Каталог Sumitomo пластины с алмазными вставками Sumidia - страница 42

Навигация

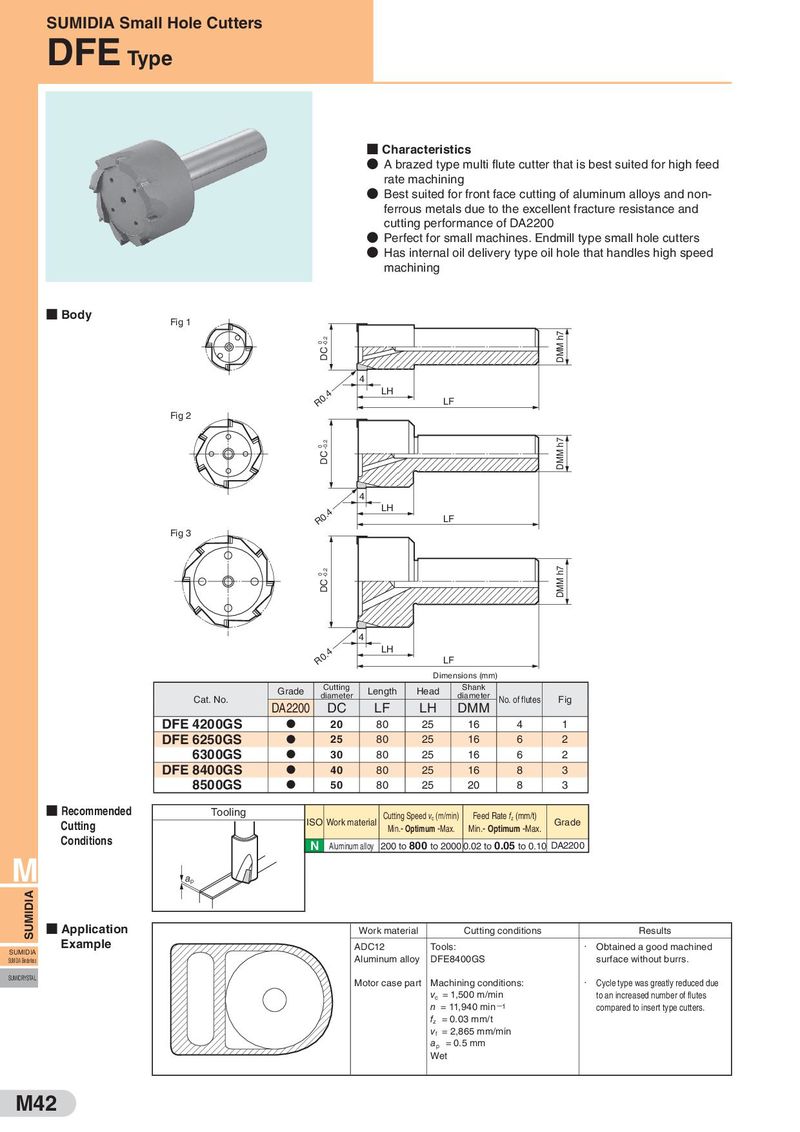

SUMIDIA Small Hole Cutters DFE Type ■ Characteristics ● A brazed type multi flute cutter that is best suited for high feed rate machining ● Best suited for front face cutting of aluminum alloys and non- ferrous metals due to the excellent fracture resistance and cutting performance of DA2200 ● Perfect for small machines. Endmill type small hole cutters ● Has internal oil delivery type oil hole that handles high speed machining ■ Body Fig 1 0 -0.2 DMM h7 DC 4 R0.4 LH LF Fig 2 0 -0.2 DMM h7 DC 4 R0.4 LH LF Fig 3 0 -0.2 DMM h7 DC 4 R0.4 LH LF Dimensions (mm) Grade Cutting Length Head Shank Cat. No. diameter diameter No. of flutes Fig DA2200 DC LF LH DMM DFE 4200GS D 20 80 25 16 4 1 DFE 6250GS D 25 80 25 16 6 2 6300GS D 30 80 25 16 6 2 DFE 8400GS D 40 80 25 16 8 3 8500GS D 50 80 25 20 8 3 ■ Recommended Tooling Cutting Speed vc (m/min) Feed Rate fz (mm/t) Cutting ISO Work material Min.- Optimum -Max. Min.- Optimum -Max. Grade Conditions N Aluminum alloy 200 to 800 to 2000 0.02 to 0.05 to 0.10 DA2200 M ap SUMIDIA ■ Application Work material Cutting conditions Results SUMIDIA Example ADC12 Tools: ・ Obtained a good machined SUMIDIA Binderless Aluminum alloy DFE8400GS surface without burrs. SUMICRYSTAL Motor case part Machining conditions: ・ Cycle type was greatly reduced due vc = 1,500 m/min to an increased number of flutes n = 11,940 min −1 compared to insert type cutters. fz = 0.03 mm/t vf = 2,865 mm/min ap = 0.5 mm Wet M42

Каталог Sumitomo токарные резцы (державки) для внутреннего точения

Каталог Sumitomo токарные резцы (державки) для внутреннего точения Каталог Sumitomo микроинструмент

Каталог Sumitomo микроинструмент Техническая информация Sumitomo

Техническая информация Sumitomo Каталог Sumitomo модульные системы для револьверных головок токарных станков

Каталог Sumitomo модульные системы для револьверных головок токарных станков Каталог Sumitomo твердосплавные заготовки

Каталог Sumitomo твердосплавные заготовки Каталог Sumitomo фрезы со сменными пластинами

Каталог Sumitomo фрезы со сменными пластинами