Каталог Sumitomo инструмент для обработки канавок - страница 39

Навигация

- F001

- F002

- F003

- F004

- F005

- F006

- F007

- F008

- F009

- F010

- F011

- F012

- F013

- F014

- F015

- F016

- F017

- F018

- F019

- F020

- F021

- F022

- F023

- F024

- F025

- F026

- F027

- F028

- F029

- F030

- F031

- F032

- F033

- F034

- F035

- F036

- F037

- F038

- F039

- F040

- F041

- F042

- F043

- F044

- F045

- F046

- F047

- F048

- F049

- F050

- F051

- F052

- F053

- F054

- F055

- F056

- F057

- F058

- F059

- F060

- F061

- F062

- F063

- F064

- F065

- F066

- F067

- F068

- F069

- F070

- F071

- F072

- F073

- F074

- F075

- F076

- F077

- F078

- F079

- F080

- F081

- F082

- F083

- F084

- F085

- F086

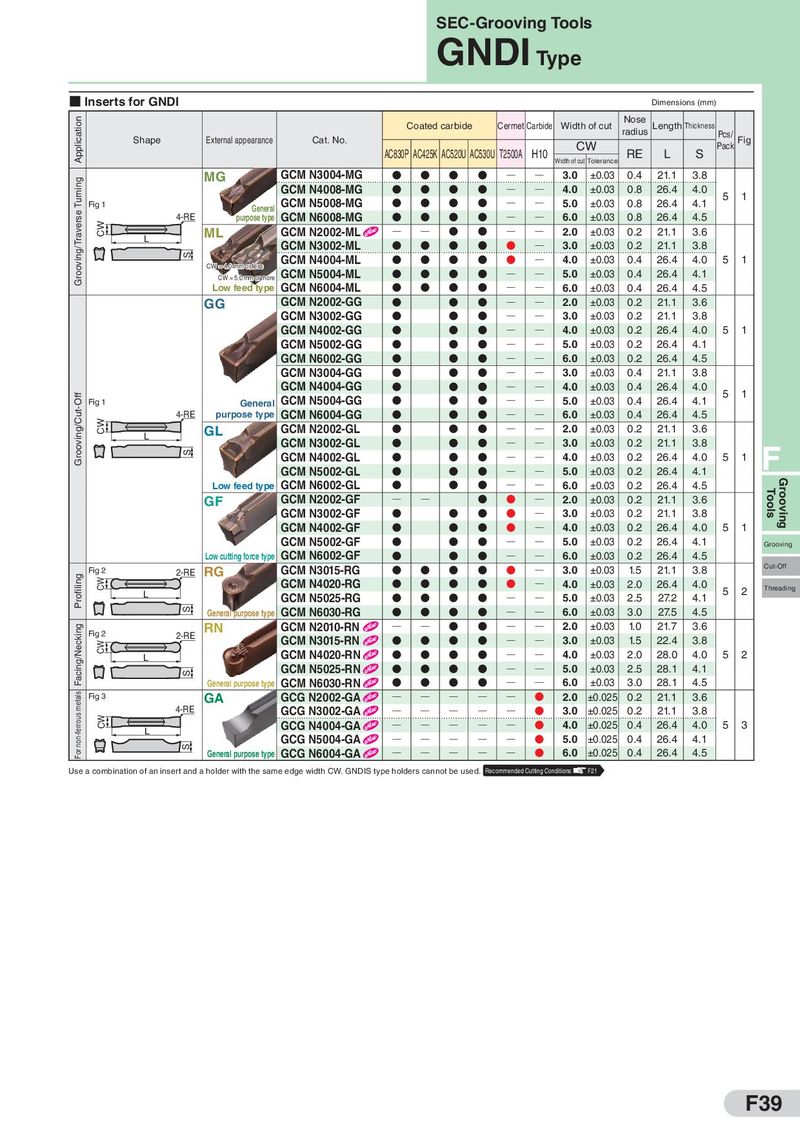

SEC-Grooving Tools GNDI Type ■ Inserts for GNDI Dimensions (mm) Application Coated carbide Cermet Carbide Width of cut Nose Length Thickness Shape External appearance Cat. No. radius Pcs/ Fig AC830P AC425K AC520U AC530U T2500A H10 CW RE L S Pack Width of cut Tolerance Grooving/Traverse Turning MG GCM N3004-MG D D D D Q Q 3.0 ±0.03 0.4 21.1 3.8 GCM N4008-MG D D D D Q Q 4.0 ±0.03 0.8 26.4 4.0 5 1 Fig 1 General GCM N5008-MG D D D D Q Q 5.0 ±0.03 0.8 26.4 4.1 CW 4-RE purpose type GCM N6008-MG D D D D Q Q 6.0 ±0.03 0.8 26.4 4.5 L ML GCM N2002-ML Q Q D D Q Q 2.0 ±0.03 0.2 21.1 3.6 GCM N3002-ML D D D D D Q 3.0 ±0.03 0.2 21.1 3.8 S GCM N4004-ML D D D D D Q 4.0 ±0.03 0.4 26.4 4.0 5 1 CW = 4.0 mm or less GCM N5004-ML 5.0 ±0.03 0.4 26.4 4.1 CW = 5.0 mm or more D D D D Q Q Low feed type GCM N6004-ML D D D D Q Q 6.0 ±0.03 0.4 26.4 4.5 GG GCM N2002-GG D D D Q Q 2.0 ±0.03 0.2 21.1 3.6 GCM N3002-GG D D D Q Q 3.0 ±0.03 0.2 21.1 3.8 GCM N4002-GG D D D Q Q 4.0 ±0.03 0.2 26.4 4.0 5 1 GCM N5002-GG D D D Q Q 5.0 ±0.03 0.2 26.4 4.1 GCM N6002-GG D D D Q Q 6.0 ±0.03 0.2 26.4 4.5 GCM N3004-GG D D D Q Q 3.0 ±0.03 0.4 21.1 3.8 GCM N4004-GG D D D Q Q 4.0 ±0.03 0.4 26.4 4.0 5 1 Grooving/Cut-Off Fig 1 General GCM N5004-GG D D D Q Q 5.0 ±0.03 0.4 26.4 4.1 CW 4-RE purpose type GCM N6004-GG D D D Q Q 6.0 ±0.03 0.4 26.4 4.5 L GL GCM N2002-GL D D D Q Q 2.0 ±0.03 0.2 21.1 3.6 GCM N3002-GL D D D Q Q 3.0 ±0.03 0.2 21.1 3.8 F S GCM N4002-GL D D D Q Q 4.0 ±0.03 0.2 26.4 4.0 5 1 GCM N5002-GL D D D Q Q 5.0 ±0.03 0.2 26.4 4.1 Low feed type GCM N6002-GL D D D Q Q 6.0 ±0.03 0.2 26.4 4.5 Tools Grooving GF GCM N2002-GF Q Q D D Q 2.0 ±0.03 0.2 21.1 3.6 GCM N3002-GF D D D D Q 3.0 ±0.03 0.2 21.1 3.8 GCM N4002-GF D D D D Q 4.0 ±0.03 0.2 26.4 4.0 5 1 GCM N5002-GF D D D Q Q 5.0 ±0.03 0.2 26.4 4.1 Grooving Low cutting force type GCM N6002-GF D D D Q Q 6.0 ±0.03 0.2 26.4 4.5 Fig 2 2-RE RG GCM N3015-RG D D D D D Q 3.0 ±0.03 1.5 21.1 3.8 Cut-Off Profiling CW GCM N4020-RG D D D D D Q 4.0 ±0.03 2.0 26.4 4.0 5 2 Threading L GCM N5025-RG D D D D Q Q 5.0 ±0.03 2.5 27.2 4.1 S General purpose type GCM N6030-RG D D D D Q Q 6.0 ±0.03 3.0 27.5 4.5 Facing/Necking Fig 2 RN GCM N2010-RN Q Q D D Q Q 2.0 ±0.03 1.0 21.7 3.6 2-RE GCM N3015-RN D D D D Q Q 3.0 ±0.03 1.5 22.4 3.8 CW GCM N4020-RN D D D D Q Q 4.0 ±0.03 2.0 28.0 4.0 5 2 L S GCM N5025-RN D D D D Q Q 5.0 ±0.03 2.5 28.1 4.1 General purpose type GCM N6030-RN D D D D Q Q 6.0 ±0.03 3.0 28.1 4.5 For non-ferrous metals Fig 3 GA GCG N2002-GA Q Q Q Q Q D 2.0 ±0.025 0.2 21.1 3.6 4-RE GCG N3002-GA Q Q Q Q Q D 3.0 ±0.025 0.2 21.1 3.8 CW L GCG N4004-GA Q Q Q Q Q D 4.0 ±0.025 0.4 26.4 4.0 5 3 S GCG N5004-GA Q Q Q Q Q D 5.0 ±0.025 0.4 26.4 4.1 General purpose type GCG N6004-GA Q Q Q Q Q D 6.0 ±0.025 0.4 26.4 4.5 Use a combination of an insert and a holder with the same edge width CW. GNDIS type holders cannot be used. Recommended Cutting Conditions F21 F39

Каталог Sumitomo пластины с алмазными вставками Sumidia

Каталог Sumitomo пластины с алмазными вставками Sumidia Каталог Sumitomo микроинструмент

Каталог Sumitomo микроинструмент Общий каталог Sumitomo 2012

Общий каталог Sumitomo 2012 Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal Каталог Sumitomo пластины с кубическим нитридом бора Sumiboron

Каталог Sumitomo пластины с кубическим нитридом бора Sumiboron Общий каталог Sumitomo 2018 - 2019

Общий каталог Sumitomo 2018 - 2019