Каталог Sumitomo инструмент для обработки канавок - страница 42

Навигация

- F001

- F002

- F003

- F004

- F005

- F006

- F007

- F008

- F009

- F010

- F011

- F012

- F013

- F014

- F015

- F016

- F017

- F018

- F019

- F020

- F021

- F022

- F023

- F024

- F025

- F026

- F027

- F028

- F029

- F030

- F031

- F032

- F033

- F034

- F035

- F036

- F037

- F038

- F039

- F040

- F041

- F042

- F043

- F044

- F045

- F046

- F047

- F048

- F049

- F050

- F051

- F052

- F053

- F054

- F055

- F056

- F057

- F058

- F059

- F060

- F061

- F062

- F063

- F064

- F065

- F066

- F067

- F068

- F069

- F070

- F071

- F072

- F073

- F074

- F075

- F076

- F077

- F078

- F079

- F080

- F081

- F082

- F083

- F084

- F085

- F086

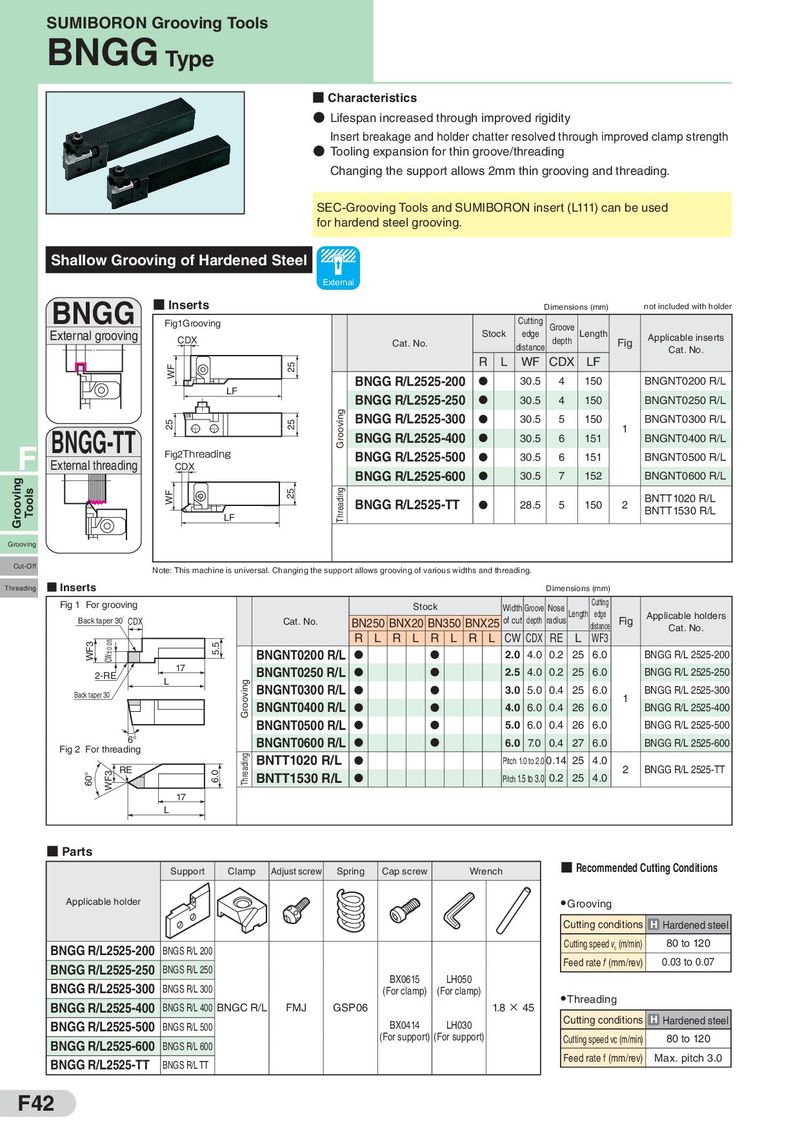

SUMIBORON Grooving Tools BNGG Type ■ Characteristics ● Lifespan increased through improved rigidity Insert breakage and holder chatter resolved through improved clamp strength ● Tooling expansion for thin groove/threading Changing the support allows 2mm thin grooving and threading. SEC-Grooving Tools and SUMIBORON insert (L111) can be used for hardend steel grooving. Shallow Grooving of Hardened Steel External BNGG ■ Inserts Dimensions (mm) not included with holder Fig1Grooving Cutting Groove External grooving CDX Stock edge depth Length Fig Applicable inserts Cat. No. distance Cat. No. WF 25 R L WF CDX LF BNGG R/L2525-200 D 30.5 4 150 BNGNT0200 R/L LF BNGG R/L2525-250 D 30.5 4 150 BNGNT0250 R/L 25 25 Grooving BNGG R/L2525-300 D 30.5 5 150 1 BNGNT0300 R/L BNGG-TT BNGG R/L2525-400 D 30.5 6 151 BNGNT0400 R/L F External threading Fig2Threading BNGG R/L2525-500 D 30.5 6 151 BNGNT0500 R/L CDX BNGG R/L2525-600 Grooving D 30.5 7 152 BNGNT0600 R/L Tools WF 25 Threading BNTT1020 R/L BNGG R/L2525-TT D 28.5 5 150 2 BNTT1530 R/L LF Grooving Cut-Off Note: This machine is universal. Changing the support allows grooving of various widths and threading. Threading ■ Inserts Dimensions (mm) Fig 1 For grooving Stock Width Groove Nose Cutting Back taper 30 CDX Cat. No. BN250 BNX20 BN350 BNX25 of cut depth radius Length edge Fig Applicable holders distance Cat. No. WF3 CW±0.05 5.5 R L R L R L R L CW CDX RE L WF3 BNGNT0200 R/L D D 2.0 4.0 0.2 25 6.0 BNGG R/L 2525-200 2-RE 17 BNGNT0250 R/L D D 2.5 4.0 0.2 25 6.0 BNGG R/L 2525-250 L Grooving BNGNT0300 R/L D D 3.0 5.0 0.4 25 6.0 BNGG R/L 2525-300 Back taper 30 1 BNGNT0400 R/L D D 4.0 6.0 0.4 26 6.0 BNGG R/L 2525-400 BNGNT0500 R/L D D 5.0 6.0 0.4 26 6.0 BNGG R/L 2525-500 6° BNGNT0600 R/L D D 6.0 7.0 0.4 27 6.0 BNGG R/L 2525-600 Fig 2 For threading Threading RE BNTT1020 R/L D Pitch 1.0 to 2.0 0.14 25 4.0 2 BNGG R/L 2525-TT 60° WF3 6.0 BNTT1530 R/L D Pitch 1.5 to 3.0 0.2 25 4.0 17 L ■ Parts Support Clamp Adjust screw Spring Cap screw Wrench ■ Recommended Cutting Conditions Applicable holder ● Grooving Cutting conditions H Hardened steel BNGG R/L2525-200 BNGS R/L 200 Cutting speed vc (m/min) 80 to 120 BNGG R/L2525-250 BNGS R/L 250 Feed rate f (mm/rev) 0.03 to 0.07 BNGG R/L2525-300 BNGS R/L 300 BX0615 LH050 (For clamp) (For clamp) ● Threading BNGG R/L2525-400 BNGS R/L 400 BNGC R/L FMJ GSP06 1.8 × 45 BNGG R/L2525-500 BNGS R/L 500 BX0414 LH030 Cutting conditions H Hardened steel BNGG R/L2525-600 BNGS R/L 600 (For support) (For support) Cutting speed vc (m/min) 80 to 120 BNGG R/L2525-TT BNGS R/L TT Feed rate f (mm/rev) Max. pitch 3.0 F42

Каталог Sumitomo пластины с алмазными вставками Sumidia

Каталог Sumitomo пластины с алмазными вставками Sumidia Каталог Sumitomo микроинструмент

Каталог Sumitomo микроинструмент Общий каталог Sumitomo 2012

Общий каталог Sumitomo 2012 Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal Каталог Sumitomo пластины с кубическим нитридом бора Sumiboron

Каталог Sumitomo пластины с кубическим нитридом бора Sumiboron Общий каталог Sumitomo 2018 - 2019

Общий каталог Sumitomo 2018 - 2019