Каталог Sumitomo твердосплавные пластины - страница 62

Навигация

Каталог Sumitomo фрезы со сменными пластинами

Каталог Sumitomo фрезы со сменными пластинами Каталог Sumitomo модульные системы для револьверных головок токарных станков

Каталог Sumitomo модульные системы для револьверных головок токарных станков Каталог Sumitomo токарные резцы (державки) для внутреннего точения

Каталог Sumitomo токарные резцы (державки) для внутреннего точения Каталог Sumitomo сверла и развертки

Каталог Sumitomo сверла и развертки Каталог Sumitomo пластины с алмазными вставками Sumidia

Каталог Sumitomo пластины с алмазными вставками Sumidia Каталог Sumitomo твердосплавные заготовки

Каталог Sumitomo твердосплавные заготовки - B001

- B002

- B003

- B004

- B005

- B006

- B007

- B008

- B009

- B010

- B011

- B012

- B013

- B014

- B015

- B016

- B017

- B018

- B019

- B020

- B021

- B022

- B023

- B024

- B025

- B026

- B027

- B028

- B029

- B030

- B031

- B032

- B033

- B034

- B035

- B036

- B037

- B038

- B039

- B040

- B041

- B042

- B043

- B044

- B045

- B046

- B047

- B048

- B049

- B050

- B051

- B052

- B053

- B054

- B055

- B056

- B057

- B058

- B059

- B060

- B061

- B062

- B063

- B064

- B065

- B066

- B067

- B068

- B069

- B070

- B071

- B072

- B073

- B074

- B075

- B076

- B077

- B078

- B079

- B080

- B081

- B082

- B083

- B084

- B085

- B086

- B087

- B088

- B089

- B090

- B091

- B092

- B093

- B094

- B095

- B096

- B097

- B098

- B099

- B100

- B101

- B102

- B103

- B104

- B105

- B106

- B107

- B108

- B109

- B110

- B111

- B112

- B113

- B114

- B115

- B116

- B117

- B118

- B119

- B120

- B121

- B122

- B123

- B124

- B125

- B126

- B127

- B128

- B129

- B130

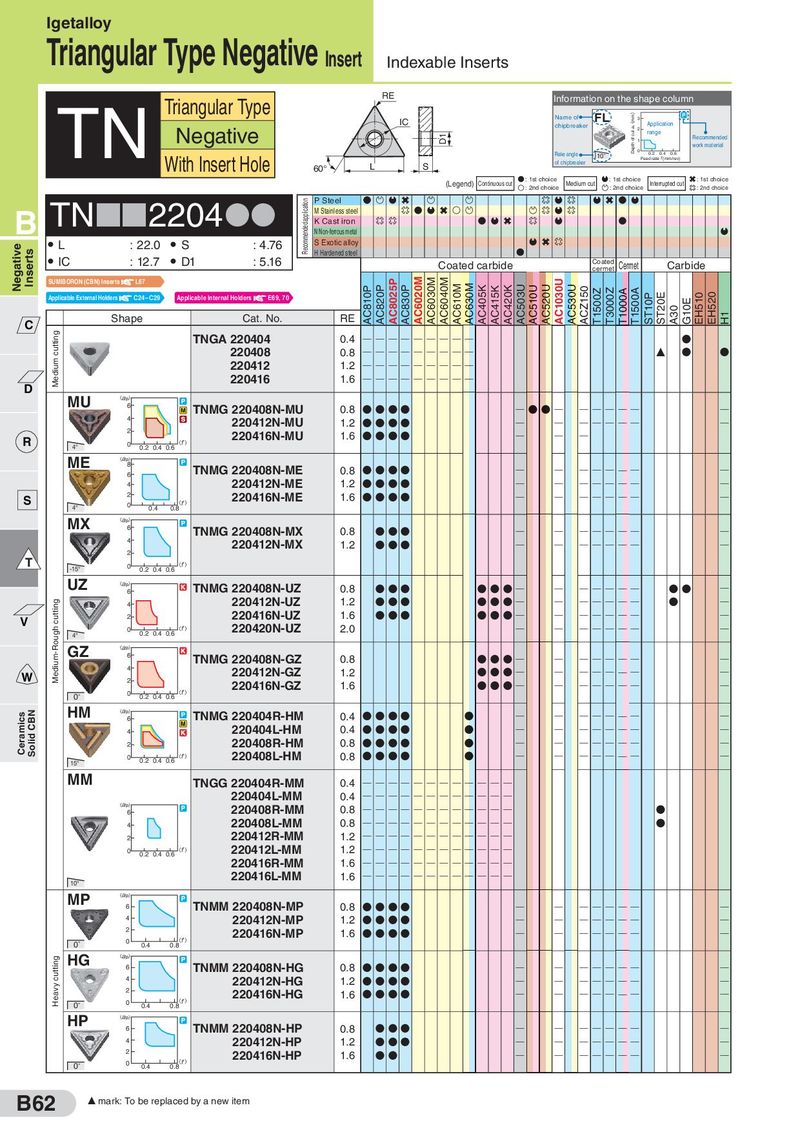

Igetalloy Triangular Type Negative Insert Indexable Inserts Triangular Type RE Information on the shape column TN IC Name of FL ap(mm) 3 Negative chipbreaker Application Depth of cut 2 range D1 1 Recommended work material Rake angle 0 0.2 0.4 0.6 With Insert Hole 10° Feed rate f (mm/rev) 60° L S of chipbreaker (Legend) Continuous cut : 1st choice Medium cut : 1st choice Interrupted cut : 1st choice : 2nd choice : 2nd choice : 2nd choice TN¢¢2204 Recommended application P Steel B M Stainless steel K Cast iron N Non-ferrous metal Negative ● L : 22.0 ● S : 4.76 S Exotic alloy Inserts H Hardened steel ● IC : 12.7 ● D1 : 5.16 Coated carbide Coated Cermet Carbide cermet SUMIBORON (CBN) Inserts L67 AC810P AC820P AC8025P AC830P AC6020M AC6030M AC6040M AC610M AC630M AC405K AC415K AC420K AC503U AC510U AC520U AC1030U AC530U Applicable External Holders C24–C29 Applicable Internal Holders E69, 70 ACZ150 T1500Z T3000Z T1000A T1500A ST10P ST20E G10E EH510 EH520 C Shape Cat. No. RE A30 H1 Medium cutting TNGA 220404 0.4 Q Q Q Q QQ QQQ D 220408 0.8 Q Q Q Q QQ QQQ F D D 220412 1.2 Q Q Q Q QQ QQQ D 220416 1.6 Q Q Q Q QQ QQQ MU ( p) 6 TNMG 220408N-MU 0.8 D D D D Q D D Q Q QQ QQ Q 4 220412N-MU 1.2 D D D D Q Q Q QQ QQ Q 2 220416N-MU 1.6 D D D D Q Q Q R 4° 0 0.2 0.4 0.6 ( ) ME ( p) 8 TNMG 220408N-ME 0.8 D D D D Q Q Q QQ QQ Q 6 4 220412N-ME 1.2 D D D D Q Q Q QQ QQ Q S 2 220416N-ME 1.6 D D D D Q Q Q QQ QQ Q 4° 0 ( ) 0.4 0.8 MX ( p) 6 TNMG 220408N-MX 0.8 D D D Q Q Q QQ QQ Q 4 220412N-MX 1.2 D D D Q Q Q QQ QQ Q 2 T -15° 0 0.2 0.4 0.6 ( ) UZ ( p) TNMG 220408N-UZ 0.8 D D D DDD Q Q Q QQ QQ D D Q 6 Medium-Rough cutting 4 220412N-UZ 1.2 D D D DDD Q Q Q QQ QQ D Q V 2 220416N-UZ 1.6 D D D DDD Q Q Q QQ QQ Q 0 0.2 0.4 0.6 ( ) 220420N-UZ 2.0 Q Q Q QQ QQ Q 4° GZ ( p) 6 TNMG 220408N-GZ 0.8 DDD Q Q Q QQ QQ Q 4 220412N-GZ 1.2 DDD Q Q Q QQ QQ Q W 2 220416N-GZ 1.6 DDD Q Q Q QQ QQ Q 0° 0 0.2 0.4 0.6 ( ) Ceramics Solid CBN HM ( p) TNMG 220404R-HM 0.4 D D D D D Q Q Q QQ QQ Q 6 4 220404L-HM 0.4 D D D D D Q Q Q QQ QQ Q 2 220408R-HM 0.8 D D D D D Q Q Q QQ QQ Q 0 0.2 0.4 0.6 ( ) 220408L-HM 0.8 D D D D D Q Q Q QQ QQ Q 15° MM TNGG 220404R-MM 0.4 Q Q Q Q QQ QQQ QQQ 220404L-MM 0.4 Q Q Q Q QQ QQQ QQQ ( p) 220408R-MM 0.8 Q Q Q Q QQ QQQ QQQ D 6 4 220408L-MM 0.8 Q Q Q Q QQ QQQ QQQ D 2 220412R-MM 1.2 Q Q Q Q QQ QQQ QQQ 0 0.2 0.4 0.6 ( ) 220412L-MM 1.2 Q Q Q Q QQ QQQ QQQ 220416R-MM 1.6 Q Q Q Q QQ QQQ QQQ 10° 220416L-MM 1.6 Q Q Q Q QQ QQQ QQQ MP ( p) 6 TNMM 220408N-MP 0.8 DDDD Q Q Q QQ QQ Q 4 220412N-MP 1.2 DDDD Q Q Q QQ QQ Q 2 220416N-MP 1.6 DDDD Q Q Q QQ QQ Q 0° 0 0.4 ( ) 0.8 Heavy cutting HG ( p) 6 TNMM 220408N-HG 0.8 DDDD Q Q Q QQ QQ Q 4 220412N-HG 1.2 DDDD Q Q Q QQ QQ Q 2 220416N-HG 1.6 DDDD Q Q Q QQ QQ Q 0° 0 0.4 ( ) 0.8 HP ( p) 6 TNMM 220408N-HP 0.8 D D D Q Q Q QQ QQ Q 4 220412N-HP 1.2 D D D Q Q Q QQ QQ Q 2 220416N-HP 1.6 D D Q Q Q QQ QQ Q 0° 0 0.4 ( ) 0.8 B62 F mark: To be replaced by a new item