Каталог Sumitomo инструмент для обработки канавок - страница 3

Навигация

- F001

- F002

- F003

- F004

- F005

- F006

- F007

- F008

- F009

- F010

- F011

- F012

- F013

- F014

- F015

- F016

- F017

- F018

- F019

- F020

- F021

- F022

- F023

- F024

- F025

- F026

- F027

- F028

- F029

- F030

- F031

- F032

- F033

- F034

- F035

- F036

- F037

- F038

- F039

- F040

- F041

- F042

- F043

- F044

- F045

- F046

- F047

- F048

- F049

- F050

- F051

- F052

- F053

- F054

- F055

- F056

- F057

- F058

- F059

- F060

- F061

- F062

- F063

- F064

- F065

- F066

- F067

- F068

- F069

- F070

- F071

- F072

- F073

- F074

- F075

- F076

- F077

- F078

- F079

- F080

- F081

- F082

- F083

- F084

- F085

- F086

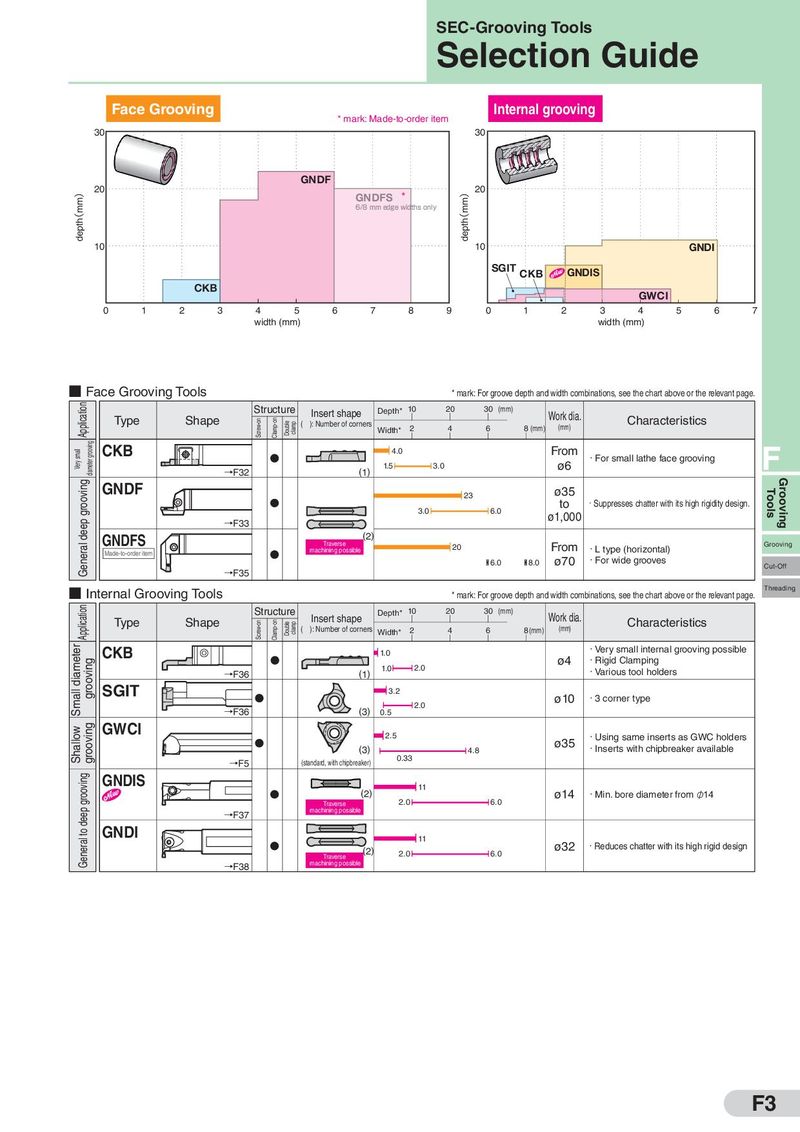

SEC-Grooving Tools Selection Guide Face Grooving * mark: Made-to-order item Internal grooving 30 30 GNDF depth(mm) 20 GNDFS * depth(mm) 20 6/8 mm edge widths only 10 10 GNDI SGIT CKB GNDIS CKB GWCI 0 1 2 3 4 5 6 7 8 9 0 1 2 3 4 5 6 7 width (mm) width (mm) ■ Face Grooving Tools * mark: For groove depth and width combinations, see the chart above or the relevant page. Application Structure Insert shape Depth* 10 20 30 (mm) Work dia. Type Shape Screw-on Clamp-on Double clamp ( ): Number of corners 2 4 6 8 (mm) (mm) Characteristics Width* Very small diameter grooving CKB 4.0 From ・For small lathe face grooving F →F32 (1) 1.5 3.0 ø6 grooving GNDF 23 ø35 Tools Grooving 3.0 6.0 to ・Suppresses chatter with its high rigidity design. deep →F33 ø1,000 GNDFS Traverse (2) General machining possible 20 From ・L type (horizontal) Grooving Made-to-order item ø70 ・For wide grooves 6.0 8.0 Cut-Off →F35 ■ Internal Grooving Tools * mark: For groove depth and width combinations, see the chart above or the relevant page. Threading Application Structure Insert shape Depth* 10 20 30 (mm) Work dia. Type Shape Screw-on Clamp-on Double clamp ( ): Number of corners 2 4 6 8(mm) (mm) Characteristics Width* Small diameter CKB 1.0 ・Very small internal grooving possible grooving 1.0 2.0 ø4 ・Rigid Clamping →F36 (1) ・Various tool holders SGIT 3.2 ø10 ・3 corner type →F36 (3) 2.0 0.5 Shallow grooving GWCI 2.5 ・Using same inserts as GWC holders (3) 4.8 ø35 ・Inserts with chipbreaker available →F5 (standard, with chipbreaker) 0.33 General to deep grooving GNDIS 11 (2) ø14 ・Min. bore diameter from φ14 Traverse 2.0 6.0 →F37 machining possible GNDI 11 (2) 2.0 6.0 ø32 ・Reduces chatter with its high rigid design Traverse →F38 machining possible F3

Каталог Sumitomo пластины с алмазными вставками Sumidia

Каталог Sumitomo пластины с алмазными вставками Sumidia Каталог Sumitomo микроинструмент

Каталог Sumitomo микроинструмент Общий каталог Sumitomo 2012

Общий каталог Sumitomo 2012 Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal Каталог Sumitomo пластины с кубическим нитридом бора Sumiboron

Каталог Sumitomo пластины с кубическим нитридом бора Sumiboron Общий каталог Sumitomo 2018 - 2019

Общий каталог Sumitomo 2018 - 2019