Каталог Sumitomo пластины с алмазными вставками Sumidia - страница 6

Навигация

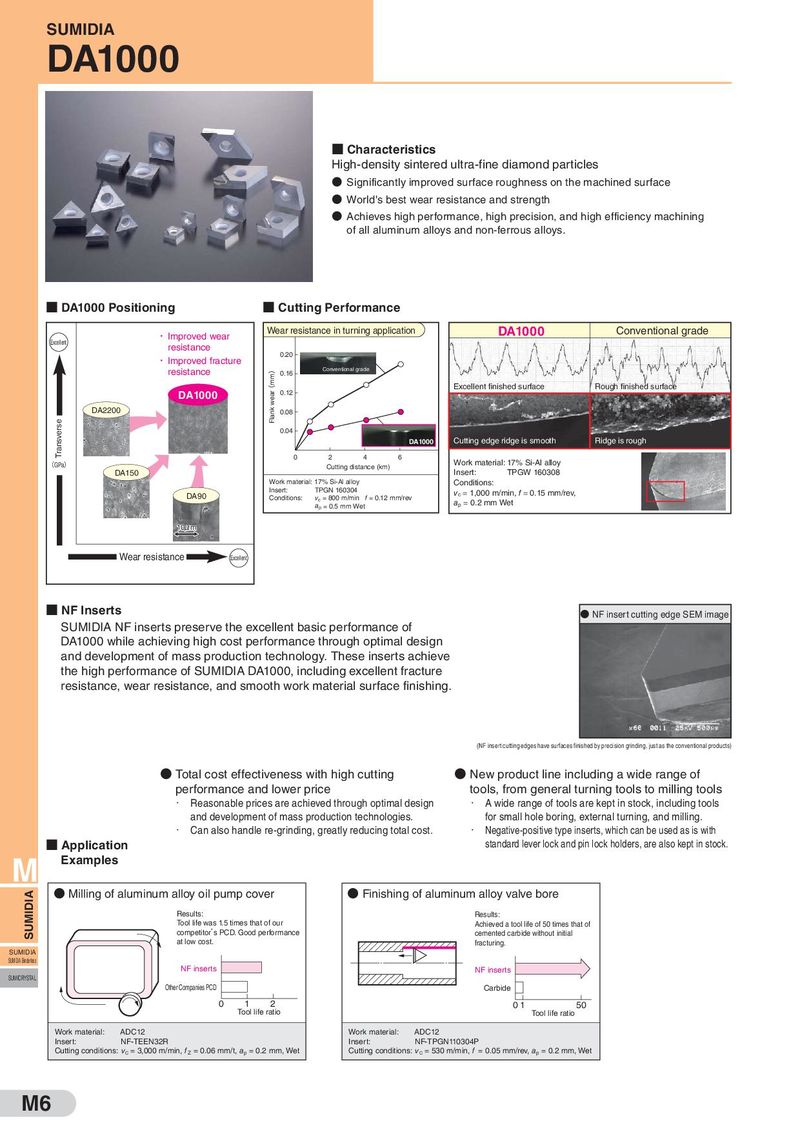

SUMIDIA DA1000 ■ Characteristics High-density sintered ultra-fine diamond particles ● Significantly improved surface roughness on the machined surface ● World's best wear resistance and strength ● Achieves high performance, high precision, and high efficiency machining of all aluminum alloys and non-ferrous alloys. ■ DA1000 Positioning ■ Cutting Performance ・ Improved wear Wear resistance in turning application DA1000 Conventional grade Excellent resistance ・ Improved fracture 0.20 resistance wear(mm) 0.16 Conventional grade 0.12 Excellent nished surface Rough nished surface DA1000 DA2200 Flank 0.08 Transverse 0.04 DA1000 Cutting edge ridge is smooth Ridge is rough 0 2 4 6 Work material: 17% Si-Al alloy (GPa) Cutting distance (km) DA150 Insert: TPGW 160308 Work material: 17% Si-Al alloy Conditions: DA90 Insert: TPGN 160304 vc = 1,000 m/min, f = 0.15 mm/rev, Conditions: vc = 800 m/min f = 0.12 mm/rev ap = 0.2 mm Wet ap = 0.5 mm Wet 10μm Wear resistance Excellent ■ NF Inserts ● NF insert cutting edge SEM image SUMIDIA NF inserts preserve the excellent basic performance of DA1000 while achieving high cost performance through optimal design and development of mass production technology. These inserts achieve the high performance of SUMIDIA DA1000, including excellent fracture resistance, wear resistance, and smooth work material surface finishing. (NF insert cutting edges have surfaces finished by precision grinding, just as the conventional products) ● Total cost effectiveness with high cutting ● New product line including a wide range of performance and lower price tools, from general turning tools to milling tools ・ Reasonable prices are achieved through optimal design ・ A wide range of tools are kept in stock, including tools and development of mass production technologies. for small hole boring, external turning, and milling. ・ Can also handle re-grinding, greatly reducing total cost. ・ Negative-positive type inserts, which can be used as is with ■ Application standard lever lock and pin lock holders, are also kept in stock. M Examples SUMIDIA ● Milling of aluminum alloy oil pump cover ● Finishing of aluminum alloy valve bore Results: Results: Tool life was 1.5 times that of our Achieved a tool life of 50 times that of competitor s PCD. Good performance cemented carbide without initial at low cost. fracturing. SUMIDIA SUMIDIA Binderless NF inserts NF inserts SUMICRYSTAL Other Companies PCD Carbide 0 1 2 01 50 Tool life ratio Tool life ratio Work material: ADC12 Work material: ADC12 Insert: NF-TEEN32R Insert: NF-TPGN110304P Cutting conditions: vC = 3,000 m/min, f Z = 0.06 mm/t, ap = 0.2 mm, Wet Cutting conditions: vC = 530 m/min, f = 0.05 mm/rev, ap = 0.2 mm, Wet M6

Каталог Sumitomo токарные резцы (державки) для внутреннего точения

Каталог Sumitomo токарные резцы (державки) для внутреннего точения Каталог Sumitomo микроинструмент

Каталог Sumitomo микроинструмент Техническая информация Sumitomo

Техническая информация Sumitomo Каталог Sumitomo модульные системы для револьверных головок токарных станков

Каталог Sumitomo модульные системы для револьверных головок токарных станков Каталог Sumitomo твердосплавные заготовки

Каталог Sumitomo твердосплавные заготовки Каталог Sumitomo фрезы со сменными пластинами

Каталог Sumitomo фрезы со сменными пластинами