Каталог Sumitomo инструмент для обработки канавок - страница 12

Навигация

- F001

- F002

- F003

- F004

- F005

- F006

- F007

- F008

- F009

- F010

- F011

- F012

- F013

- F014

- F015

- F016

- F017

- F018

- F019

- F020

- F021

- F022

- F023

- F024

- F025

- F026

- F027

- F028

- F029

- F030

- F031

- F032

- F033

- F034

- F035

- F036

- F037

- F038

- F039

- F040

- F041

- F042

- F043

- F044

- F045

- F046

- F047

- F048

- F049

- F050

- F051

- F052

- F053

- F054

- F055

- F056

- F057

- F058

- F059

- F060

- F061

- F062

- F063

- F064

- F065

- F066

- F067

- F068

- F069

- F070

- F071

- F072

- F073

- F074

- F075

- F076

- F077

- F078

- F079

- F080

- F081

- F082

- F083

- F084

- F085

- F086

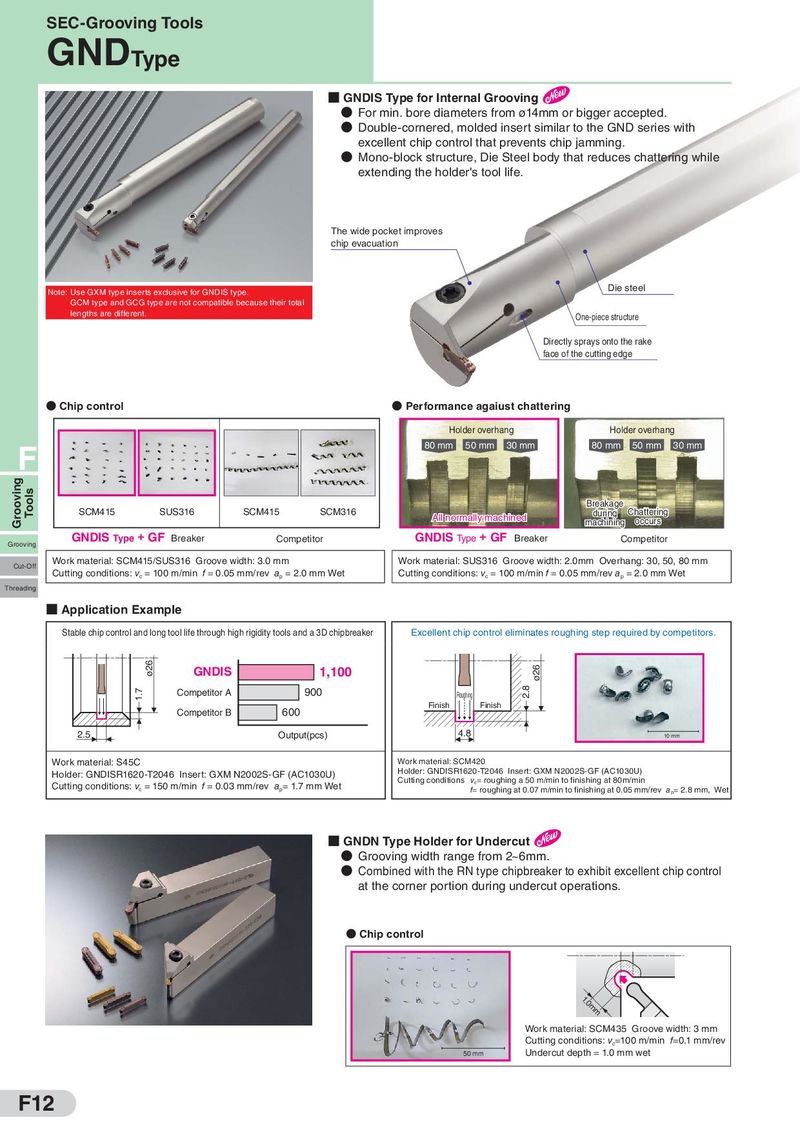

SEC-Grooving Tools GNDType ■ GNDIS Type for Internal Grooving ● For min. bore diameters from ø14mm or bigger accepted. ● Double-cornered, molded insert similar to the GND series with excellent chip control that prevents chip jamming. ● Mono-block structure, Die Steel body that reduces chattering while extending the holder's tool life. The wide pocket improves chip evacuation Note: Use GXM type inserts exclusive for GNDIS type. Die steel GCM type and GCG type are not compatible because their total lengths are different. One-piece structure Directly sprays onto the rake face of the cutting edge ● Chip control ● Performance agaiust chattering Holder overhang Holder overhang F 80 mm 50 mm 30 mm 80 mm 50 mm 30 mm Grooving Tools Breakage Chattering SCM415 SUS316 SCM415 SCM316 All normally machined during machining occurs Grooving GNDIS Type + GF Breaker Competitor GNDIS Type + GF Breaker Competitor Cut-Off Work material: SCM415/SUS316 Groove width: 3.0 mm Work material: SUS316 Groove width: 2.0mm Overhang: 30, 50, 80 mm Cutting conditions: vc = 100 m/min f = 0.05 mm/rev ap = 2.0 mm Wet Cutting conditions: vc = 100 m/min f = 0.05 mm/rev ap = 2.0 mm Wet Threading ■ Application Example Stable chip control and long tool life through high rigidity tools and a 3D chipbreaker Excellent chip control eliminates roughing step required by competitors. ø26 GNDIS 1,100 ø26 1.7 Competitor A 900 Roughing 2.8 Competitor B 600 Finish Finish 2.5 Output(pcs) 4.8 10 mm Work material: S45C Work material: SCM420 Holder: GNDISR1620-T2046 Insert: GXM N2002S-GF (AC1030U) Holder: GNDISR1620-T2046 Insert: GXM N2002S-GF (AC1030U) Cutting conditions: vc = 150 m/min f = 0.03 mm/rev ap= 1.7 mm Wet Cutting conditions vc= roughing a 50 m/min to finishing at 80m/min f= roughing at 0.07 m/min to finishing at 0.05 mm/rev ap= 2.8 mm, Wet ■ GNDN Type Holder for Undercut ● Grooving width range from 2~6mm. ● Combined with the RN type chipbreaker to exhibit excellent chip control at the corner portion during undercut operations. ● Chip control 1.0mm Work material: SCM435 Groove width: 3 mm Cutting conditions: vc=100 m/min f=0.1 mm/rev 50 mm Undercut depth = 1.0 mm wet F12

Каталог Sumitomo пластины с алмазными вставками Sumidia

Каталог Sumitomo пластины с алмазными вставками Sumidia Каталог Sumitomo микроинструмент

Каталог Sumitomo микроинструмент Общий каталог Sumitomo 2012

Общий каталог Sumitomo 2012 Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal Каталог Sumitomo пластины с кубическим нитридом бора Sumiboron

Каталог Sumitomo пластины с кубическим нитридом бора Sumiboron Общий каталог Sumitomo 2018 - 2019

Общий каталог Sumitomo 2018 - 2019