Каталог Sumitomo инструмент для обработки канавок - страница 11

Навигация

- F001

- F002

- F003

- F004

- F005

- F006

- F007

- F008

- F009

- F010

- F011

- F012

- F013

- F014

- F015

- F016

- F017

- F018

- F019

- F020

- F021

- F022

- F023

- F024

- F025

- F026

- F027

- F028

- F029

- F030

- F031

- F032

- F033

- F034

- F035

- F036

- F037

- F038

- F039

- F040

- F041

- F042

- F043

- F044

- F045

- F046

- F047

- F048

- F049

- F050

- F051

- F052

- F053

- F054

- F055

- F056

- F057

- F058

- F059

- F060

- F061

- F062

- F063

- F064

- F065

- F066

- F067

- F068

- F069

- F070

- F071

- F072

- F073

- F074

- F075

- F076

- F077

- F078

- F079

- F080

- F081

- F082

- F083

- F084

- F085

- F086

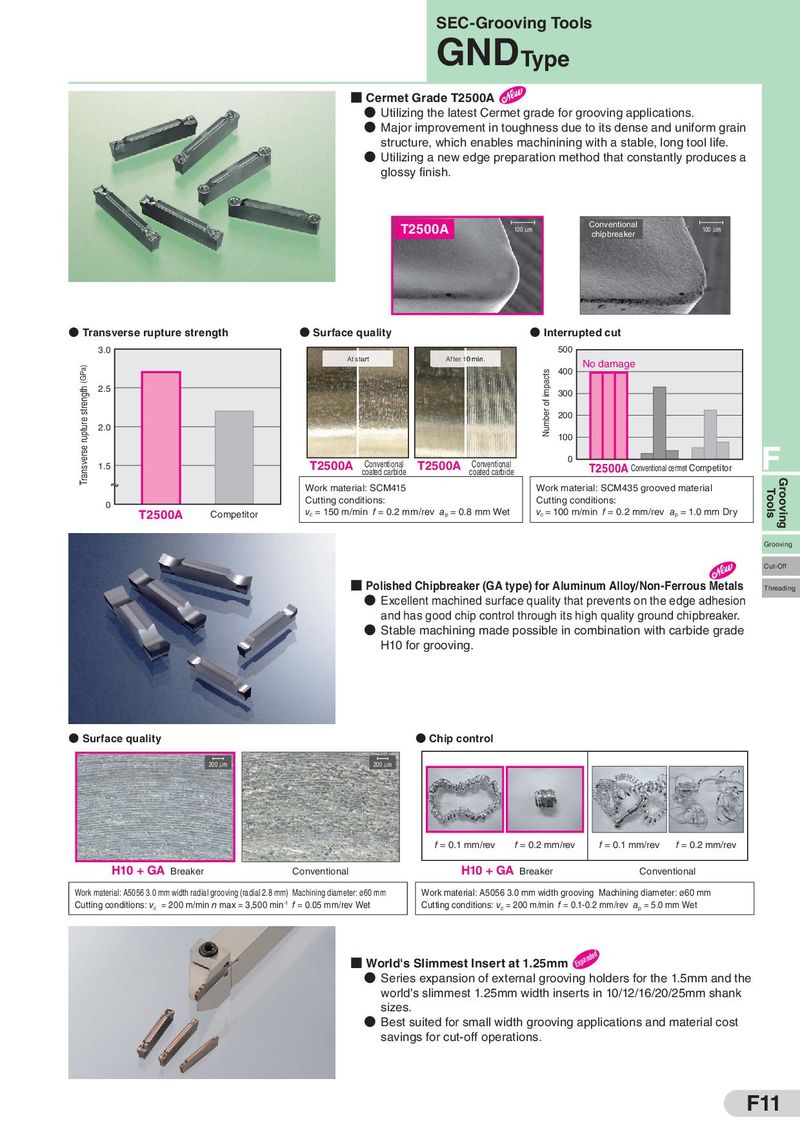

SEC-Grooving Tools GNDType ■ Cermet Grade T2500A ● Utilizing the latest Cermet grade for grooving applications. ● Major improvement in toughness due to its dense and uniform grain structure, which enables machinining with a stable, long tool life. ● Utilizing a new edge preparation method that constantly produces a glossy finish. T2500A 100 μm Conventional 100 μm chipbreaker ● Transverse rupture strength ● Surface quality ● Interrupted cut 3.0 500 At start After 10 min. No damage rupture strength (GPa) Number of impacts 400 2.5 300 200 2.0 100 Transverse 1.5 T2500A Conventional T2500A Conventional 0 T2500A Conventional cermet Competitor F coated carbide coated carbide Work material: SCM415 Work material: SCM435 grooved material Tools Grooving 0 Cutting conditions: Cutting conditions: T2500A Competitor vc = 150 m/min f = 0.2 mm/rev ap = 0.8 mm Wet vc = 100 m/min f = 0.2 mm/rev ap = 1.0 mm Dry Grooving Cut-Off ■ Polished Chipbreaker (GA type) for Aluminum Alloy/Non-Ferrous Metals Threading ● Excellent machined surface quality that prevents on the edge adhesion and has good chip control through its high quality ground chipbreaker. ● Stable machining made possible in combination with carbide grade H10 for grooving. ● Surface quality ● Chip control 200 μm 200 μm f = 0.1 mm/rev f = 0.2 mm/rev f = 0.1 mm/rev f = 0.2 mm/rev H10 + GA Breaker Conventional H10 + GA Breaker Conventional Work material: A5056 3.0 mm width radial grooving (radial 2.8 mm) Machining diameter: ø60 mm Work material: A5056 3.0 mm width grooving Machining diameter: ø60 mm Cutting conditions: vc = 200 m/min n max = 3,500 min-1 f = 0.05 mm/rev Wet Cutting conditions: vc = 200 m/min f = 0.1-0.2 mm/rev ap = 5.0 mm Wet ■ World's Slimmest Insert at 1.25mm Expanded ● Series expansion of external grooving holders for the 1.5mm and the world's slimmest 1.25mm width inserts in 10/12/16/20/25mm shank sizes. ● Best suited for small width grooving applications and material cost savings for cut-off operations. F11

Каталог Sumitomo пластины с алмазными вставками Sumidia

Каталог Sumitomo пластины с алмазными вставками Sumidia Каталог Sumitomo микроинструмент

Каталог Sumitomo микроинструмент Общий каталог Sumitomo 2012

Общий каталог Sumitomo 2012 Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal Каталог Sumitomo пластины с кубическим нитридом бора Sumiboron

Каталог Sumitomo пластины с кубическим нитридом бора Sumiboron Общий каталог Sumitomo 2018 - 2019

Общий каталог Sumitomo 2018 - 2019