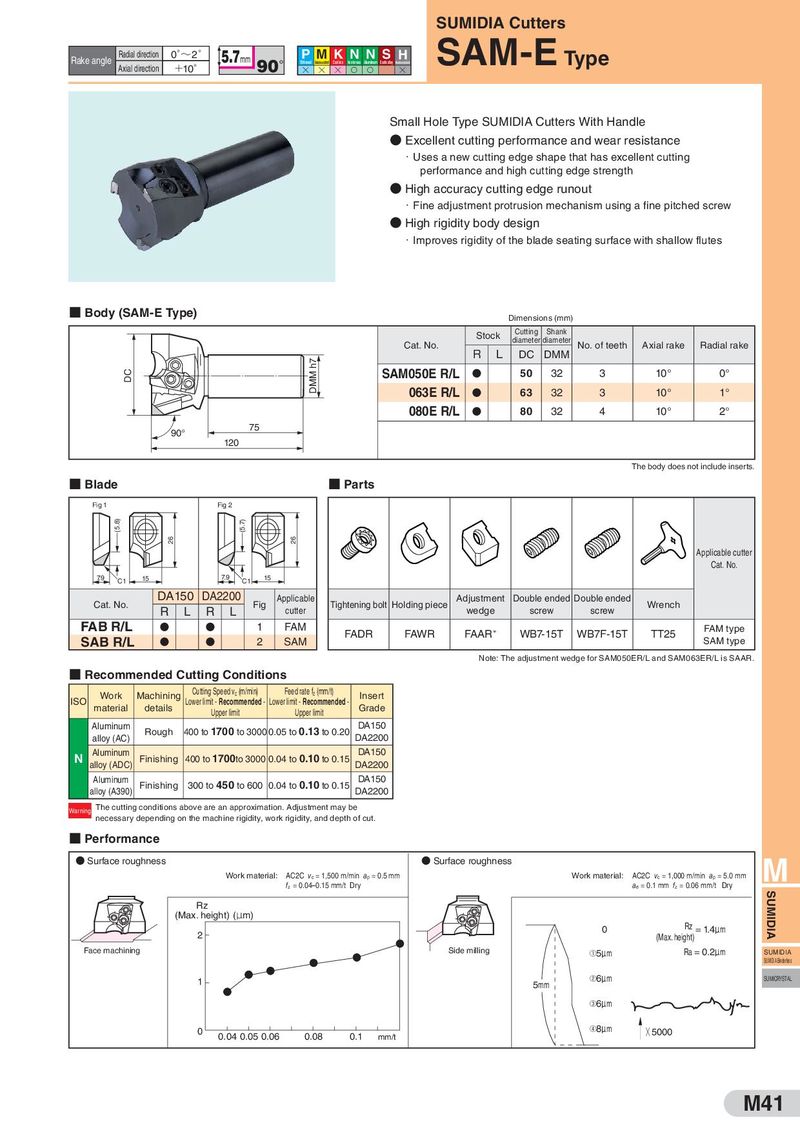

SUMIDIA Cutters Rake angle Radial direction 0°〜2° 5.7mm P M K N N S H SAM-E Type 90° Steel Stainless steel Cast iron Non-ferrous Aluminum Exotic alloy Hardened steel Axial direction +10° H H H S S H Small Hole Type SUMIDIA Cutters With Handle ● Excellent cutting performance and wear resistance ・Uses a new cutting edge shape that has excellent cutting performance and high cutting edge strength ● High accuracy cutting edge runout ・Fine adjustment protrusion mechanism using a fine pitched screw ● High rigidity body design ・Improves rigidity of the blade seating surface with shallow flutes ■ Body (SAM-E Type) Dimensions (mm) Stock Cutting Shank Cat. No. diameter diameter No. of teeth Axial rake Radial rake DMM h7 R L DC DMM DC SAM050E R/L D 50 32 3 10° 0° 063E R/L D 63 32 3 10° 1° 080E R/L D 80 32 4 10° 2° 90° 75 120 The body does not include inserts. ■ Blade ■ Parts Fig 1 Fig 2 (5.8) (5.7) 26 26 Applicable cutter Cat. No. 7.9 C1 15 7.9 C1 15 Cat. No. DA150 DA2200 Fig Applicable Tightening bolt Holding piece Adjustment Double ended Double ended Wrench R L R L cutter wedge screw screw FAB R/L D D 1 FAM FADR FAWR FAAR* WB7-15T WB7F-15T TT25 FAM type SAB R/L D D 2 SAM SAM type Note: The adjustment wedge for SAM050ER/L and SAM063ER/L is SAAR. ■ Recommended Cutting Conditions Work Machining Cutting Speed vc (m/min) Feed rate fz (mm/t) Insert ISO material details Lower limit - Recommended - Lower limit - Recommended - Grade Upper limit Upper limit Aluminum Rough 400 to 1700 to 3000 0.05 to 0.13 to 0.20 DA150 alloy (AC) DA2200 N Aluminum Finishing 400 to 1700to 3000 0.04 to 0.10 to 0.15 DA150 alloy (ADC) DA2200 Aluminum Finishing 300 to 450 to 600 0.04 to 0.10 to 0.15 DA150 alloy (A390) DA2200 Warning The cutting conditions above are an approximation. Adjustment may be necessary depending on the machine rigidity, work rigidity, and depth of cut. ■ Performance ● Surface roughness ● Surface roughness M Work material: AC2C vc = 1,500 m/min ap = 0.5 mm Work material: AC2C vc = 1,000 m/min ap = 5.0 mm fz = 0.04–0.15 mm/t Dry ae = 0.1 mm fz = 0.06 mm/t Dry Rz SUMIDIA (Max. height) (µm) 2 0 Rz = 1.4µm (Max. height) D Face machining Side milling Ra = 0.2µm D ①5µm SUMIDIA D SUMIDIA Binderless D D ②6µm SUMICRYSTAL 1 5mm D ③6µm 0 0.04 0.05 0.06 0.08 0.1 ④8µm 5000 mm/t M41

Каталог Sumitomo токарные резцы (державки) для внутреннего точения

Каталог Sumitomo токарные резцы (державки) для внутреннего точения Каталог Sumitomo микроинструмент

Каталог Sumitomo микроинструмент Техническая информация Sumitomo

Техническая информация Sumitomo Каталог Sumitomo модульные системы для револьверных головок токарных станков

Каталог Sumitomo модульные системы для револьверных головок токарных станков Каталог Sumitomo твердосплавные заготовки

Каталог Sumitomo твердосплавные заготовки Каталог Sumitomo фрезы со сменными пластинами

Каталог Sumitomo фрезы со сменными пластинами