Каталог Sumitomo инструмент для обработки канавок - страница 21

Навигация

- F001

- F002

- F003

- F004

- F005

- F006

- F007

- F008

- F009

- F010

- F011

- F012

- F013

- F014

- F015

- F016

- F017

- F018

- F019

- F020

- F021

- F022

- F023

- F024

- F025

- F026

- F027

- F028

- F029

- F030

- F031

- F032

- F033

- F034

- F035

- F036

- F037

- F038

- F039

- F040

- F041

- F042

- F043

- F044

- F045

- F046

- F047

- F048

- F049

- F050

- F051

- F052

- F053

- F054

- F055

- F056

- F057

- F058

- F059

- F060

- F061

- F062

- F063

- F064

- F065

- F066

- F067

- F068

- F069

- F070

- F071

- F072

- F073

- F074

- F075

- F076

- F077

- F078

- F079

- F080

- F081

- F082

- F083

- F084

- F085

- F086

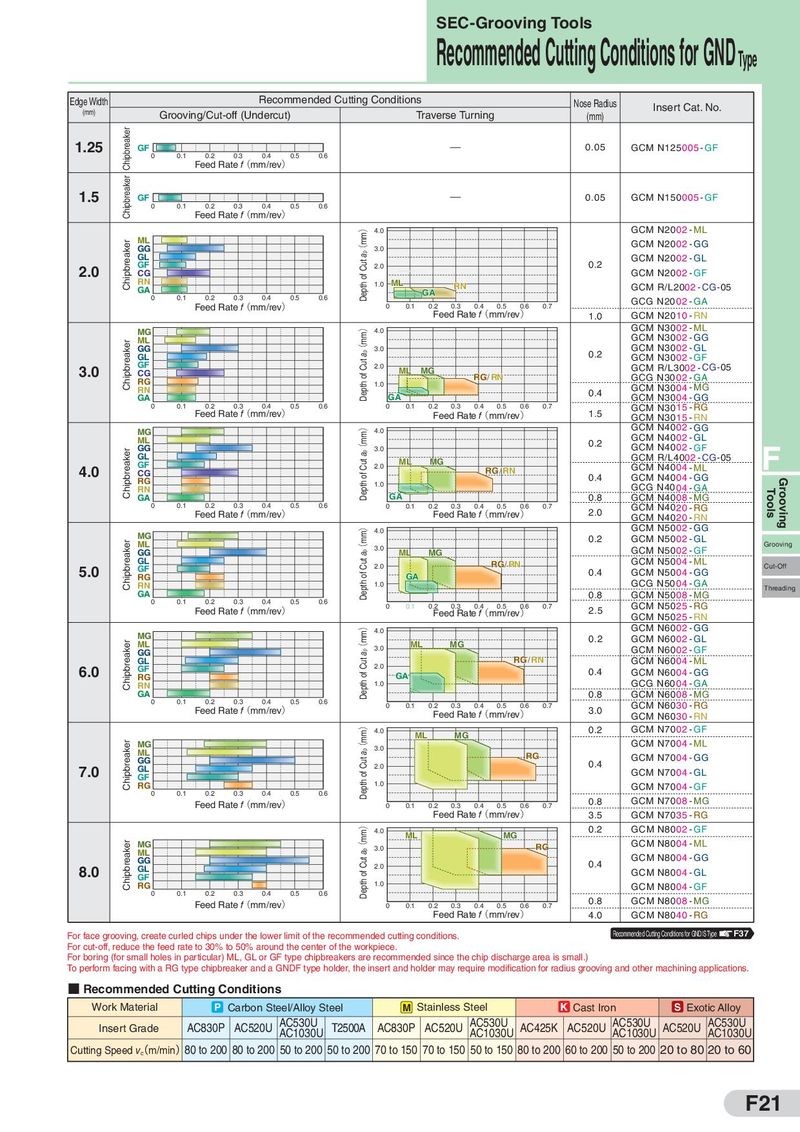

SEC-Grooving Tools Recommended Cutting Conditions for GNDType Edge Width Recommended Cutting Conditions Nose Radius Insert Cat. No. (mm) Grooving/Cut-off (Undercut) Traverse Turning (mm) 1.25 Chipbreaker GF Q 0.05 GCM N125005- GF 0 0.1 0.2 0.3 0.4 0.5 0.6 Feed Rate f(mm/rev) 1.5 Chipbreaker GF Q 0.05 GCM N150005- GF 0 0.1 0.2 0.3 0.4 0.5 0.6 Feed Rate f(mm/rev) Depth of Cut ap(mm) 4.0 GCM N2002 - ML Chipbreaker ML GCM N2002 - GG GG 3.0 GL 0.2 GCM N2002 - GL 2.0 GF 2.0 GCM N2002 - GF CG RN 1.0 ML RN GCM R/L2002 - CG-05 GA GA 0 0.1 0.2 0.3 0.4 0.5 0.6 GCG N2002 - GA Feed Rate f(mm/rev) 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 Feed Rate f(mm/rev) 1.0 GCM N2010 - RN MG Depth of Cut ap(mm) 4.0 GCM N3002 - ML Chipbreaker ML GCM N3002 - GG GG 3.0 0.2 GCM N3002 - GL GL GCM N3002 - GF 3.0 GF 2.0 ML MG GCM R/L3002 - CG-05 CG RG/ RN GCG N3002 - GA RG 1.0 GCM N3004 - MG RN GA 0.4 GCM N3004 - GG GA 0 0.1 0.2 0.3 0.4 0.5 0.6 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 GCM N3015 - RG Feed Rate f(mm/rev) Feed Rate f(mm/rev) 1.5 GCM N3015 - RN MG Depth of Cut ap(mm) 4.0 GCM N4002 - GG ML 0.2 GCM N4002 - GL Chipbreaker GG 3.0 GCM N4002 - GF F GL ML MG GCM R/L4002 - CG-05 4.0 GF 2.0 RG/ RN GCM N4004 - ML CG 0.4 GCM N4004 - GG Grooving RG 1.0 GCG N4004 - GA RN GA 0.8 GCM N4008 - MG Tools GA 0 0.1 0.2 0.3 0.4 0.5 0.6 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 2.0 GCM N4020 - RG Feed Rate f(mm/rev) Feed Rate f(mm/rev) GCM N4020 - RN MG Depth of Cut ap(mm) 4.0 GCM N5002 - GG Chipbreaker ML 0.2 GCM N5002 - GL Grooving GG 3.0 ML MG GCM N5002 - GF GL 2.0 RG/ RN GCM N5004 - ML Cut-Off 5.0 GF GA 0.4 GCM N5004 - GG RG 1.0 GCG N5004 - GA RN Threading GA 0.8 GCM N5008 - MG 0 0.1 0.2 0.3 0.4 0.5 0.6 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 GCM N5025 - RG Feed Rate f(mm/rev) Feed Rate f(mm/rev) 2.5 GCM N5025 - RN MG Depth of Cut ap(mm) 4.0 GCM N6002 - GG Chipbreaker ML ML MG 0.2 GCM N6002 - GL GG 3.0 GCM N6002 - GF GL 2.0 RG/ RN GCM N6004 - ML 6.0 GF GA 0.4 GCM N6004 - GG RG 1.0 GCG N6004 - GA RN GA 0.8 GCM N6008 - MG 0 0.1 0.2 0.3 0.4 0.5 0.6 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 GCM N6030 - RG Feed Rate f(mm/rev) Feed Rate f(mm/rev) 3.0 GCM N6030 - RN Depth of Cut ap(mm) 4.0 ML MG 0.2 GCM N7002 - GF Chipbreaker MG 3.0 GCM N7004 - ML ML RG GCM N7004 - GG GG 2.0 0.4 7.0 GL GCM N7004 - GL GF 1.0 RG GCM N7004 - GF 0 0.1 0.2 0.3 0.4 0.5 0.6 Feed Rate f(mm/rev) 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 GCM N7008 - MG Feed Rate f(mm/rev) 3.5 GCM N7035 - RG Depth of Cut ap(mm) 4.0 ML MG 0.2 GCM N8002 - GF Chipbreaker MG 3.0 RG GCM N8004 - ML ML GCM N8004 - GG GG 2.0 0.4 8.0 GL GCM N8004 - GL GF 1.0 RG GCM N8004 - GF 0 0.1 0.2 0.3 0.4 0.5 0.6 Feed Rate f(mm/rev) 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 GCM N8008 - MG Feed Rate f(mm/rev) 4.0 GCM N8040 - RG For face grooving, create curled chips under the lower limit of the recommended cutting conditions. Recommended Cutting Conditions for GNDIS Type F37 For cut-off, reduce the feed rate to 30% to 50% around the center of the workpiece. For boring (for small holes in particular) ML, GL or GF type chipbreakers are recommended since the chip discharge area is small.) To perform facing with a RG type chipbreaker and a GNDF type holder, the insert and holder may require modification for radius grooving and other machining applications. ■ Recommended Cutting Conditions Work Material P Carbon Steel/Alloy Steel M Stainless Steel K Cast Iron S Exotic Alloy Insert Grade AC830P AC520U AC530U T2500A AC830P AC520U AC530U AC425K AC520U AC530U AC520U AC530U AC1030U AC1030U AC1030U AC1030U Cutting Speed v(c m/min)80 to 200 80 to 200 50 to 200 50 to 200 70 to 150 70 to 150 50 to 150 80 to 200 60 to 200 50 to 200 20 to 80 20 to 60 F21

Каталог Sumitomo пластины с алмазными вставками Sumidia

Каталог Sumitomo пластины с алмазными вставками Sumidia Каталог Sumitomo микроинструмент

Каталог Sumitomo микроинструмент Общий каталог Sumitomo 2012

Общий каталог Sumitomo 2012 Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal Каталог Sumitomo пластины с кубическим нитридом бора Sumiboron

Каталог Sumitomo пластины с кубическим нитридом бора Sumiboron Общий каталог Sumitomo 2018 - 2019

Общий каталог Sumitomo 2018 - 2019