Каталог Sumitomo пластины с алмазными вставками Sumidia - страница 43

Навигация

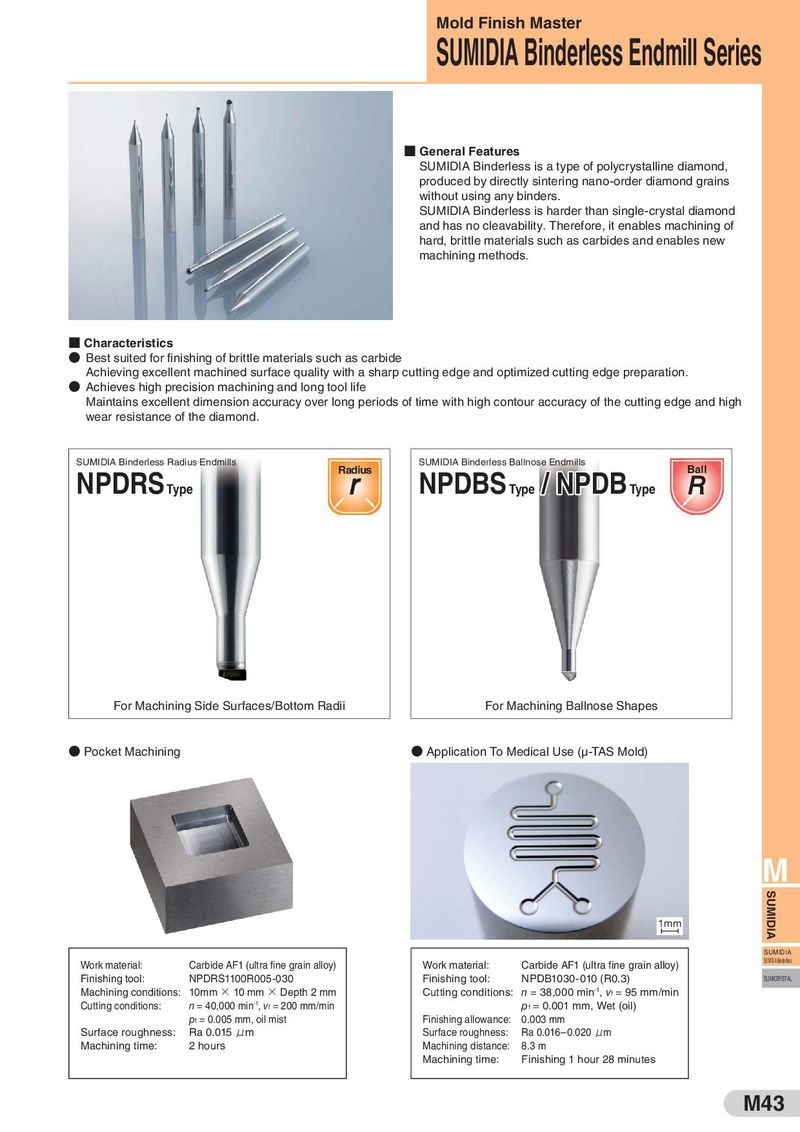

Mold Finish Master SUMIDIA Binderless Endmill Series ■ General Features SUMIDIA Binderless is a type of polycrystalline diamond, produced by directly sintering nano-order diamond grains without using any binders. SUMIDIA Binderless is harder than single-crystal diamond and has no cleavability. Therefore, it enables machining of hard, brittle materials such as carbides and enables new machining methods. ■ Characteristics ● Best suited for finishing of brittle materials such as carbide Achieving excellent machined surface quality with a sharp cutting edge and optimized cutting edge preparation. ● Achieves high precision machining and long tool life Maintains excellent dimension accuracy over long periods of time with high contour accuracy of the cutting edge and high wear resistance of the diamond. SUMIDIA Binderless Radius Endmills rRadius SUMIDIA Binderless Ballnose Endmills Ball NPDRS Type NPDBSType / NPDBType R For Machining Side Surfaces/Bottom Radii For Machining Ballnose Shapes ● Pocket Machining ● Application To Medical Use (µ-TAS Mold) M 1mm SUMIDIA SUMIDIA Work material: Carbide AF1 (ultra fine grain alloy) Work material: Carbide AF1 (ultra fine grain alloy) SUMIDIA Binderless Finishing tool: NPDRS1100R005-030 Finishing tool: NPDB1030-010 (R0.3) SUMICRYSTAL Machining conditions: 10mm × 10 mm × Depth 2 mm Cutting conditions: n = 38,000 min-1, vf = 95 mm/min Cutting conditions: n = 40,000 min-1, vf = 200 mm/min pf = 0.001 mm, Wet (oil) pf = 0.005 mm, oil mist Finishing allowance: 0.003 mm Surface roughness: Ra 0.015 μm Surface roughness: Ra 0.016–0.020 μm Machining time: 2 hours Machining distance: 8.3 m Machining time: Finishing 1 hour 28 minutes M43

Каталог Sumitomo токарные резцы (державки) для внутреннего точения

Каталог Sumitomo токарные резцы (державки) для внутреннего точения Каталог Sumitomo микроинструмент

Каталог Sumitomo микроинструмент Техническая информация Sumitomo

Техническая информация Sumitomo Каталог Sumitomo модульные системы для револьверных головок токарных станков

Каталог Sumitomo модульные системы для револьверных головок токарных станков Каталог Sumitomo твердосплавные заготовки

Каталог Sumitomo твердосплавные заготовки Каталог Sumitomo фрезы со сменными пластинами

Каталог Sumitomo фрезы со сменными пластинами