Каталог Sumitomo инструмент для обработки канавок - страница 10

Навигация

- F001

- F002

- F003

- F004

- F005

- F006

- F007

- F008

- F009

- F010

- F011

- F012

- F013

- F014

- F015

- F016

- F017

- F018

- F019

- F020

- F021

- F022

- F023

- F024

- F025

- F026

- F027

- F028

- F029

- F030

- F031

- F032

- F033

- F034

- F035

- F036

- F037

- F038

- F039

- F040

- F041

- F042

- F043

- F044

- F045

- F046

- F047

- F048

- F049

- F050

- F051

- F052

- F053

- F054

- F055

- F056

- F057

- F058

- F059

- F060

- F061

- F062

- F063

- F064

- F065

- F066

- F067

- F068

- F069

- F070

- F071

- F072

- F073

- F074

- F075

- F076

- F077

- F078

- F079

- F080

- F081

- F082

- F083

- F084

- F085

- F086

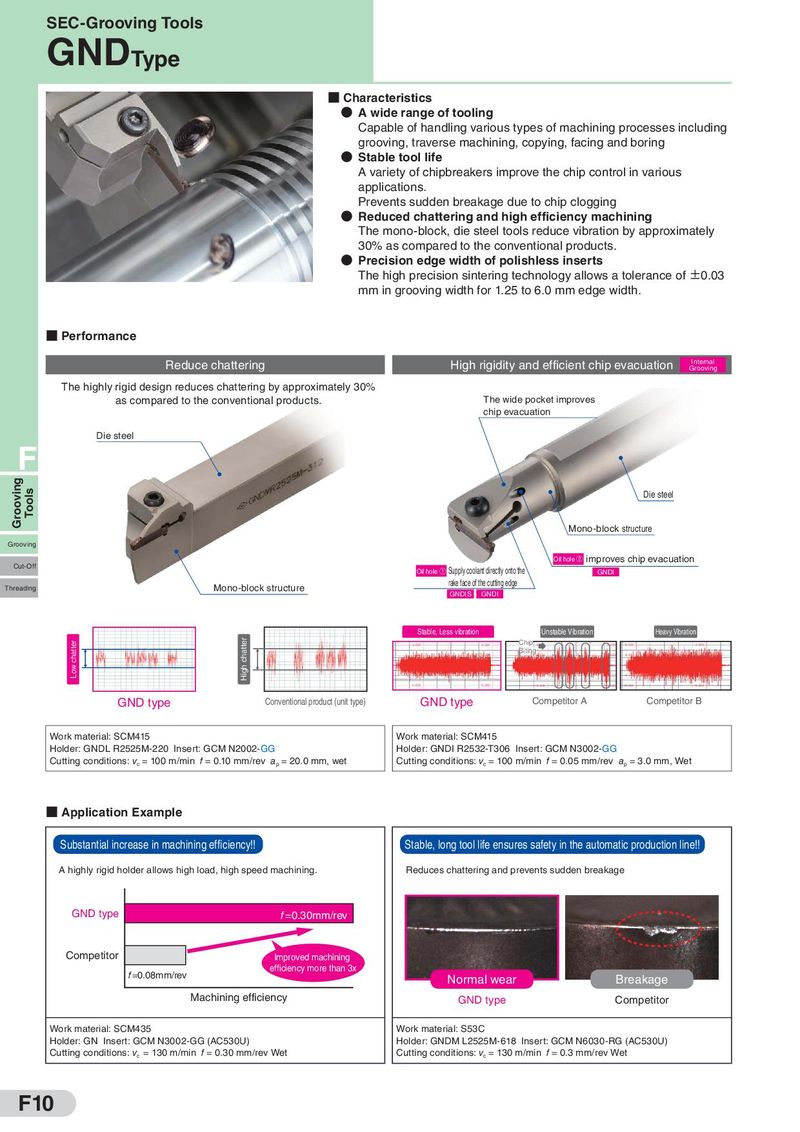

SEC-Grooving Tools GNDType ■ Characteristics ● A wide range of tooling Capable of handling various types of machining processes including grooving, traverse machining, copying, facing and boring ● Stable tool life A variety of chipbreakers improve the chip control in various applications. Prevents sudden breakage due to chip clogging ● Reduced chattering and high efficiency machining The mono-block, die steel tools reduce vibration by approximately 30% as compared to the conventional products. ● Precision edge width of polishless inserts The high precision sintering technology allows a tolerance of ±0.03 mm in grooving width for 1.25 to 6.0 mm edge width. ■ Performance Reduce chattering High rigidity and efficient chip evacuation Internal Grooving The highly rigid design reduces chattering by approximately 30% as compared to the conventional products. The wide pocket improves chip evacuation Die steel F Grooving Tools Die steel Mono-block structure Grooving Cut-Off Oil hole ② improves chip evacuation Oil hole ① Supply coolant directly onto the GNDI Threading Mono-block structure rake face of the cutting edge GNDIS GNDI Stable, Less vibration Unstable Vibration Heavy Vibration chatter chatter CChipp BBiittiinngg Low High GND type Conventional product (unit type) GND type Competitor A Competitor B Work material: SCM415 Work material: SCM415 Holder: GNDL R2525M-220 Insert: GCM N2002-GG Holder: GNDI R2532-T306 Insert: GCM N3002-GG Cutting conditions: vc = 100 m/min f = 0.10 mm/rev ap = 20.0 mm, wet Cutting conditions: vc = 100 m/min f = 0.05 mm/rev ap = 3.0 mm, Wet ■ Application Example Substantial increase in machining efficiency!! Stable, long tool life ensures safety in the automatic production line!! A highly rigid holder allows high load, high speed machining. Reduces chattering and prevents sudden breakage GND type f =0.30mm/rev Competitor Improved machining f =0.08mm/rev efficiency more than 3x Normal wear Breakage Machining efficiency GND type Competitor Work material: SCM435 Work material: S53C Holder: GN Insert: GCM N3002-GG (AC530U) Holder: GNDM L2525M-618 Insert: GCM N6030-RG (AC530U) Cutting conditions: vc = 130 m/min f = 0.30 mm/rev Wet Cutting conditions: vc = 130 m/min f = 0.3 mm/rev Wet F10

Каталог Sumitomo пластины с алмазными вставками Sumidia

Каталог Sumitomo пластины с алмазными вставками Sumidia Каталог Sumitomo микроинструмент

Каталог Sumitomo микроинструмент Общий каталог Sumitomo 2012

Общий каталог Sumitomo 2012 Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal Каталог Sumitomo пластины с кубическим нитридом бора Sumiboron

Каталог Sumitomo пластины с кубическим нитридом бора Sumiboron Общий каталог Sumitomo 2018 - 2019

Общий каталог Sumitomo 2018 - 2019