Каталог Sumitomo пластины с алмазными вставками Sumidia - страница 2

Навигация

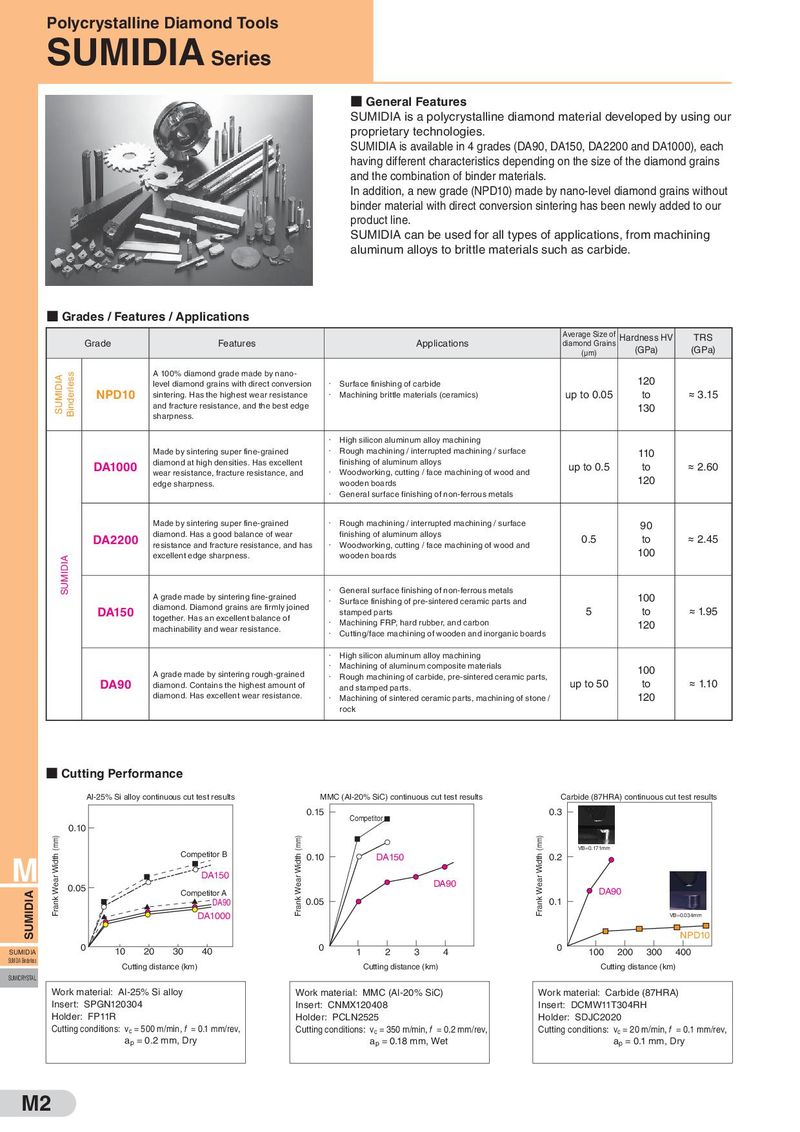

Polycrystalline Diamond Tools SUMIDIA Series ■ General Features SUMIDIA is a polycrystalline diamond material developed by using our proprietary technologies. SUMIDIA is available in 4 grades (DA90, DA150, DA2200 and DA1000), each having different characteristics depending on the size of the diamond grains and the combination of binder materials. In addition, a new grade (NPD10) made by nano-level diamond grains without binder material with direct conversion sintering has been newly added to our product line. SUMIDIA can be used for all types of applications, from machining aluminum alloys to brittle materials such as carbide. ■ Grades / Features / Applications Average Size of Hardness HV TRS Grade Features Applications diamond Grains (GPa) (GPa) (μm) SUMIDIA Binderless A 100% diamond grade made by nano- 120 level diamond grains with direct conversion ・ Surface finishing of carbide NPD10 sintering. Has the highest wear resistance ・ Machining brittle materials (ceramics) up to 0.05 to ≈ 3.15 and fracture resistance, and the best edge 130 sharpness. ・ High silicon aluminum alloy machining Made by sintering super fine-grained ・ Rough machining / interrupted machining / surface 110 DA1000 diamond at high densities. Has excellent finishing of aluminum alloys up to 0.5 to ≈ 2.60 wear resistance, fracture resistance, and ・ Woodworking, cutting / face machining of wood and 120 edge sharpness. wooden boards ・ General surface finishing of non-ferrous metals Made by sintering super fine-grained ・ Rough machining / interrupted machining / surface 90 DA2200 diamond. Has a good balance of wear finishing of aluminum alloys 0.5 to ≈ 2.45 resistance and fracture resistance, and has ・ Woodworking, cutting / face machining of wood and 100 SUMIDIA excellent edge sharpness. wooden boards A grade made by sintering fine-grained ・ General surface finishing of non-ferrous metals 100 diamond. Diamond grains are firmly joined ・ Surface finishing of pre-sintered ceramic parts and DA150 together. Has an excellent balance of stamped parts 5 to ≈ 1.95 machinability and wear resistance. ・ Machining FRP, hard rubber, and carbon 120 ・ Cutting/face machining of wooden and inorganic boards ・ High silicon aluminum alloy machining ・ Machining of aluminum composite materials 100 A grade made by sintering rough-grained ・ Rough machining of carbide, pre-sintered ceramic parts, DA90 diamond. Contains the highest amount of and stamped parts. up to 50 to ≈ 1.10 diamond. Has excellent wear resistance. ・ Machining of sintered ceramic parts, machining of stone / 120 rock ■ Cutting Performance Al-25% Si alloy continuous cut test results MMC (Al-20% SiC) continuous cut test results Carbide (87HRA) continuous cut test results 0.15 Competitor 0.3 0.10 (mm) (mm) (mm) VB=0.171mm M Width Competitor B Width 0.10 DA150 Width 0.2 Frank Wear DA150 Frank Wear DA90 Frank Wear SUMIDIA 0.05 Competitor A DA90 DA90 0.05 0.1 DA1000 VB=0.034mm NPD10 SUMIDIA 0 10 20 30 40 0 1 2 3 4 0 100 200 300 400 SUMIDIA Binderless Cutting distance (km) Cutting distance (km) Cutting distance (km) SUMICRYSTAL Work material: Al-25% Si alloy Work material: MMC (Al-20% SiC) Work material: Carbide (87HRA) Insert: SPGN120304 Insert: CNMX120408 Insert: DCMW11T304RH Holder: FP11R Holder: PCLN2525 Holder: SDJC2020 Cutting conditions: vc = 500 m/min, f = 0.1 mm/rev, Cutting conditions: vc = 350 m/min, f = 0.2 mm/rev, Cutting conditions: vc = 20 m/min, f = 0.1 mm/rev, ap = 0.2 mm, Dry ap = 0.18 mm, Wet ap = 0.1 mm, Dry M2

Каталог Sumitomo токарные резцы (державки) для внутреннего точения

Каталог Sumitomo токарные резцы (державки) для внутреннего точения Каталог Sumitomo микроинструмент

Каталог Sumitomo микроинструмент Техническая информация Sumitomo

Техническая информация Sumitomo Каталог Sumitomo модульные системы для револьверных головок токарных станков

Каталог Sumitomo модульные системы для револьверных головок токарных станков Каталог Sumitomo твердосплавные заготовки

Каталог Sumitomo твердосплавные заготовки Каталог Sumitomo фрезы со сменными пластинами

Каталог Sumitomo фрезы со сменными пластинами