Каталог Sumitomo инструмент для обработки канавок - страница 4

Навигация

- F001

- F002

- F003

- F004

- F005

- F006

- F007

- F008

- F009

- F010

- F011

- F012

- F013

- F014

- F015

- F016

- F017

- F018

- F019

- F020

- F021

- F022

- F023

- F024

- F025

- F026

- F027

- F028

- F029

- F030

- F031

- F032

- F033

- F034

- F035

- F036

- F037

- F038

- F039

- F040

- F041

- F042

- F043

- F044

- F045

- F046

- F047

- F048

- F049

- F050

- F051

- F052

- F053

- F054

- F055

- F056

- F057

- F058

- F059

- F060

- F061

- F062

- F063

- F064

- F065

- F066

- F067

- F068

- F069

- F070

- F071

- F072

- F073

- F074

- F075

- F076

- F077

- F078

- F079

- F080

- F081

- F082

- F083

- F084

- F085

- F086

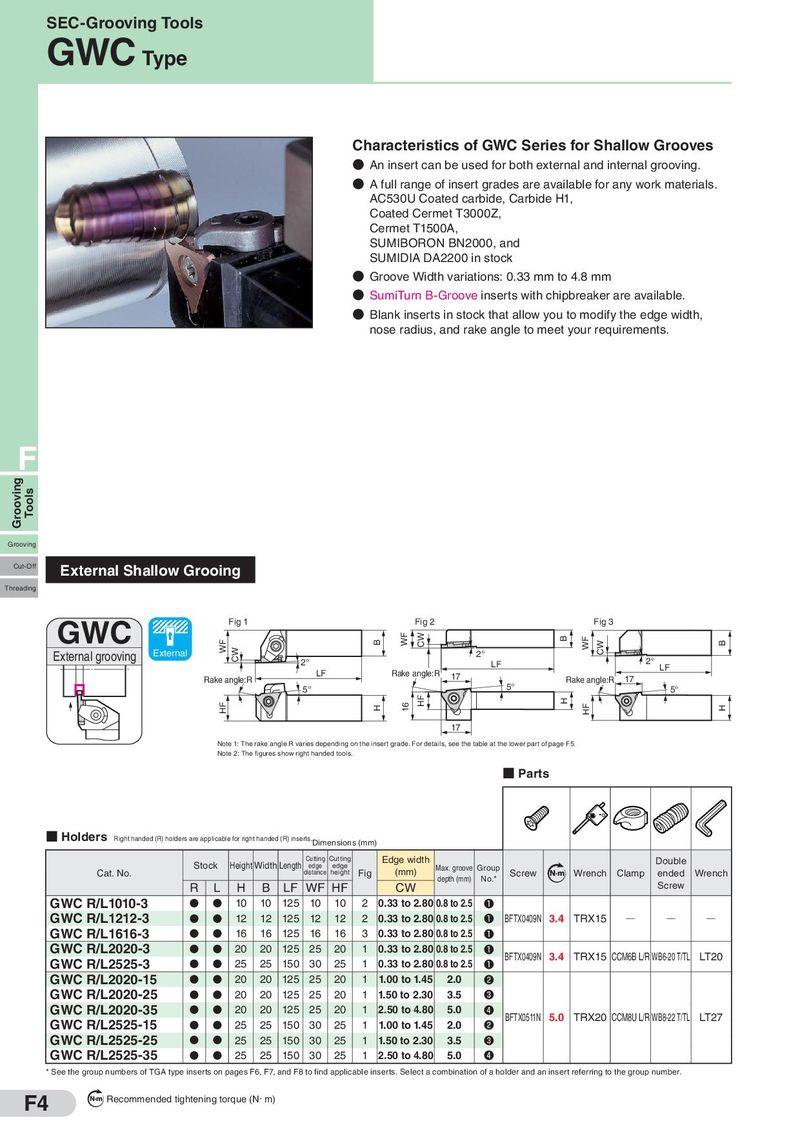

SEC-Grooving Tools GWC Type Characteristics of GWC Series for Shallow Grooves ● An insert can be used for both external and internal grooving. ● A full range of insert grades are available for any work materials. AC530U Coated carbide, Carbide H1, Coated Cermet T3000Z, Cermet T1500A, SUMIBORON BN2000, and SUMIDIA DA2200 in stock ● Groove Width variations: 0.33 mm to 4.8 mm ● SumiTurn B-Groove inserts with chipbreaker are available. ● Blank inserts in stock that allow you to modify the edge width, nose radius, and rake angle to meet your requirements. F Grooving Tools Grooving Cut-Off External Shallow Grooing Threading GWC Fig 1 Fig 2 Fig 3 WF B WF CW B WF CW B External grooving External CW 2° 2° 2° LF LF Rake angle:R LF Rake angle:R 17 Rake angle:R 17 5° 5° 5° HF 16 HF H HF H H 17 Note 1: The rake angle R varies depending on the insert grade. For details, see the table at the lower part of page F5. Note 2: The figures show right handed tools. ■ Parts ■ Holders Right handed (R) holders are applicable for right handed (R) inserts.Dimensions (mm) Stock Height Width Length Cutting Cutting Edge width Double edge edge (mm) Max. groove Group Cat. No. distance height Fig depth (mm) No.* Screw Nm Wrench Clamp ended Wrench R L H B LF WF HF CW Screw GWC R/L1010-3 D D 10 10 125 10 10 2 0.33 to 2.80 0.8 to 2.5 ❶ GWC R/L1212-3 D D 12 12 125 12 12 2 0.33 to 2.80 0.8 to 2.5 ❶ BFTX0409N 3.4 TRX15 Q Q Q GWC R/L1616-3 D D 16 16 125 16 16 3 0.33 to 2.80 0.8 to 2.5 ❶ GWC R/L2020-3 D D 20 20 125 25 20 1 0.33 to 2.80 0.8 to 2.5 ❶ BFTX0409N 3.4 TRX15 CCM6B L/R WB6-20 T/TL LT20 GWC R/L2525-3 D D 25 25 150 30 25 1 0.33 to 2.80 0.8 to 2.5 ❶ GWC R/L2020-15 D D 20 20 125 25 20 1 1.00 to 1.45 2.0 ❷ GWC R/L2020-25 D D 20 20 125 25 20 1 1.50 to 2.30 3.5 ❸ GWC R/L2020-35 D D 20 20 125 25 20 1 2.50 to 4.80 5.0 ❹ BFTX0511N 5.0 TRX20 CCM8U L/R WB8-22 T/TL LT27 GWC R/L2525-15 D D 25 25 150 30 25 1 1.00 to 1.45 2.0 ❷ GWC R/L2525-25 D D 25 25 150 30 25 1 1.50 to 2.30 3.5 ❸ GWC R/L2525-35 D D 25 25 150 30 25 1 2.50 to 4.80 5.0 ❹ * See the group numbers of TGA type inserts on pages F6, F7, and F8 to find applicable inserts. Select a combination of a holder and an insert referring to the group number. F4 N m Recommended tightening torque (N・m)

Каталог Sumitomo пластины с алмазными вставками Sumidia

Каталог Sumitomo пластины с алмазными вставками Sumidia Каталог Sumitomo микроинструмент

Каталог Sumitomo микроинструмент Общий каталог Sumitomo 2012

Общий каталог Sumitomo 2012 Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal Каталог Sumitomo пластины с кубическим нитридом бора Sumiboron

Каталог Sumitomo пластины с кубическим нитридом бора Sumiboron Общий каталог Sumitomo 2018 - 2019

Общий каталог Sumitomo 2018 - 2019