Общий каталог ZCC-CT 2019 - страница 695

Навигация

- Title page

- Summary

- Turning

- Overview

- Insert overview negative inserts

- Insert overview positive inserts

- ISO code – general turning inserts

- ISO code – PCBN & PCD inserts

- Insert overview CBN & PKD

- Insert overview Ceramic

- Overview holder external

- Overview boring bars

- Explanation chipbreaker -ADF -AHF

- Explanation chipbreaker-ZM

- Explanation chipbreaker -NGF -SNR

- Grade explanation YBG101

- Grade explanation YB9320

- Grade explanationYB7315

- Simply Coloured

- Chip breaker overview negativ inserts

- Application fields of chip breakers

- Finishing

- Wiper

- Medium machining

- Roughing

- Chip breaker overview positiv inserts

- Application fields of chip breakers

- Fine-finishing

- Finishing

- Medium machining

- Roughing

- Aluminium machining

- Grade overview CVD

- Application field of grades CVD

- Grade overview PVD

- Application field of grades PVD

- Grade explanation Ceramic

- Grade explanation uncoated cermented cabidel

- Grade explanation CBN

- Grade explanation PKD

- Grade explanation Cermet

- Application felds of grade

- Conversion table metric/imperial

- Negative inserts

- CN**

- DN**

- SN**

- TN**

- VN**

- WN**

- RN**

- KN**

- Railway wheel machining

- Positiv inserts

- CC**

- CP**

- DC**

- DP**

- RC**

- SC**

- SP**

- TB**

- TC**

- TP**

- VC**

- VB**

- WC**

- CBN / PKD

- Negativ inserts

- CN**

- DN**

- SN**

- TN**

- VN**

- WN**

- Positiv inserts

- CC**

- DC**

- TC**

- VB**

- VC**

- Solide CBN

- CN**

- SN**

- WN**

- RN**

- PKD

- CC**

- DC**

- TC**

- VB**

- VC**

- Ceramic

- CN*

- DN**

- SN**

- TN**

- RN**

- WN**

- External tool holders overview

- ISO code – external tool holders

- D- Holder

- DCLNR/L Kr: 95°

- DDJNR/L Kr: 93°

- DSBNR/L Kr: 75°

- DTGNR/L Kr: 91°

- DVVNN Kr: 72°30'

- DVJNR/L Kr: 93°

- DWLNR/L Kr: 95°

- P- Holder

- PCBNR/L Kr: 75°

- PCLNR/L Kr: 95

- PDJNR/L Kr: 93°

- PDNNR/L Kr: 63°

- PSBNR/L Kr: 75°

- PSDNN Kr: 45°

- PSKNR/L Kr: 75°

- PSSNR/L Kr: 45°

- PTFNR/L Kr: 91°

- PTTNR/L Kr: 60°

- PTGNR/L Kr: 90°

- PWLNR/L Kr: 95°

- M- Halter

- MCBNR/L Kr: 75°

- MCLNR/L Kr: 95°

- MDJNR/L Kr: 93

- MDPNN Kr: 62°30'

- MSBNR/L Kr: 75

- MSRNR/L Kr: 75

- MSKNR/L Kr: 75°

- MSDNN Kr: 45°

- MTGNR/L Kr: 90°

- MTJNR/L Kr: 93°

- MTFNR/L Kr: 91°

- MVVNN Kr: 72°30'

- MVJNR/L Kr: 93°

- MWLNR/L Kr: 95°

- MRDNN

- MRGNR/L

- S- Holder

- SCACR/L Kr: 90°

- SCLCR/L Kr: 95°

- SDACR/L Kr: 90°

- SDJCR/L Kr: 93°

- SDNCN Kr: 62°30'

- SVJBR/L Kr: 93°

- SVABR/L Kr: 90°

- SVVBN Kr: 72°30'

- SVVCN Kr: 72°30'

- SVJCR/L Kr: 93°

- SSBCR/L Kr: 75°

- SSDCN Kr: 45°

- SSKCR/L Kr: 75°

- SSSCR/L Kr: 45°

- STACR/L Kr: 90°

- STFCR/L Kr: 91°

- STGCR/L Kr: 91°

- STTCR/L Kr: 60°

- SWACR/L Kr: 90°

- SRDCN

- SRGCR/L

- C- Holder

- CKJNR/L Kr: 93°

- CCLNR/L Kr: 95°

- CTJNR/L Kr: 93°

- CDJNR/L Kr: 93°

- CTUNR/L Kr: 93

- CSKNR/L Kr: 75°

- CSRNR/L Kr: 75°

- CRDNN

- CSDNN Kr: 45°

- J- Holder

- JDJNR/L Kr: 93°

- JSDNN Kr: 45°

- External tool holders – Swiss turning

- ISO code

- SCACR/L-SC Kr: 90°

- SCLCR/L-SC Kr: 95°

- SDACR/L-SC Kr: 90°

- SDHCR/L-SC Kr: 107°30'

- SDJCR/L-SC Kr: 93°

- SDNCN-SC Kr: 62°30'

- SVACR/L-SC Kr: 90°

- SVJCR/L-SC Kr: 93°

- Boring bars overview

- ISO code – boring bars

- P- boring bar

- PCLNR/L Kr: 95°

- PDSNR/L Kr: 62°30

- PDUNR/L Kr: 93°

- PSKNR/L Kr: 75°

- PTFNR/L Kr: 90°

- PWLNR/L Kr: 95°

- S- boring bar

- SCLCR/L Kr: 95°

- SDQCR/L Kr: 107°30'

- SDUCR/L Kr: 93°

- SDZCR/L Kr: 85°

- SSKCR/L Kr: 75°

- STFCR/L Kr: 91°

- SVQCR/L Kr: 107°30'

- SVUCR/L Kr: 93°

- SVQBR/L Kr: 107°30

- SVUBR/L Kr: 93°

- SCLPR/L Kr: 95°

- SDQPR/L Kr: 107°30'

- SDUPR/L Kr: 93°

- STUPR/L Kr: 93°

- SCFCR/L Kr: 90°

- SCLCR/L Kr: 95°

- Anti Vibration Boring Bar

- SCLCR/L Kr: 95°

- SCLCR/L Kr: 95°

- SDQPR/L Kr: 107°30'

- SDQCR/L Kr: 107°30'

- SDUPR/L Kr: 93°

- SDUCR/L Kr: 93°

- STUPR/L Kr: 93°

- STFCR/L Kr: 90°

- STFPR/L Kr: 90°

- SVQCR/L Kr: 107°30'

- SVUCR/L Kr: 93°

- Parting & grooving

- Overview

- Product overview

- System overview

- Chip breaker overview

- Grade overview

- System code – inserts

- ZT*D*MM

- ZP*D*MG

- ZP*S**MG

- ZP*D**MG*L/R

- ZT*D**MG

- ZT*S**MG

- ZT*D**EG grinded

- ZR*D**MG

- ZR*F**EG

- ZIMF**NM

- ZIGQ*NM

- ZR*D**LH

- ZILD**LC

- Parting & grooving holders

- System code – tool holders

- External tool holders

- Boring bars

- Blade & Clamping block

- Boring bars

- C**-Q*DR/L (from 2mm)

- C40X-Q*DR/L

- Parting & grooving tool holder (external)

- QE**R/L

- QE**SN

- QECD**R/L

- QX*D**R/L

- QE**SR/L

- QE*S**N

- QZS** (Monoblock)

- Parting & grooving tool holder (axial)

- QF**R/L

- QF**RR/LL

- QF**SRR/LL

- QF**DR/L

- QFHSDR/L

- QF**R/L

- QC - Parting & grooving system

- System code - inserts

- QC inserts

- System code - tool holder

- Grooving (external)

- Grooving (Internal)

- Threading

- Grade overview

- System code – inserts

- System overview (Sandvik compatibel R166.)

- GM - ISO metric coarse thread 60°

- Partial profile 60°

- Partial profile 55°

- Whitworth

- Unified conventional thread

- BSPT Whitworth taper pipe thread

- NPT American taper pipe thread

- NPTF dryseal American taper pipe thread

- R knuckle thread 30°

- MJ thread for aerospace

- UNJ unified screw thread

- TR metrical ISO trapezoidal thread

- ACME American national thread

- STUB-ACME thread

- API 60° thread

- API round thread

- API American buttress thread

- System overview (ThinType)

- ISO metric coarse thread 60°

- Partial profile 60

- Partial profile 55°

- Whitworth

- UN unified conventional thread

- BSPT Whitworth taper pipe thread

- NPT American taper pipe thread

- System code – tool holders (Sandvik compatibel R166.)

- Threading tool holder (Sandvik compatible R166.)

- Threading tool holder ( ISO - ThinType)

- Cutting datas

- Recommended cutting data inserts, negativ

- Recommended cutting data inserts, positiv

- Recommended cutting data inserts, Parting & grooving

- Recommended cutting data inserts, Threading inserts

- Technical informations

- Milling

- Indexable Milling

- Overview

- Produkt overview inserts

- System overview

- Facemilling

- Square shoulder milling

- Profile milling

- Slot milling

- High feed milling

- Bore milling

- T-slot milling

- Helical milling

- Champfer milling

- Indexable heads - QCH

- Chip breakers overview

- Grade overview

- System code – milling bodies

- ISO code – inserts

- System code – slot milling

- Face milling

- FMA01 Kr: 45°

- FMA02 Kr: 45°

- FMA03 Kr: 45°

- FMA04 Kr: 45° screws clamping

- FMA04 Kr: 45° wedge clamping

- FMA07 Kr: 45°

- FMA11 Kr: 45°

- FMA12 Kr: 45°

- FMD02 Kr: 67°

- FMD02 Kr: 55° (alt)

- FMD03 Kr: 60°

- FME02 Kr: 75°

- FME03 Kr: 75°

- FME04 Kr: 75°

- FMP01 Kr: 90°

- FMP02 Kr: 90°

- FMP03 Kr: 89°

- FMP12 Kr: 90°

- FMR01 round insert

- FMR02 round insert

- FMR03 round insert thick inserts

- FMR03 round insert thin inserts

- FMR04 round insert thick inserts

- FMR04 round insert thin inserts

- Square sholder milling

- EMP01

- EMP02

- EMP03

- EMP04

- EMP05

- EMP09

- EMP13

- Profile milling

- BMR01

- BMR02

- BMR03

- BMR04

- Slot milling

- SMP01

- SMP03

- SMP05

- High feed milling

- XMR01 SDMT

- XMR01 WPGT

- Bore milling

- XMP01

- T-slot milling

- TMP01

- Helical milling

- HMP01

- HMP01 EC

- Chamfer milling

- CMZ01 Kr: 30°

- CMA01 Kr: 45°

- CMD01 Kr: 60°

- Indexable heads

- QCH - XPHT

- QCH - SDMT

- QCH - WPGT

- QCH - APKT

- QCH - RD Dicke Platte

- QCH - RD Dünne Platte

- QCH - ZOHX

- Milling inserts without bodys

- HNGX

- LNE

- LNCX

- SNKN

- SPAN / SPCN

- SPMR

- SPMT

- SPGN / SPUN

- TPAN / TPCN

- TPKN

- TPMR / TPUN

- Guide for recommended cutting data – indexable milling

- Recommended cutting data

- Group 1 (FMA07/11/12, FMD02, EMP09/13)

- Group 2 (FMA01/02/03/04, FME01/02, EMP01/02/03/04)

- Group 3 (FMR01/02/03/04)

- Group 4 (BMR01/02/03/04, TMP01,CMZ01,CMA01,CMD01)

- Group 5 (SMP01/03/05)

- Group 6 (FMD03, FME04, FMP03, HMP01)

- Group 7 (XMR01, XMP01)

- Recommend feed rate

- Group 1 / 2

- Group 3

- Group 4 / 5

- Group 6 / 7

- Solid carbide milling

- Overview

- Grade overview

- System code – DIN-ISO series

- System code – JIS series

- GM - series

- 2 Flute End mill

- 5501R302GM

- 5601R302GM

- 5502R302GM

- 5602R302GM

- GM-2E

- GM-2EL

- GM-2EX

- GM-2EFP

- GM-2F

- GM-2FL

- GM-2EP

- GM-2ES

- 3 Flute End mill

- GM-3E

- GM-3EL

- 5501R303GM

- 5601R303GM

- 5502R303GM

- 5602R303GM

- 5502R453GM

- 5602R453GM

- 4 Flute End mill

- GM-4F-G

- GM-4EL-G

- GM-4FL-G

- GM-4EX-G

- GM-4E

- GM-4E-G

- GM-4EL

- GM-4EFP

- 5501R304GF

- 5601R304GF

- 5502R304GF

- 5602R304GF

- 5508R454GM

- 5602R454GM

- Multiflute End mill

- 5589R45MGFR02

- GM-6E

- GM-6EL

- 2 Flute Ball nose cutter

- 5565R302GF

- 5665R202GM

- 5566R302GF

- GM-2B

- GM-2BL

- GM-2BFP

- GM-2BS

- GM-2BP

- 4 Flute Ball nose cutter

- GM-4B

- GM-4BL

- 2 Flute Torus mill

- GM-2R

- 4 Flute Torus mill

- GM-4R

- GM-4RL

- Ripper

- 5602R303GR

- 5602R304GR

- 5602R305GR

- GM-4W

- PM - series

- 2 Flute End mill

- PM-2E

- PM-2EL

- 4 Flute End mill

- PM-4E-G

- PM-4EL-G

- PM-4EX-G

- PM-4E

- PM-4EL

- 6 Flute End mill

- PM-6E

- PM-6EL

- 2 Flute Ball nose cutter

- PM-2B

- PM-2BL

- PM-2BFP

- PM-2BC

- 4 Flute Ball nose cutter

- PM-4B

- PM-4BL

- 2 Flute Torus mill

- PM-2R

- 4 Flute Torus mill

- PM-4H

- PM-4HL

- PM-4R

- PM-4RL

- HM - series

- 2 Flute End mill

- HM-2E

- HM-2EFP

- HM-2EP

- HM-2ES

- 4 Flute End mill

- HM-4E

- HM-4EL

- HM-4EFP

- Multiflute End mill

- 5502R55MHH

- HM-6E

- HM-6EL

- 2 Flute Ball nose cutter

- HM-2B

- HM-2BL

- HM-2BFP

- HM-2BS

- HM-2BP

- 4 Flute Ball nose cutter

- HM-4B

- HM-4BL

- 4 Flute Torus mill

- HM-4R

- HM-4RF

- HM-4RP

- NM - series

- 2 Flute End mill

- 5502R402NM

- NM-2E

- NM-2EP

- 4 Flute End mill

- NM-4E

- 2 Flute Ball nose cutter

- NM-2B

- NM-2BP

- AL - series

- 2 Flute End mill

- AL-2E

- AL-2EL

- ALG-2E

- 3 Flute End mill

- AL-3E

- AL-3EL

- ALG-3E

- ALG-3E-W

- ALP-3E

- ALP-3E-W

- 4 Flute End mill

- ALP-4E

- ALP-4E-W

- Ripper

- AL-3W

- 2 Flute Ball nose cutter

- 5565R302NH

- 5566R302NH

- AL-2B

- 2 Flute Torus mill

- AL-2R-AIR

- AL-2RL-AIR

- ALG-2R

- ALG-2R-W

- 3 Flute Torus mill

- AL-3R-AIR

- AL-3RL-AIR

- HPC / HSC

- DIN - series

- End mill

- 5501R38414GM

- 5502R38414GM

- 5601R38414GM

- 5602R38414GM

- Torus mill

- 5502R38414GM-R

- 5602R38414GM-R

- UM - series

- End mill

- UM-4E

- UM-4E-W

- UM-4EL

- UM-4EL-W

- UM-4ELP-W

- UM-4EFP

- Torus mill

- UM-4R

- UM-4RL

- UM-4RFP

- VSM - series

- Endmill

- VSM-4E

- VSM-4E-C

- Torus Mill

- VSM-4R

- Deburing cutter

- 5501/5601R60*FM - 60°

- 5501/5601R90*FM - 90°

- 5601R90*FM-R - Radius

- Recommended cutting data solid carbide milling

- Guide for recommended cutting data

- Recommended cutting data GM Serie

- Recommended cutting data HM Serie

- Recommended cutting data NMSerie

- Recommended cutting data AL Serie

- Recommended cutting data PM Serie

- Recommended cutting data HPC / UM / VSM Serie

- Recommended cutting data FM Serie Deburing cutter

- Solid carbide milling group 1 / 2 / 3 / 4

- Solid carbide milling group 5 / 6 / 7 / 8

- Solid carbide milling group 9 / 10 / 11

- Technical informations milling

- Trouble shooting – milling

- General formulas

- Plunging and circular milling with insert APKT

- Plunging and circular milling with insert WPGT or SDMT

- Machining strategy – HPC/UM (HSC) milling cutters

- Form nonstandard order

- Drilling

- Indexable drills

- Products Overview

- Chip breaker overview

- Grade overview

- System code – drilling bodies

- ZTD - series

- ZTD02

- ZTD03

- ZTD04

- ZTD05

- ZD - series

- ZD03

- ISO-Code – inserts

- Insers indexable drills

- Recommended cutting data Indexable drills

- Solid carbide drills

- Product overview

- Grade overview

- System code – solid carbide drills

- SU - series

- SU(K) drill 3xD shank HA

- SU(K) drill 5xD shank HA

- SU(K) drill 8xD shank HA

- SU(K) drill 3xD shank HB

- SU(K) drill 5xD shank HB

- SU(K) drill 3xD shank HE

- SU(K) drill 5xD shank HE

- SU 3xD Step drill

- SL - series

- SL(K) drill 10xD

- SL(K) drill 12xD

- SL(K) drill 15xD

- SL(K) drill 20xD

- SL(K) drill 30xD

- SP drill 3xD (Pilot)

- ST - series

- ST drill 3xD Shank HA

- ST drill 5xD Shank HA

- ST drill 5xD Shank HB

- SH - series

- SH drill 3xD Shank HA

- SC - series

- SC drill 3xD

- SC drill 5xD

- PA - series

- PA drill 3xD

- PC - series

- PC drill 5xD

- PC drill 15xD

- NC tapping device

- SC drill – NC tapping device 90°

- SC drill – NC tapping device 120°

- Recommended cutting data – solid carbide drilling

- Recommended cutting data – solid carbide drilling

- Recommended cutting data

- Recommended feed rate

- Solid carbide reamers

- Product overview

- Grade overview

- System code – solid carbide reamers

- 3101H7 Reamer, right-hand twist

- 3102H7 Reamer, straight flute

- 3112H7 Reamer, straight flute

- 3103H7 Reamer, left-hand twist

- Recommended cutting data – Solid carbide reamers

- Recommended cutting data – Solid carbide reamers

- Recommended cutting data

- Recommended feed rate

- Solid carbide threading tools

- Product overview

- Grade overview

- System code – solid carbide threading tools

- 4122A Thread formers

- 4222A Thread formers

- 4122M Thread formers

- 4222M Thread formers

- 4201C Tap, right-hand twist

- 4202C Tap, straight flute

- 4201A Tap, right-hand twist

- 4202A Tap, straight flute

- 4111 Thread milling cutter, coated

- Recommended cutting data – Solid carbide threading tool

- Guide for recommended cutting data

- Recommended cutting data

- Recommended feed rate

- Technical information

- Form nonstandard order

- Technical information

- Comparison table materials

- Comparison table hardness and tensile strength

- Conversion table chip breakers – turning

- Conversion table grades – turning

- Conversion table grades – milling

- Examples of materials for machining groups

- Form test protocol

- Torque for screw

- Index

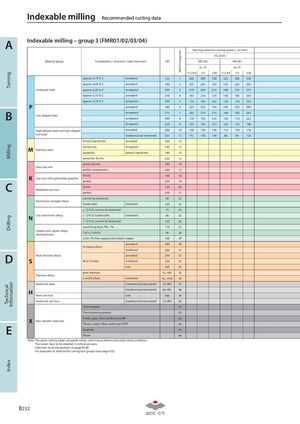

TurningMillingDrillingTechnicalInformationIndex Machining group Indexable milling Recommended cutting data A Indexable milling – group 3 (FMR01/02/03/04) Starting values for cutting speed vc [m/min] HC (CVD) Material group Composition / structure / heat treatment HB YBC302 YBC401 ae / D ae / D 1/1 | 3/4 1/5 1/20 1/1 | 3/4 1/5 1/20 approx. 0,15 % C annealed 125 1 260 300 390 225 260 340 approx. 0,45 % C annealed 190 2 225 255 335 195 225 295 Unalloyed steel approx. 0,45 % C tempered 250 3 210 240 315 180 210 275 approx. 0,75 % C annealed 270 4 185 210 275 160 185 245 approx. 0,75 % C tempered 300 5 170 195 255 150 170 225 P annealed 180 6 225 255 335 195 225 295 B Low-alloyed steel tempered 275 7 185 210 275 160 185 245tempered3008170195255150170225 tempered 350 9 145 165 215 125 145 190 High-alloyed steel and high-alloyed annealed 200 10 130 150 195 115 130 170 tool steel hardened and tempered 325 11 95 105 140 80 95 125 ferritic/martensitic annealed 200 12 M Stainless steel martensitic tempered 240 13 austenitic quench hardened 180 14 austenitic-ferritic 230 15 perlitic/ferritic 180 16 Grey cast iron perlitic (martensitic) 260 17 K Cast iron with spheroidal graphite ferritic 160 18 perlitic 250 19 C Malleable cast iron ferritic 130 20 perlitic 230 21 cannot be hardened 60 22 Aluminium wrought alloys hardenable hardened 100 23 ≤ 12 % Si, cannot be hardened 75 24 N Cast aluminium alloys ≤ 12 % Si, hardenable hardened 90 25 > 12 % Si, cannot be hardened 130 26 machining steel, PB> 1% 110 27 Copper and copper alloys(bronze/brass)CuZn, CuSnZn 90 28 CuSn, Pb-free copper, electrolytic copper 100 29 annealed 200 30 Fe-based alloys hardened 280 31 D Heat-resistant alloysS Ni or Co bass annealedhardened 250 3235033 cast 320 34 pure titanium Rm 400 35 Titanium alloys α and β alloys hardened Rm 1050 36 Hardened steel hardened and tempered 55 HRC 37 H hardened and tempered 60 HRC 38 Hard cast iron cast 400 39 Hardened cast iron hardened and tempered 55 HRC 40 Thermoplasts 41 Thermosetting plastics 42 X Non-metallic materials Plastic, glass-fibre reinforced GFRP 43 Plastic, carbon fibre reinforced CFRP 44 E Graphite 45 Wood 46 Note: The given cutting values are guide values, which were determined under ideal conditions. The values have to be adapted in individual cases. Feed rate recommendations on page B248. For examples of material for cutting tool groups view page D22. B 232

Каталог ZCC-CT сверла со сменными пластинами

Каталог ZCC-CT сверла со сменными пластинами Каталог ZCC-CT сверла монолитные

Каталог ZCC-CT сверла монолитные Каталог ZCC-CT оснастка

Каталог ZCC-CT оснастка Каталог ZCC-CT расточные системы

Каталог ZCC-CT расточные системы Каталог ZCC-CT фрезы со сменными пластинами

Каталог ZCC-CT фрезы со сменными пластинами Каталог ZCC-CT фрезы монолитные

Каталог ZCC-CT фрезы монолитные