Обший каталог Yamawa 2016 - 2017 - страница 684

Навигация

- CONTENTS

- Basic concept of new product system for various steels

- System chart of taps for blind holes on ISO P - steel ~ 45HRC

- System chart of taps for through holes on ISO P - steel ~ 45HRC

- System chart of taps for blind holes on ISO M - stainless steel

- System chart of taps for through holes on ISO M - stainless steel

- System chart of taps for blind holes on ISO K - cast iron

- System chart of taps for through holes on ISO K - cast iron

- System chart of taps for blind holes on ISO N - non ferrous materials

- System chart of taps for through holes on ISO N - non ferrous materials

- System chart of forming taps for ISO P steel and ISO M stainless steel

- System chart of forming taps for ISO N non ferrous materials

- System chart of taps for blind holes on ISO S-heat resistant alloys

- System chart of taps for through holes on ISO S-heat resistant alloys

- System chart of taps for blind and through holes on ISO H - hardened steel 45 ~ 63HRC

- ISO Code

- List of work materials

- Selection chart of taps

- YAMAWA PRODUCT LINE-UPS

- Spiral Fluted Tap Series for blind hole

- Spiral Fluted Tap Series for through hole

- Spiral Pointed Tap Series

- Straight Fluted Tap Series

- Cemented Carbide Tap Series

- Roll Tap Series

- Dies

- Center Drills

- Spiral Fluted Tap Series for blind hole

- Spiral Fluted Tap Series for through hole

- Spiral Pointed Tap Series

- Hand Tap Series

- Cemented Carbide Tap Series

- Roll Tap Series

- Check Pin Series

- Pipe Tap Series

- Dies

- Spiral Fluted Tap Series for blind hole

- Spiral Fluted Tap Series for through hole

- Spiral Pointed Tap Series

- Hand Tap Series

- Cemented Carbide Tap Series

- Roll Tap Series

- Special Thread Taps / Simple Inspection Tools

- Pipe Tap Series

- Thread Mills

- Dies

- Center Drills/Centering Tools

- Explanation of icons

- DIN LINE UP

- SPIRAL FLUTED TAP SERIES FOR BLIND HOLE

- SP Spiral Fluted Taps

- SP(Coating) Spiral Fluted Taps, Coated

- SP OX Spiral Fluted Taps, Oxided

- SP(LH) Spiral Fluted Taps for Left Hand Threads

- AU+SP Plus Series Spiral Fluted Taps, Coated

- AUXSP X Series Spiral Fluted Taps, Coated

- AL+SP/AL-SP Spiral Fluted Taps for Aluminum

- LO-SP Low Spiral Fluted Taps

- LO-SP OX Low Spiral Fluted Taps, Oxided

- PH-SP Spiral Fluted Taps for Hard-to-Machine Materials

- E-SP Spiral Fluted Taps for Soft Structural Steels

- SP+VA Spiral Fluted Taps for Stainless Steels

- SP-VA Spiral Fluted Taps for Stainless Steels

- SP-VA(Coating) Spiral Fluted Taps for Stainless Steels, Coated

- SP-BLF Spiral Fluted Taps, Deep Hole Use

- SP-BLF(Coating) Spiral Fluted Taps, Deep Hole Use, Coated

- SP-BLF OX Spiral Fluted Taps, Deep Hole Use, Oxided

- SU2-SP Spiral Fluted Taps for Tough Stainless Steels

- ZEN-B Spiral Fluted Taps for Nickel Base Alloys

- ZET-B Spiral Fluted Taps for Titanium Alloys

- F-SP Spiral Fluted Taps for High Speed Tapping

- HFIHS For Ultra Fast Tapping, Vertical Use. Spiral Fluted Taps for Carbon Steels

- HFISP For Ultra Fast Tapping, Horizontal Use. Low Spiral Fluted Taps for Carbon Steels

- HFAHS For Ultra Fast Tapping, Vertical Use, Spiral Fluted Taps for Aluminum

- HFASP For Ultra Fast Tapping, Horizontal Use, Low Spiral Fluted Taps for Aluminum

- HDISP For Dry Tapping, Blind Hole Use, Spiral Fluted Taps for Steels

- HDASP For Dry Tapping, Blind Hole Use, Spiral Fluted Taps for Aluminum

- SPIRAL FLUTED TAP SERIES FOR THROUGH HOLE

- SL+VA Spiral Fluted Taps for Stainless Steels, Through Hole Use(with LH spiral flutes)

- MHSL Spiral Fluted Taps for Carbon Steels of middle hardness, Through Hole Use(with LH spiral flutes)

- AU+SL Spiral Fluted Taps, Coated, Through Hole Use(with LH spiral flutes)

- AUXSL X Series Spiral Fluted Taps, Coated, Through Hole Use(with LH spiral flutes)

- ZET-P Spiral Fluted Taps for Titanium Alloys, Through Hole Use(with LH spiral flutes)

- F-SL Spiral Fluted Taps for High Speed Tapping, Through Hole Use(with LH spiral flutes)

- HDISL Spiral Fluted Taps for Steels, for Dry Tapping and for Ultra High Speed Tapping, Through Hole Use(with LH spiral flutes)

- SPIRAL POINTED TAP SERIES

- PO Spiral Pointed Taps

- PO(Coating) Spiral Pointed Taps, Coated

- PO OX Spiral Pointed Taps, Oxided

- EH-PO Spiral Pointed Taps for Hard-to-Machine Materials

- PO-VA Spiral Pointed Taps for Stainless Steels

- PO-VA(Coating) Spiral Pointed Taps for Stainless Steels, Coated

- ZEN-P Spiral Pointed Taps for Nickel Base Alloys

- Straight Fluted Tap Series

- HT Straight Fluted and Hand Tap

- EH-HT Straight Fluted Taps for Hard-to-Machine Materials

- GG-HT Straight Fluted Taps for Cast Irons

- GG-HT(Coating) Straight Fluted Taps for Cast Irons, Coated

- GG-HT-OH Straight Fluted Taps for Cast Irons with Internal Coolant Hole

- GG-HT-OH (Coating) Straight Fluted Taps for Cast Irons with Internal Coolant Hole, Coated

- LA-HT Straight Fluted Taps for Die Cast Materials

- AXE-HT AXE Straight Fluted Taps

- CEMENTED CARBIDE TAP SERIES

- CT-FC Carbide Taps for Cast Irons

- EH-CT Carbide Taps for Hard Materials

- UH-CT Carbide Taps for Ultra Hard Materials

- ROLL TAP SERIES

- R-D Thread Forming Taps for Soft Structural Steel Sheets

- R-D(Coating) Thread Forming Taps for Soft Structural Steel Sheets, Coated

- R-D(Coating) Thread Forming Taps for Soft Structural Steel Sheets, Coated

- N+RS/N-RS Thread Forming Taps for Non-Ferrous Materials

- N+RZ/N-RZ Thread Forming Taps for Steels

- OL+RZ Thread Forming Taps for Dry Tapping, Coated

- HP+RZ/HP-RZ High Performance Thread Forming Taps, Coated

- MHRZ Roll Taps for Carbon Steels of Middle Hardness

- Dies

- DPO HSS Spiral Pointed Dies

- Center Drills

- CD-A Low Helix Center Drills-Type A 60°

- CD-R Low Helix Center Drills-Type R

- ANSI LINE UP

- SPIRAL FLUTED TAP SERIES FOR BLIND HOLE

- ISP Spiral Fluted Taps for General Purpose

- SP Spiral Fluted Taps

- SP OX Spiral Fluted Taps,Oxided

- SP Spiral Fluted Taps for Alloy Steels

- LO-SP Low Spiral Fluted Taps for Alloy Steels

- AU+SP Plus Series Spiral Fluted Taps,Coated

- ZELX SS SP Spiral Fluted Taps for Stainless Steels

- ZELX SS SP 6" Long Shank Spiral Fluted Taps for Stainless Steels

- ZELX AL SP Spiral Fluted Taps for Aluminum

- ZELX ALS SP Spiral Fluted Taps for Aluminum

- SP STI Spiral Fluted Taps for Helical Coil Wire Screw Thread Inserts

- SP OX STI Spiral Fluted Taps for Helical Coil Wire Screw Thread Inserts, Oxided

- ZELX TI SP Spiral Fluted Taps for Titanium Alloys

- ZELX NI SP Spiral Fluted Taps for Nickel Base Alloys

- ZELX NI SP STI Spiral Fluted Taps for Nickel Base Alloys, for Helical Coil Wire Screw Thread Inserts

- ZELX FR Spiral Fluted Taps for High Speed Tapping

- SPIRAL FLUTED TAP SERIES FOR THROUGH HOLE

- ZELX TI LHSP Spiral Fluted Taps for Titanium Alloys, Through Hole Use(with LH spiral flutes)

- ZELX FR LHSP Spiral Fluted Taps for High Speed Tapping, Through Hole Use( with LH spiral flutes)

- MHSL Spiral Fluted Taps for Carbon Steels of middle hardness, Through Hole Use (with LH spiral flutes)

- SPIRAL POINTED TAP SERIES

- IPO Spiral Pointed Taps for General Purpose

- PO Spiral Pointed Taps

- PO OX Spiral Pointed Taps, Oxided

- ZELX SS PO Spiral Pointed Taps for Stainless Steels

- ZELX SS PO 6" Long Shank Spiral Pointed Taps for Stainless Steels

- ZELX AL PO Spiral Pointed Taps for Aluminum

- PO STI Spiral Pointed Taps for Helical Coil Wire Screw Thread Inserts

- PO OX STI Spiral Pointed Taps for Helical Coil Wire Screw Thread Inserts, Oxided

- ZELX NI PO Spiral Pointed Taps for Nickel Base Alloys

- ZELX NI PO STI Spiral Pointed Taps for Nickel Base Alloys for Helical Coil Wire Screw Thread Inserts

- HAND TAP SERIES

- IHT Hand Taps for General Purpose

- HT Hand Taps

- HT OX Hand Taps, Oxided

- HT-CI Hand Taps for Cast Irons

- AXE-HT AXE Hand Taps

- HT STI Hand Taps for Helical Coil Wire Screw Thread Inserts

- HT OX STI Hand Taps for Helical Coil Wire Screw Thread Inserts, Oxided

- ZELX MOLD Hand Taps for Hard-to-Machine Materials

- EH-HT Hand Taps for Hard-to-Machine Materials

- CEMENTED CARBIDE TAP SERIES

- ZELX CARB AL Carbide Taps for Light Alloys

- ZELX CARB CI Carbide Taps for Cast Irons

- ROLL TAP SERIES

- N-RZ Thread Forming Taps for Steels

- N-RS Thread Forming Taps for Non-Ferrous Materials

- OL-RZ Thread Forming Taps for Dry Tapping, Coated

- HP-RZ High Performance Thread Forming Taps, Coated

- MHRZ Roll Taps for Carbon Steels of Middle Hardness

- CHECK PIN

- CPC-S Check Pins for Bored Hole in thread cut tapping (Straight Type)

- CPC-T Check Pins for Bored Holes in thread cut tapping (Taper Type)

- PIPE TAP SERIES

- ZELX SS NPT Taps for American Taper Pipe Threads

- ZELX SS NPTF Taps for American Dryseal Taper Pipe Threads

- ZELX MOLD NPT Hand Taps for Hard-to-Machine Materials For American Taper Pipe Threads

- NPT Hand Taps for American Taper Pipe Threads

- INT-NPT Interrupted Taps for American Taper Pipe Threads

- NPT-CI Hand Taps for American Taper Pipe Threads for Cast Irons

- NPTF Hand Taps for American Dryseal Taper Pipe Threads

- NPTF-CI Hand Taps for American Dryseal Taper Pipe Threads, for Cast Irons

- NPS Hand Taps for American Parallel Pipe Threads

- NPSF Hand Taps for American Dryseal Parallel Pipe Threads

- Dies

- PO-D HSS Spiral Pointed Dies

- RD-DA Die Attachment (for Solid Dies)

- JIS LINE UP

- SPIRAL FLUTED TAP SERIES FOR BLIND HOLE

- ISP Spiral Fluted Taps for General Purpose

- SP Spiral Fluted Taps

- SP 1.5P Spiral Fluted Taps 1.5P

- +SP Plus Series Spiral Fluted Taps

- XSP X Series Spiral Fluted Taps

- SP OX Spiral Fluted Taps, Oxided

- +SP OX Plus Series Spiral Fluted Taps, Oxided

- SP LH Spiral Fluted Taps for Left Hand Threads

- SP V Spiral Fluted Taps, Coated

- AU+SP Plus Series Spiral Fluted Taps, Optimum Coating for the tapping

- AUXSP X Series Spiral Fluted Taps, Coated

- LS-SP Long Shank Spiral Fluted Taps

- LS-SP LH Long Shank Spiral Fluted Taps for Left Hand Threads

- LS-SP V Long Shank Spiral Fluted Taps, Coated

- SU+SP/SU-SP Spiral Fluted Taps for Stainless Steels

- SUXSP X Series Spiral Fluted Taps for Stainless Steels

- SU2-SP Spiral Fluted Taps for Tough Stainless Steels

- SU-S-SP Spiral Fluted Taps for Stainless Steels, Deep Hole Use

- S-SP Short Spiral Fluted Taps, Deep Hole Use

- E-SP Spiral Fluted Taps for Soft Structural Steels

- HC+SP/HC-SP Spiral Fluted Taps for High Carbon Steels

- HC+SP OX / HC-SP OX Spiral Fluted Taps for High Carbon Steels, Oxided

- AL+SP/AL-SP Spiral Fluted Taps for Aluminum

- AL-SP 1.5P Spiral Fluted Taps for Aluminum 1.5P

- LO-SP Low Spiral Fluted Taps

- LS-LO-SP Long Shank Low Spiral Fluted Taps

- MC-SP Spiral Fluted Taps with Internal Coolant Hole

- ZET-B Spiral Fluted Taps for Titanium Alloys

- ZEN-B Spiral Fluted Taps for Nickel Base Alloys

- F-SP Spiral Fluted Taps for High Speed Tapping

- HFIHS For Ultra Fast Tapping, Vertical Use. Spiral Fluted Taps for Carbon Steels

- HFISP For Ultra Fast Tapping, Horizontal Use. Low Spiral Fluted Taps for Carbon Steels

- HFAHS For Ultra Fast Tapping, Vertical Use. Spiral Fluted Taps for Aluminum

- HFASP For Ultra Fast Tapping, Horizontal Use. Low Spiral Fluted Taps for Aluminum

- HDISP For Dry Tapping, Blind Hole Use. Spiral Fluted Taps for Steels

- HDASP For Dry Tapping, Blind Hole Use. Spiral Fluted Taps for Aluminum

- SPIRAL FLUTED TAP SERIES FOR THROUGH HOLE

- XSL X Series Spiral Fluted Taps, Through Hole Use (with LH spiral flutes)

- AU+SL Spiral Fluted Taps, Coated, Through Hole Use(with LH spiral flutes)

- AUXSL X Series Spiral Fluted Taps, Coated, Through Hole Use (with LH spiral flutes)

- SU+SL Spiral Fluted Taps for Stainless Steels, Through Hole Use(with LH spiral flutes)

- SUXSL X Series Spiral Fluted Taps for Stainless Steels, Through Hole Use (with LH spiral flutes)

- ZET-P Spiral Fluted Taps for Titanium Alloys, Through Hole Use (with LH spiral flutes)

- F-SL Spiral Fluted Taps for High Speed Tapping, Through Hole Use (with LH spiral flutes)

- HDISL Spiral Fluted Taps for Steels, for Dry Tapping and for Ultra High Speed Tapping,Through Hole Use (with LH spiral flutes)

- MHSL Spiral Fluted Taps for Carbon Steels of middle hardness, Through Hole Use (with LH spiral flutes)

- SPIRAL POINTED TAP SERIES

- IPO Spiral Pointed Taps for General Purpose

- PO Spiral Pointed Taps

- +PO Plus Series Spiral Pointed Taps

- PO OX Spiral Pointed Taps, Oxided

- +PO OX Plus Series Spiral Pointed Taps, Oxided

- PO LH Spiral Pointed Taps for Left Hand Threads

- PO V Spiral Pointed Taps, Coated

- LS-PO Long Shank Spiral Pointed Taps

- LS-PO V Long Shank Spiral Pointed Taps, Coated

- SU+PO/SU-PO Spiral Pointed Taps for Stainless Steels

- S-PO Short Spiral Pointed Taps for Deep Hole Use

- HC+PO/HC-PO Spiral Pointed Taps for High Carbon Steels

- MC-PO Spiral Pointed Taps with Internal Coolant

- EH-PO Spiral Pointed Taps for Hard-to-Machine Materials

- ZEN-P Spiral Pointed Taps for Nickel Base Alloys

- HAND TAP SERIES

- IHT Hand Taps for General Purpose

- HT Hand Taps

- HT LH Hand Taps for Left Hand Threads

- LS-HT Long Shank Hand Taps

- LS-HT LH Long Shank Hand Taps for Left Hand Threads

- LS-HT V Long Shank Hand Taps, Coated

- SU-HT Hand Taps for Stainless Steels

- FC-HT Hand Taps for Cast Irons

- LA-HT Hand Taps for Die Cast Materials

- AXE-HT AXE Hand Taps

- MG-HT Hand Taps with Short Chamfer for Magnesium Alloy Castings

- AL-HT Hand Taps for Helical Coil Wire Screw Thread Inserts

- PL1 Hand Taps for Plastics

- MC-HT Hand Taps with Internal Coolant Hole

- EH-HT Hand Taps for Hard-to-Machine Materials

- CEMENTED CARBIDE TAP SERIES

- N-CT LA Carbide Taps for Light Alloys

- N-CT FC Carbide Taps for Cast Irons

- N-CT-PO Spiral Pointed Carbide Taps

- MC-AD-CT Carbide Taps with Oil Hole

- EH-CT Carbide Taps for Hard Materials

- UH-CT Carbide Taps for Ultra Hard Materials

- HFACT-P Carbide Taps for Ultra Fast Tappings, Through Hole Use, for Aluminum

- HFACT-B Carbide Taps for Ultra Fast Tappings, Blind Hole Use, for Aluminum

- HFICT-P Carbide Taps for Ultra Fast Tappings, Through Hole Use, for Cast Irons

- HFICT-B Carbide Taps for Ultra Fast Tappings, Blind Hole Use, for Cast Irons

- ROLL TAP SERIES

- N+RZ/N-RZ Thread Forming Taps for Steels

- LS-N-RZ Long Shank Thread Forming Taps for Steels

- N+RS/N-RS Thread Forming Taps for Non-Ferrous Materials

- LS-N-RS Long Shank Thread Forming Taps for Non-Ferrous Materials

- R+V Thread Forming Taps, Coated

- OL+RZ/OL-RZ Thread Forming Taps for Dry Tapping, Coated

- HP+RZ/HP-RZ High Performance Thread Forming Taps, Coated

- SC-TL-RZ Torqueless Thread Forming Taps with short chamfer

- SURZ SU Thread Forming Taps

- MHRZ Roll Taps for Carbon Steels of Middle Hardness

- SPECIAL THREAD TAPS / SIMPLE INSPECTION TOOLS

- MS+RS Roll Taps for Miniature Threads

- HPsRZ High Performance Roll Taps for Miniature Threads

- SIT Simple Thread Inspection Tools

- SITD(Tandem Type) Simple Thread Inspection Tools, Tandem Type

- CHECK PINS

- CPC-S Check Pins for Bored Hole in thread cut tapping (Straight Type)

- CPC-T Check Pins for Bored Holes in thread cut tapping (Taper Type)

- CPR-S Check Pins for Bored Hole in thread form tapping (Straight Type)

- CPR-T Check Pins for Bored Holes in thread form tapping (Taper Type)

- SA Shank Adjusters

- TA Tap Adapter

- PIPE TAP SERIES

- Rc Hand Taps for Taper Pipe Threads

- PT Hand Taps for Taper Pipe Threads, Long (ℓg) Type

- PT LH Hand Taps for Taper Pipe Threads, Long (ℓg) Type, for LH Threads

- PT-X X Series Hand Taps for Taper Pipe Threads, Short (ℓg) Type

- S-PT Hand Taps for Taper Pipe Threads, Short (ℓg) Type

- S-PT LH Hand Taps for Taper Pipe Threads, Short (ℓg) Type, for LH Threads

- LS-PT Long Shank Hand Taps for Taper Pipe Threads, Long (ℓg) Type

- LS-S-PT Long Shank Hand Taps for Taper Pipe Threads, Short (ℓg) Type

- SP-PT Spiral Fluted Taps for Taper Pipe Threads, Long (ℓg) Type

- SP-S-PT Spiral Fluted Taps for Taper Pipe Threads, Short (ℓg) Type

- SP-PT-X X Series Spiral Fluted Taps for Taper Pipe Threads, Short (ℓg) Type

- LS-SP-PT Long Shank Spiral Fluted Taps for Taper Pipe Threads, Long (ℓg) Type

- LS-SP-S-PT Long Shank Spiral Fluted Taps for Taper Pipe Threads, Short (ℓg) Type

- INT-PT Interrupted Taps for Taper Pipe Threads, Long (ℓg) Type

- INT-S-PT Interrupted Taps for Taper Pipe Threads, Short (ℓg) Type

- LS-INT-PT Long Shank Interrupted Taps for Taper Pipe Threads, Long (ℓg) Type

- LS-INT-S-PT Long Shank Interrupted Taps for Taper Pipe Threads, Short (ℓg) Type

- LC-PT Hand Taps for Taper Pipe Threads, Long (ℓg) Type, for Low Carbon Steels

- LC-S-PT Hand Taps for Taper Pipe Threads, Short (ℓg) Type, for Low Carbon Steels

- SU-PT Hand Taps for Taper Pipe Threads, Long (ℓg) Type, for Stainless Steels

- SU-S-PT Hand Taps for Taper Pipe Threads, Short (ℓg) Type, for Stainless Steels

- FC-PT Hand Taps for Taper Pipe Threads, Long (ℓg) Type, for Cast Irons

- FC-S-PT Hand Taps for Taper Pipe Threads, Short (ℓg) Type, for Cast Irons

- CT-PT Carbide Taps for Taper Pipe Threads, Long (ℓg) Type, for Cast Irons

- CT-S-PT Carbide Taps for Taper Pipe Threads, Short (ℓg) Type, for Cast Irons

- Rp Hand Taps for Parallel Pipe Threads

- PS Hand Taps for Parallel Pipe Threads

- PS LH Hand Taps for Parallel Pipe Threads, for LH Threads

- LS-PS Long Shank Hand Taps for Parallel Pipe Threads

- SP-PS Spiral Fluted Taps for Parallel Pipe Threads

- LS-SP-PS Long Shank Spiral Fluted Taps for Parallel Pipe Threads

- CT-PS Carbide Taps for Parallel Pipe Threads

- G Hand Taps for Parallel Pipe Threads

- PF Hand Taps for Parallel Pipe Threads

- PF LH Hand Taps for Parallel Pipe Threads, for LH Threads

- LS-PF Long Shank Hand Taps for Parallel Pipe Threads

- SP-PF Spiral Fluted Taps for Parallel Pipe Threads

- LS-SP-PF Long Shank Spiral Fluted Taps for Parallel Pipe Threads

- SU-PF Hand Taps for Parallel Pipe Threads, for Stainless Steels

- FC-PF Hand Taps for Parallel Pipe Threads, for Cast Irons

- CT-PF Carbide Taps for Parallel Pipe Threads

- NPT Hand Taps for American Taper Pipe Threads

- S-NPT Hand Taps for American Taper Pipe Threads, Short (ℓg) Type

- LS-NPT Long Shank Hand Taps for American Taper Pipe Threads

- SP-NPT Spiral Fluted Taps for American Taper Pipe Threads

- LS-SP-S-NPT Long Shank Spiral Fluted Taps for American Taper Pipe Threads, Short (ℓg) Type

- INT-NPT Interrupted Taps for American Taper Pipe Threads

- INT-S-NPT Interrupted Taps for American Taper Pipe Threads, Short (ℓg) Type

- NPTF Hand Taps for American Dryseal Taper Pipe Threads

- LS-NPTF Long Shank Hand Taps for American Dryseal Taper Pipe Threads

- NPS Hand Taps for American Parallel Pipe Threads

- NPSF Hand Taps for American Dryseal Parallel Pipe Threads

- THREAD MILLS

- MC-CSLC Carbide Thread Mills for Metric Internal Threads

- MC-CSLC Carbide Thread Mills for Taper Pipe Threads

- MC-CSLC Carbide Thread Mills for Parallel Pipe Threads

- MC-HLC Thread Mills for Metric Internal Threads

- MC-HLC Thread Mills for Taper Pipe Threads

- MC-HLC Thread Mills for Parallel Pipe Threads

- Dies

- D Solid Round Dies

- D LH Solid Round Dies for Left Hand Threads

- D PF Solid Round Dies for Parallel Pipe Threads

- D PF LH Solid Round Dies for Parallel Pipe Threads, for Left Hand Threads

- D NPSM Solid Round Dies for American Parallel Pipe Threads

- D PT Solid Round Dies for Taper Pipe Threads

- D PT LH Solid Round Dies for Taper Pipe Threads, for Left Hand Threads

- D NPT Solid Round Dies for American Taper Pipe Threads

- D NPTF Solid Round Dies for American Dryseal Taper Pipe Threads

- MS-RS-D/RS-D Rolling Dies

- N-RSD New Rolling Dies

- RD-DH Die Holders for Solid Dies

- RD-DC Die Collets for Die Holders

- RD-DA Die attachment (Designed Specially for Solid Round Dies)

- Center Drills/Centering Tools

- CESA High Helix Center Drills-JIS Type A 60°

- CE-S High Helix Center Drills-Type A 60°

- CD-S Low Helix Center Drills-Type A 60°

- CD-S LH Low Helix Center Drills-Type A 60°, Left Hand Cut

- CE-S V High Helix Center Drills-Type A 60°, Coated

- C-CD-S Carbide Center Drills-Type A 60°

- CE-SL Long Shank High Helix Center Drills-Type A 60°

- CD-SL Long Shank Low Helix Center Drills-Type A 60°

- CE-SL V Long Shank High Helix Center Drills-Type A 60°, Coated

- CD-SL V Long Shank Low Helix Center Drills-Type A 60°, Coated

- C-CD-SL Long Shank Carbide Center Drills-Type A 60°

- CEQA High Helix Center Drills-JIS Type A 90°

- CE-Q High Helix Center Drills-Type A 90°

- CD-Q Low Helix Center Drills-Type A 90°

- CD-Q LH Low Helix Center Drills - Type A 90°, Left Hand Cut

- CE-Q V High Helix Center Drills-Type A 90°, Coated

- CD-Q V Low Helix Center Drills-Type A 90°, Coated

- C-CD-Q Low Helix Carbide Center Drills-Type A 90°

- CE-QL Long Shank High Helix Center Drills-Type A 90°

- CE-QL V Long Shank High Helix Center Drills-Type A 90°, Coated

- C-CD-QL Long Shank Carbide Center Drills-Type A 90°

- CEIR High Helix Center Drills-JIS Type R

- CD-R Low Helix Center Drills-Type R

- CESB High Helix Center Drills-JIS Type B 60°

- CESC High Helix Center Drills-JIS Type C 60°

- MHCDS Center Drills for Carbon Steels of Middle Hardness for running at High Speed

- JOINT TOOLS

- JO-CES Joint- High Helix Center Drills-Type A 60°

- JO-CES V Joint- High Helix Center Drills-Type A 60°, Coated

- JO-CDS Joint- Low Helix Center Drills-Type A 60°

- JO-CDS V Joint- Low Helix Center Drills-Type A 60°, Coated

- JO-C-CDS Joint- Low Helix Carbide Center Drills-Type A 60°

- JO-PEQ Joint- Point Drills 90°

- JO-PEQ V Joint- Point Drills 90°, Coated

- JO-C-PEQ V Joint- Carbide Point Drills 90°, Coated

- JO-NCSD V Joint- NC Starting Drills for Beveling, Coated

- JO-CSQM Joint- Countersinks 90°, Drilling Machine Use

- JO-HOLDER Holders for Joint Tools, for 150mm and for 200mm

- POINT DRILLS

- PE-Q Point Drills 90°

- PE-Q V Point Drills 90°, Coated

- C-PE-Q V Carbide Point Drills 90°, Coated

- PE-QL V Long Shank Point Drills 90°, Coated

- PE-S Point Drills 60°

- PE-S V Point Drills 60°, Coated

- C-PE-S V Carbide Point Drills 60°,Coated

- PE-SL V Long Shank Point Drills 60°, Coated

- NC-SD V NC Starting Drills for Bevelling (90°), Coated

- NC-SD NC Starting Drills for Center Positioning (125°)

- CS-Q Countersinks 90°, Machining Center Use

- CS-QM Countersinks 90°and 60°, Drilling Machine Use

- CS-G Submarine Gate Cutter, 20°, 30°

- YAMAWA LINE-UPS ARRANGED ON SIZES

- Explanation of catalogue contents

- Flowchart : M2 tapping

- M2 Taps

- M2 Dies

- Flowchart : M3 tapping

- M3 Taps

- M3 Dies

- Flowchart : M4 tapping

- M4 Taps

- M4 Dies

- Flowchart : M5 tapping

- M5 Taps

- M5 Dies

- Flowchart : M6 tapping

- M6 Taps

- M6 Dies

- Flowchart : M8 tapping

- M8 Taps

- M8 Dies

- Flowchart : M10 tapping

- M10 Taps

- M10 Dies

- Flowchart : M12 tapping

- M12 Taps

- M12 Dies

- Explanation of catalogue contents

- M1.4-M7 Taps

- M1-M7 Dies

- M9-M24 Taps

- M9-M24 Dies

- M25-M48 Taps

- M26-M36 Dies

- Taps For Unified threads

- Dies For Unified threads

- Taps For Whitworth threads

- Dies For Pipe threads

- Taps For Pg threads

- Dies For American pipe threads

- PRAD system Solution tool

- Specification of corresponding standard blanks (for European market)

- Specification of corresponding standard blanks (for European market)

- Specification of corresponding standard blanks (for European market)

- Specification of corresponding standard blanks (for European market)

- YAMAWA Standard blank Line UP

- TECHNICAL INFORMATION

- 1.Terminology of Taps

- 2.Flutes

- 3.Edge angle and Cutting allowance of taps

- 4.Recommended Tapping Speeds

- 5.Tapping speed and Revolution

- 6.Tapping Torque

- 7.Metric Thread and Gauge Profile

- 8.Length of engagement

- 9.Classes of Internal Threads and Classes of Cutting Taps

- 10.About UNJ Threads

- 11.Accuracy of external threads and accuracy of Dies

- 12.Guide to Thread Forming Taps (Roll Taps)

- 13.How to set the tap's oversize to meet with the coating margin of internal threads

- 14.Tap, Thread Limits

- 15.Bored hole size before tapping ( for thread cutting )

- 16.Bored hole size before tapping ( for thread forming )

- 17.Bar diameter for external threads ( for cutting type dies )

- 18.Bar diameter of external threads (for thread rolling dies)

- 19.Surface Treatment

- 20.Carbide Taps

- 21.Taps for Pipe Threads

- 22.Features of MC-Helical Thread Mills

- 23.Selecting different tap holder combinations by machine feed system

- 24.The mechanism for a tap to cut oversize on an internal thread

- 25.Trouble Shooting

- 26.Center Drills

- 27.Table of recommend centering condition

- 28.Thread Series

- 29.Basic profile of threads

- 30.Symbols for Standard Threads

- 31.Cross chart of thread cutting tool standard

- 32.Hardness conversion table

- 33.Conversion table from inch to millimeter

- 34.Materials used for Cutting Tools

- Searching table by product name

- Alphabet of product name

- Overseas agency

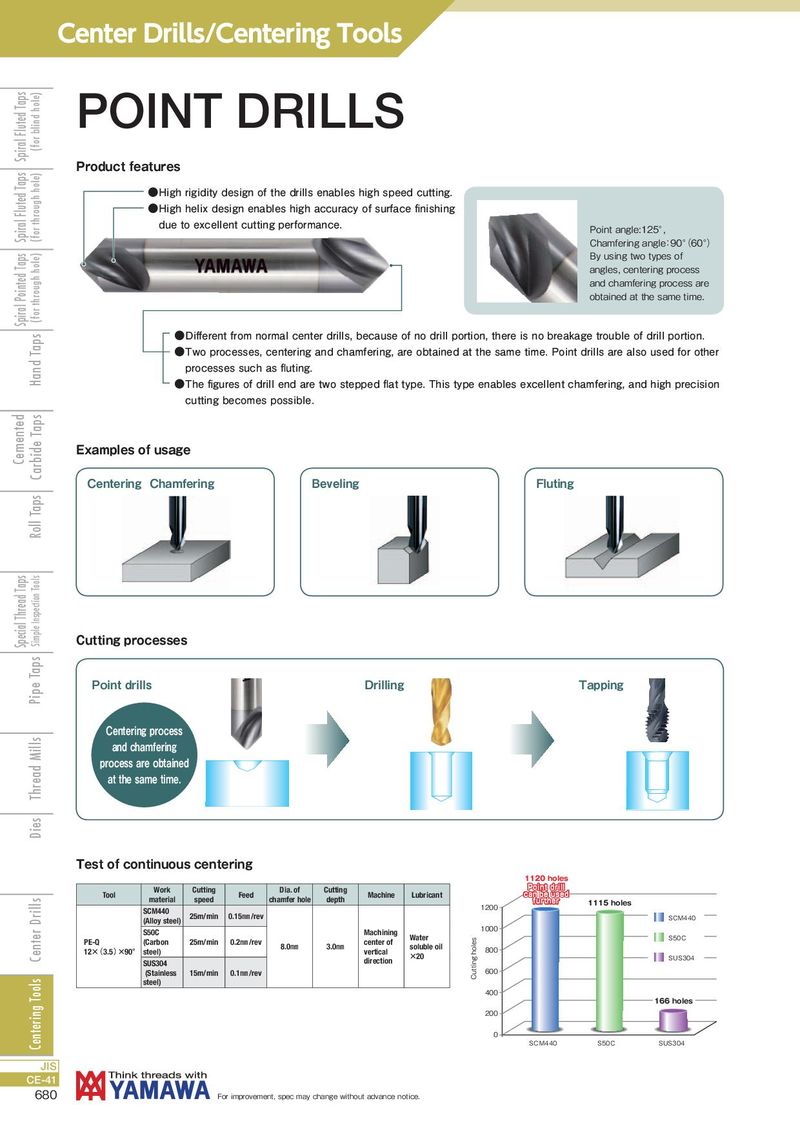

Center Drills/Centering Tools Spiral Fluted Taps (for blind hole) POINT DRILLS Product features Spiral Fluted Taps (for through hole) ●High rigidity design of the drills enables high speed cutting. ●High helix design enables high accuracy of surface finishing due to excellent cutting performance. Point angle:125°, Chamfering angle:90(°60°) Spiral Pointed Taps (for through hole) By using two types of angles, centering process and chamfering process are obtained at the same time. Hand Taps ●Different from normal center drills, because of no drill portion, there is no breakage trouble of drill portion. ●Two processes, centering and chamfering, are obtained at the same time. Point drills are also used for other processes such as fluting. ●The figures of drill end are two stepped flat type. This type enables excellent chamfering, and high precision cutting becomes possible. Cemented Carbide Taps Examples of usage Centering Chamfering Beveling Fluting Roll Taps Special Thread Taps Simple Inspection Tools Cutting processes Pipe Taps Point drills Drilling Tapping Thread Mills Centering process and chamfering process are obtained at the same time. Dies Test of continuous centering 1120 holes oint rill 1120 holes Work Cutting Dia. of Cutting c n e use 1115c oint rill hnfoulertes use Tool material speed Feed chamfer hole depth Machine Lubricant furt er er Drills 1200 1200 1115 holes SCM440 25m/min 0.15㎜ /rev (Alloy steel) 1000 SCM440 1000 SCM440 Center S50C Machining Cutting holes Water S50C PE-Q (Carbon 25m/min 0.2㎜ /rev center of Cutting holes 8.0㎜ 3.0㎜ 80s0oluble oil S50C 12×(3.5)×90° steel) vertical ×20 800 SUS304 direction SUS304 600 SUS304 (Stainless 15m/min 0.1㎜ /rev 600 Tools steel) 400 400 166 holes 166 holes Centering 200 200 0 0 SCM440 S50C SUS304 SCM440 S50C SUS304 JIS CE-41 680 For improvement, spec may change without advance notice.

Каталоги Yamawa твердосплавные метчики для закаленной стали

Каталоги Yamawa твердосплавные метчики для закаленной стали Краткое руководство Yamawa по каталогам

Краткое руководство Yamawa по каталогам Общий каталог Yamawa 2021

Общий каталог Yamawa 2021 Общий каталог Yamawa 2022 - 2023

Общий каталог Yamawa 2022 - 2023