Каталог Sumitomo инструмент для обработки канавок - страница 35

Навигация

- F001

- F002

- F003

- F004

- F005

- F006

- F007

- F008

- F009

- F010

- F011

- F012

- F013

- F014

- F015

- F016

- F017

- F018

- F019

- F020

- F021

- F022

- F023

- F024

- F025

- F026

- F027

- F028

- F029

- F030

- F031

- F032

- F033

- F034

- F035

- F036

- F037

- F038

- F039

- F040

- F041

- F042

- F043

- F044

- F045

- F046

- F047

- F048

- F049

- F050

- F051

- F052

- F053

- F054

- F055

- F056

- F057

- F058

- F059

- F060

- F061

- F062

- F063

- F064

- F065

- F066

- F067

- F068

- F069

- F070

- F071

- F072

- F073

- F074

- F075

- F076

- F077

- F078

- F079

- F080

- F081

- F082

- F083

- F084

- F085

- F086

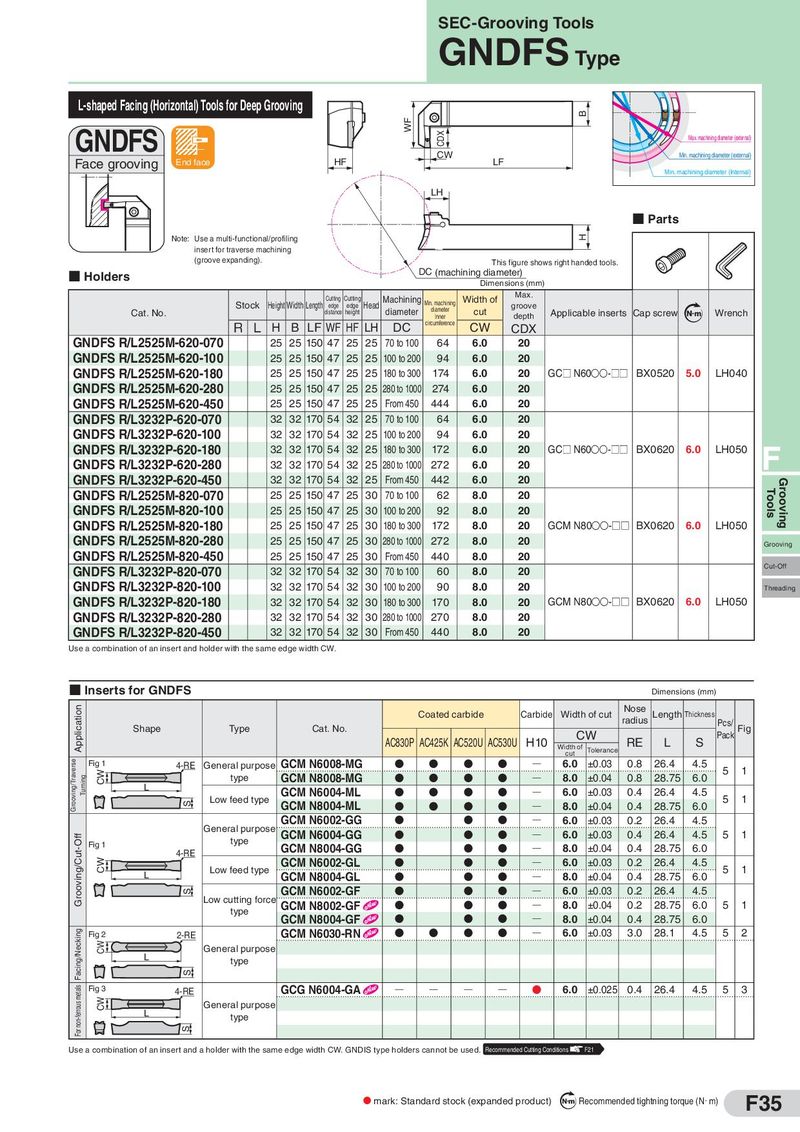

SEC-Grooving Tools GNDFS Type L-shaped Facing (Horizontal) Tools for Deep Grooving B GNDFS WF CDX Max. machining diameter (external) Face grooving End face HF CW LF Min. machining diameter (external) Min. machining diameter (Internal) LH ■ Parts Note: Use a multi-functional/profiling H insert for traverse machining (groove expanding). This figure shows right handed tools. ■ Holders DC (machining diameter) Dimensions (mm) Cutting Cutting Machining Min. machining Width of Max. Stock Height Width Length edge edge Head diameter diameter cut groove Cat. No. distance height Inner depth Applicable inserts Cap screw Nm Wrench R L H B LF WF HF LH DC circumference CW CDX GNDFS R/L2525M-620-070 25 25 150 47 25 25 70 to 100 64 6.0 20 GNDFS R/L2525M-620-100 25 25 150 47 25 25 100 to 200 94 6.0 20 GNDFS R/L2525M-620-180 25 25 150 47 25 25 180 to 300 174 6.0 20 GC□ N60SS-□□ BX0520 5.0 LH040 GNDFS R/L2525M-620-280 25 25 150 47 25 25 280 to 1000 274 6.0 20 GNDFS R/L2525M-620-450 25 25 150 47 25 25 From 450 444 6.0 20 GNDFS R/L3232P-620-070 32 32 170 54 32 25 70 to 100 64 6.0 20 GNDFS R/L3232P-620-100 32 32 170 54 32 25 100 to 200 94 6.0 20 GNDFS R/L3232P-620-180 32 32 170 54 32 25 180 to 300 172 6.0 20 GC□ N60SS-□□ BX0620 6.0 LH050 F GNDFS R/L3232P-620-280 32 32 170 54 32 25 280 to 1000 272 6.0 20 GNDFS R/L3232P-620-450 32 32 170 54 32 25 From 450 442 6.0 20 Grooving GNDFS R/L2525M-820-070 25 25 150 47 25 30 70 to 100 62 8.0 20 Tools GNDFS R/L2525M-820-100 25 25 150 47 25 30 100 to 200 92 8.0 20 GNDFS R/L2525M-820-180 25 25 150 47 25 30 180 to 300 172 8.0 20 GCM N80SS-□□ BX0620 6.0 LH050 GNDFS R/L2525M-820-280 25 25 150 47 25 30 280 to 1000 272 8.0 20 Grooving GNDFS R/L2525M-820-450 25 25 150 47 25 30 From 450 440 8.0 20 GNDFS R/L3232P-820-070 32 32 170 54 32 30 70 to 100 60 8.0 20 Cut-Off GNDFS R/L3232P-820-100 32 32 170 54 32 30 100 to 200 90 8.0 20 Threading GNDFS R/L3232P-820-180 32 32 170 54 32 30 180 to 300 170 8.0 20 GCM N80SS-□□ BX0620 6.0 LH050 GNDFS R/L3232P-820-280 32 32 170 54 32 30 280 to 1000 270 8.0 20 GNDFS R/L3232P-820-450 32 32 170 54 32 30 From 450 440 8.0 20 Use a combination of an insert and holder with the same edge width CW. ■ Inserts for GNDFS Dimensions (mm) Application Coated carbide Carbide Width of cut Nose Length Thickness Shape Type Cat. No. radius Pcs/ Fig AC830P AC425K AC520U AC530U H10 CW RE L S Pack Width of Tolerance cut Grooving/Traverse Fig 1 4-RE General purpose GCM N6008-MG D D D D Q 6.0 ±0.03 0.8 26.4 4.5 5 1 Turning CW type GCM N8008-MG D D D D Q 8.0 ±0.04 0.8 28.75 6.0 L GCM N6004-ML D D D D Q 6.0 ±0.03 0.4 26.4 4.5 S Low feed type GCM N8004-ML D D D D Q 8.0 ±0.04 0.4 28.75 6.0 5 1 General purpose GCM N6002-GG D D D Q 6.0 ±0.03 0.2 26.4 4.5 Grooving/Cut-Off type GCM N6004-GG D D D Q 6.0 ±0.03 0.4 26.4 4.5 5 1 Fig 1 GCM N8004-GG D D D Q 8.0 ±0.04 0.4 28.75 6.0 CW 4-RE GCM N6002-GL Low feed type D D D Q 6.0 ±0.03 0.2 26.4 4.5 5 1 L GCM N8004-GL D D D Q 8.0 ±0.04 0.4 28.75 6.0 S GCM N6002-GF D D D Q 6.0 ±0.03 0.2 26.4 4.5 Low cutting force GCM N8002-GF D D D Q 8.0 ±0.04 0.2 28.75 6.0 5 1 type GCM N8004-GF D D D Q 8.0 ±0.04 0.4 28.75 6.0 Facing/Necking Fig 2 2-RE GCM N6030-RN D D D D Q 6.0 ±0.03 3.0 28.1 4.5 5 2 CW General purpose L type S For non-ferrous metals Fig 3 4-RE GCG N6004-GA Q Q Q Q D 6.0 ±0.025 0.4 26.4 4.5 5 3 CW L General purpose type S Use a combination of an insert and a holder with the same edge width CW. GNDIS type holders cannot be used. Recommended Cutting Conditions F21 D mark: Standard stock (expanded product) N m Recommended tightning torque (N・m) F35

Каталог Sumitomo пластины с алмазными вставками Sumidia

Каталог Sumitomo пластины с алмазными вставками Sumidia Каталог Sumitomo микроинструмент

Каталог Sumitomo микроинструмент Общий каталог Sumitomo 2012

Общий каталог Sumitomo 2012 Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal Каталог Sumitomo пластины с кубическим нитридом бора Sumiboron

Каталог Sumitomo пластины с кубическим нитридом бора Sumiboron Общий каталог Sumitomo 2018 - 2019

Общий каталог Sumitomo 2018 - 2019