Каталог Sumitomo инструмент для обработки канавок - страница 6

Навигация

- F001

- F002

- F003

- F004

- F005

- F006

- F007

- F008

- F009

- F010

- F011

- F012

- F013

- F014

- F015

- F016

- F017

- F018

- F019

- F020

- F021

- F022

- F023

- F024

- F025

- F026

- F027

- F028

- F029

- F030

- F031

- F032

- F033

- F034

- F035

- F036

- F037

- F038

- F039

- F040

- F041

- F042

- F043

- F044

- F045

- F046

- F047

- F048

- F049

- F050

- F051

- F052

- F053

- F054

- F055

- F056

- F057

- F058

- F059

- F060

- F061

- F062

- F063

- F064

- F065

- F066

- F067

- F068

- F069

- F070

- F071

- F072

- F073

- F074

- F075

- F076

- F077

- F078

- F079

- F080

- F081

- F082

- F083

- F084

- F085

- F086

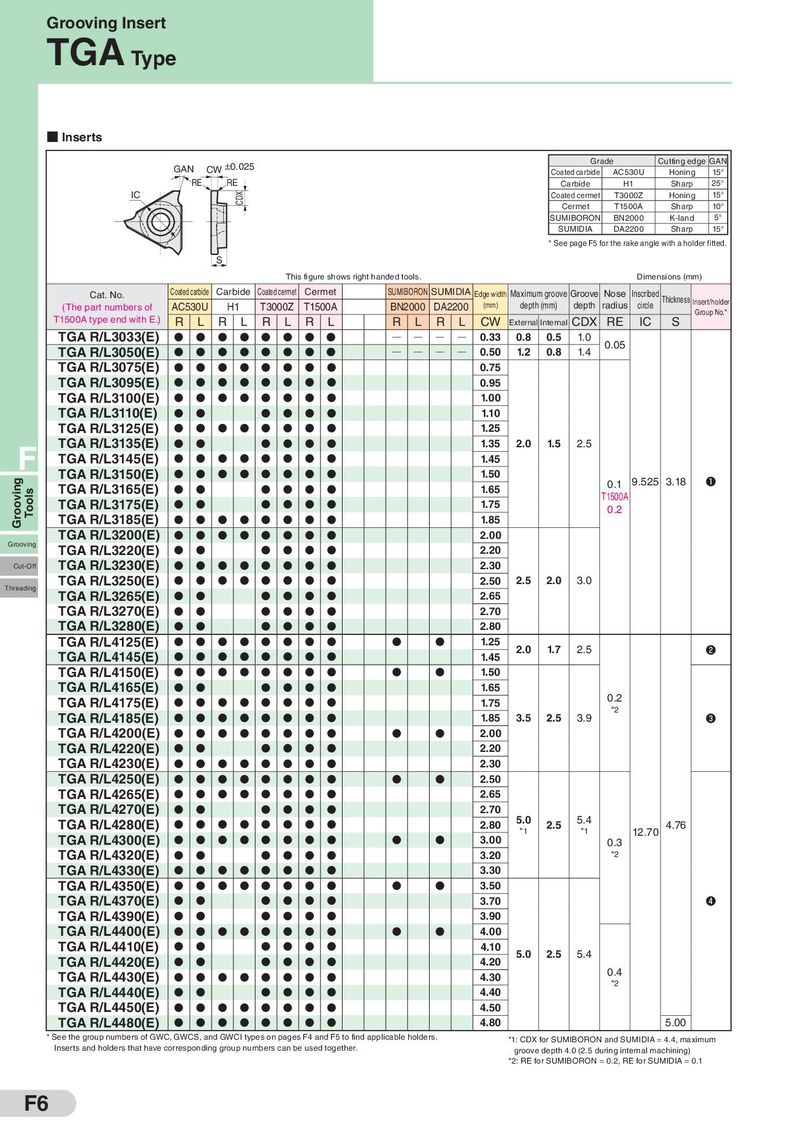

Grooving Insert TGA Type ■ Inserts GAN 0.025 Grade Cutting edge GAN CW Coated carbide AC530U Honing 15° RE RE Carbide H1 Sharp 25° IC CDX Coated cermet T3000Z Honing 15° Cermet T1500A Sharp 10° SUMIBORON BN2000 K-land 5° SUMIDIA DA2200 Sharp 15° * See page F5 for the rake angle with a holder fitted. S This figure shows right handed tools. Dimensions (mm) Cat. No. Coated carbide Carbide Coated cermet Cermet SUMIBORON SUMIDIA Edge width Maximum groove Groove Nose Inscribed Thickness (The part numbers of AC530U H1 T3000Z T1500A BN2000 DA2200 (mm) depth (mm) depth radius circle Insert/holder T1500A type end with E.) Group No.* R L R L R L R L R L R L CW External Internal CDX RE IC S TGA R/L3033(E) D D D D D D D D Q Q Q Q 0.33 0.8 0.5 1.0 0.05 TGA R/L3050(E) D D D D D D D D Q Q Q Q 0.50 1.2 0.8 1.4 TGA R/L3075(E) D D D D D D D D 0.75 TGA R/L3095(E) D D D D D D D D 0.95 TGA R/L3100(E) D D D D D D D D 1.00 TGA R/L3110(E) D D D D D D 1.10 TGA R/L3125(E) D D D D D D D D 1.25 F TGA R/L3135(E) D D D D D D 1.35 2.0 1.5 2.5 TGA R/L3145(E) D D D D D D D D 1.45 Grooving TGA R/L3150(E) D D D D D D D D 1.50 9.525 3.18 ❶ Tools TGA R/L3165(E) D D D D D D 1.65 0.1 TGA R/L3175(E) D D D D D D 1.75 T1500A TGA R/L3185(E) 0.2 D D D D D D D D 1.85 TGA R/L3200(E) D D D D D D D D 2.00 Grooving TGA R/L3220(E) D D D D D D 2.20 Cut-Off TGA R/L3230(E) D D D D D D D D 2.30 Threading TGA R/L3250(E) D D D D D D D D 2.50 2.5 2.0 3.0 TGA R/L3265(E) D D D D D D 2.65 TGA R/L3270(E) D D D D D D 2.70 TGA R/L3280(E) D D D D D D 2.80 TGA R/L4125(E) D D D D D D D D D D 1.25 2.0 1.7 2.5 ❷ TGA R/L4145(E) D D D D D D D D 1.45 TGA R/L4150(E) D D D D D D D D D D 1.50 TGA R/L4165(E) D D D D D D 1.65 TGA R/L4175(E) D D D D D D D D 1.75 0.2 TGA R/L4185(E) *2 D D D D D D D D 1.85 3.5 2.5 3.9 ❸ TGA R/L4200(E) D D D D D D D D D D 2.00 TGA R/L4220(E) D D D D D D 2.20 TGA R/L4230(E) D D D D D D D D 2.30 TGA R/L4250(E) D D D D D D D D D D 2.50 TGA R/L4265(E) D D D D D D D D 2.65 TGA R/L4270(E) D D D D D D 2.70 TGA R/L4280(E) D D D D D D D D 2.80 5.0 2.5 5.4 4.76 TGA R/L4300(E) *1 *1 12.70 D D D D D D D D D D 3.00 0.3 TGA R/L4320(E) D D D D D D 3.20 *2 TGA R/L4330(E) D D D D D D D D 3.30 TGA R/L4350(E) D D D D D D D D D D 3.50 TGA R/L4370(E) D D D D D D 3.70 ❹ TGA R/L4390(E) D D D D D D 3.90 TGA R/L4400(E) D D D D D D D D D D 4.00 TGA R/L4410(E) D D D D D D 4.10 5.0 2.5 5.4 TGA R/L4420(E) D D D D D D 4.20 TGA R/L4430(E) D D D D D D D D 4.30 0.4 TGA R/L4440(E) *2 D D D D D D 4.40 TGA R/L4450(E) D D D D D D D D 4.50 TGA R/L4480(E) D D D D D D D D 4.80 5.00 * See the group numbers of GWC, GWCS, and GWCI types on pages F4 and F5 to find applicable holders. *1: CDX for SUMIBORON and SUMIDIA = 4.4, maximum Inserts and holders that have corresponding group numbers can be used together. groove depth 4.0 (2.5 during internal machining) *2: RE for SUMIBORON = 0.2, RE for SUMIDIA = 0.1 F6

Каталог Sumitomo пластины с алмазными вставками Sumidia

Каталог Sumitomo пластины с алмазными вставками Sumidia Каталог Sumitomo микроинструмент

Каталог Sumitomo микроинструмент Общий каталог Sumitomo 2012

Общий каталог Sumitomo 2012 Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal Каталог Sumitomo пластины с кубическим нитридом бора Sumiboron

Каталог Sumitomo пластины с кубическим нитридом бора Sumiboron Общий каталог Sumitomo 2018 - 2019

Общий каталог Sumitomo 2018 - 2019