Каталог Sumitomo инструмент для обработки канавок - страница 41

Навигация

- F001

- F002

- F003

- F004

- F005

- F006

- F007

- F008

- F009

- F010

- F011

- F012

- F013

- F014

- F015

- F016

- F017

- F018

- F019

- F020

- F021

- F022

- F023

- F024

- F025

- F026

- F027

- F028

- F029

- F030

- F031

- F032

- F033

- F034

- F035

- F036

- F037

- F038

- F039

- F040

- F041

- F042

- F043

- F044

- F045

- F046

- F047

- F048

- F049

- F050

- F051

- F052

- F053

- F054

- F055

- F056

- F057

- F058

- F059

- F060

- F061

- F062

- F063

- F064

- F065

- F066

- F067

- F068

- F069

- F070

- F071

- F072

- F073

- F074

- F075

- F076

- F077

- F078

- F079

- F080

- F081

- F082

- F083

- F084

- F085

- F086

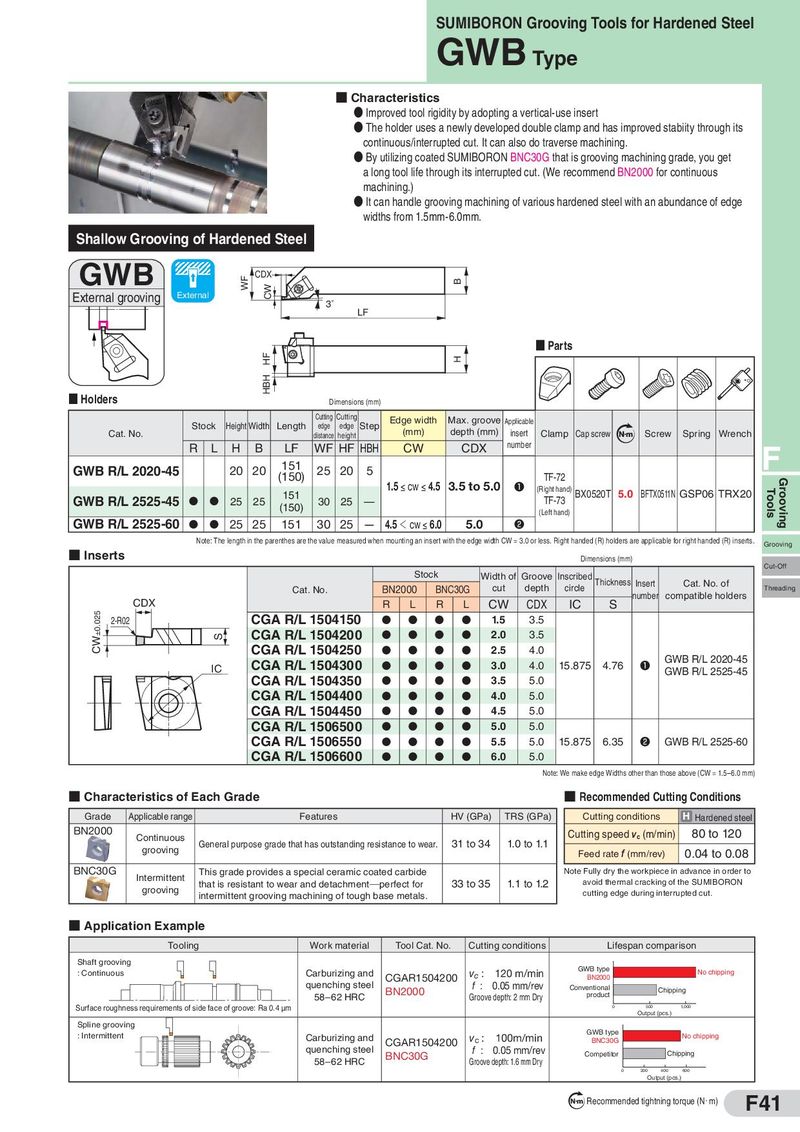

SUMIBORON Grooving Tools for Hardened Steel GWB Type ■ Characteristics ● Improved tool rigidity by adopting a vertical-use insert ● The holder uses a newly developed double clamp and has improved stabiity through its continuous/interrupted cut. It can also do traverse machining. ● By utilizing coated SUMIBORON BNC30G that is grooving machining grade, you get a long tool life through its interrupted cut. (We recommend BN2000 for continuous machining.) ● It can handle grooving machining of various hardened steel with an abundance of edge widths from 1.5mm-6.0mm. Shallow Grooving of Hardened Steel GWB WF CDX B External grooving External CW 3˚ LF ■ Parts HF H HBH ■ Holders Dimensions (mm) Cutting Cutting Edge width Max. groove Applicable Cat. No. Stock Height Width Length edge edge Step (mm) depth (mm) insert Clamp Cap screw Screw Spring Wrench distance height Nm R L H B LF WF HF HBH CW CDX number F GWB R/L 2020-45 20 20 151 25 20 5 (150) 1.5 ≤ cw ≤ 4.5 3.5 to 5.0 TF-72 Grooving 151 ❶ (Right hand) BX0520T 5.0 BFTX0511N GSP06 TRX20 Tools GWB R/L 2525-45 D D 25 25 (150) 30 25 — TF-73 (Left hand) GWB R/L 2525-60 D D 25 25 151 30 25 — 4.5 < cw ≤ 6.0 5.0 ❷ Note: The length in the parenthes are the value measured when mounting an insert with the edge width CW = 3.0 or less. Right handed (R) holders are applicable for right handed (R) inserts. Grooving ■ Inserts Dimensions (mm) Cut-Off Stock Width of Groove Inscribed Thickness Cat. No. BN2000 BNC30G cut depth circle Insert Cat. No. of Threading CDX R L R L CW CDX IC S number compatible holders CW±0.025 2-R02 CGA R/L 1504150 D D D D 1.5 3.5 S CGA R/L 1504200 D D D D 2.0 3.5 CGA R/L 1504250 D D D D 2.5 4.0 GWB R/L 2020-45 IC CGA R/L 1504300 D D D D 3.0 4.0 15.875 4.76 ❶ GWB R/L 2525-45 CGA R/L 1504350 D D D D 3.5 5.0 CGA R/L 1504400 D D D D 4.0 5.0 CGA R/L 1504450 D D D D 4.5 5.0 CGA R/L 1506500 D D D D 5.0 5.0 CGA R/L 1506550 D D D D 5.5 5.0 15.875 6.35 ❷ GWB R/L 2525-60 CGA R/L 1506600 D D D D 6.0 5.0 Note: We make edge Widths other than those above (CW = 1.5–6.0 mm) ■ Characteristics of Each Grade ■ Recommended Cutting Conditions Grade Applicable range Features HV (GPa) TRS (GPa) Cutting conditions H Hardened steel BN2000 Continuous Cutting speed vc (m/min) 80 to 120 grooving General purpose grade that has outstanding resistance to wear. 31 to 34 1.0 to 1.1 0.04 to 0.08 Feed rate f (mm/rev) BNC30G Intermittent This grade provides a special ceramic coated carbide Note Fully dry the workpiece in advance in order to grooving that is resistant to wear and detachment̶perfect for 33 to 35 1.1 to 1.2 avoid thermal cracking of the SUMIBORON intermittent grooving machining of tough base metals. cutting edge during interrupted cut. ■ Application Example Tooling Work material Tool Cat. No. Cutting conditions Lifespan comparison Shaft grooving GWB type : Continuous Carburizing and CGAR1504200 vc : 120 m/min BN2000 No chipping quenching steel BN2000 f: 0.05 mm/rev Conventional Chipping 58–62 HRC Groove depth: 2 mm Dry product Surface roughness requirements of side face of groove: Ra 0.4 μm 0 500 1,000 Output (pcs.) Spline grooving : Intermittent Carburizing and vc : 100m/min GWB type No chipping CGAR1504200 BNC30G quenching steel BNC30G f: 0.05 mm/rev Competitor Chipping 58–62 HRC Groove depth: 1.6 mm Dry 0 200 400 600 Output (pcs.) N m Recommended tightning torque (N・m) F41

Каталог Sumitomo пластины с алмазными вставками Sumidia

Каталог Sumitomo пластины с алмазными вставками Sumidia Каталог Sumitomo микроинструмент

Каталог Sumitomo микроинструмент Общий каталог Sumitomo 2012

Общий каталог Sumitomo 2012 Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal Каталог Sumitomo пластины с кубическим нитридом бора Sumiboron

Каталог Sumitomo пластины с кубическим нитридом бора Sumiboron Общий каталог Sumitomo 2018 - 2019

Общий каталог Sumitomo 2018 - 2019