Каталог Sumitomo твердосплавные пластины - страница 11

Навигация

Каталог Sumitomo фрезы со сменными пластинами

Каталог Sumitomo фрезы со сменными пластинами Каталог Sumitomo модульные системы для револьверных головок токарных станков

Каталог Sumitomo модульные системы для револьверных головок токарных станков Каталог Sumitomo токарные резцы (державки) для внутреннего точения

Каталог Sumitomo токарные резцы (державки) для внутреннего точения Каталог Sumitomo сверла и развертки

Каталог Sumitomo сверла и развертки Каталог Sumitomo пластины с алмазными вставками Sumidia

Каталог Sumitomo пластины с алмазными вставками Sumidia Каталог Sumitomo твердосплавные заготовки

Каталог Sumitomo твердосплавные заготовки - B001

- B002

- B003

- B004

- B005

- B006

- B007

- B008

- B009

- B010

- B011

- B012

- B013

- B014

- B015

- B016

- B017

- B018

- B019

- B020

- B021

- B022

- B023

- B024

- B025

- B026

- B027

- B028

- B029

- B030

- B031

- B032

- B033

- B034

- B035

- B036

- B037

- B038

- B039

- B040

- B041

- B042

- B043

- B044

- B045

- B046

- B047

- B048

- B049

- B050

- B051

- B052

- B053

- B054

- B055

- B056

- B057

- B058

- B059

- B060

- B061

- B062

- B063

- B064

- B065

- B066

- B067

- B068

- B069

- B070

- B071

- B072

- B073

- B074

- B075

- B076

- B077

- B078

- B079

- B080

- B081

- B082

- B083

- B084

- B085

- B086

- B087

- B088

- B089

- B090

- B091

- B092

- B093

- B094

- B095

- B096

- B097

- B098

- B099

- B100

- B101

- B102

- B103

- B104

- B105

- B106

- B107

- B108

- B109

- B110

- B111

- B112

- B113

- B114

- B115

- B116

- B117

- B118

- B119

- B120

- B121

- B122

- B123

- B124

- B125

- B126

- B127

- B128

- B129

- B130

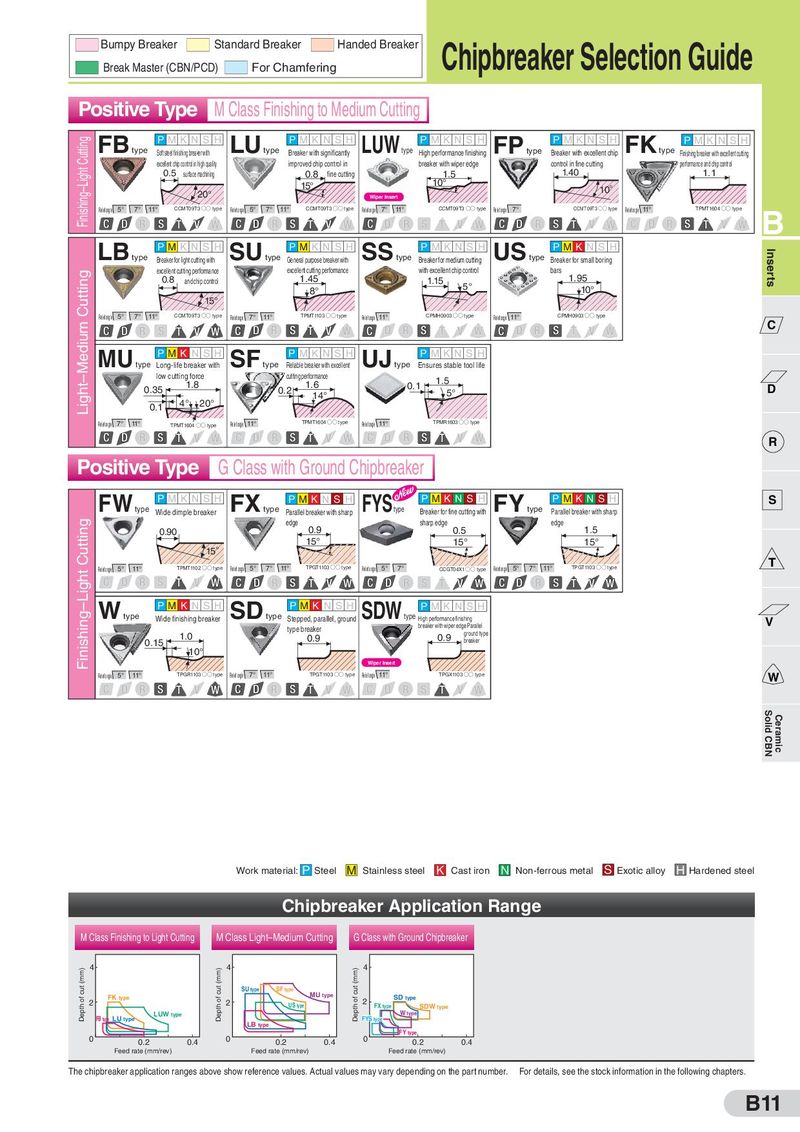

Bumpy Breaker Standard Breaker Handed Breaker Chipbreaker Selection Guide Break Master (CBN/PCD) For Chamfering Positive Type M Class Finishing to Medium Cutting Finishing–Light Cutting FB type PMKNSH LU type PMKNSH LUW type PMKNSH FP type PMKNSH FK type PMKNSH Soft steel finishing breaker with Breaker with significantly High performance finishing Breaker with excellent chip Finishing breaker with excellent cutting excellent chip control in high quality improved chip control in breaker with wiper edge control in fine cutting performance and chip control 0.5 surface machining 0.8 fine cutting 1.5 1.40 1.1 15° 10° 10° 20° Wiper Insert Relief angle 5° 7° 11° CCMT09T3 ○○ type Relief angle 5° 7° 11° CCMT09T3 ○○ type Relief angle 7° 11° CCMT09T3 ○○ type Relief angle 7° CCMT09T3 ○○ type Relief angle 11° TPMT1604 ○○ type B C D R S T V W C D R S T V W C D R S T V W C D R S T V W C D R S T V W LB type PMKNSH SU type PMKNSH SS type PMKNSH US type PMKNSH Inserts Breaker for light cutting with General purpose breaker with Breaker for medium cutting Breaker for small boring Light–Medium Cutting excellent cutting performance excellent cutting performance with excellent chip control bars 1.95 0.8 and chip control 1.45 1.15 5° 8° 10° 15° Relief angle 5° 7° 11° CCMT09T3 ○○ type Relief angle 7° 11° TPMT1103 ○○ type Relief angle 11° CPMH0903 ○○ type Relief angle 11° CPMH0903 ○○ type C D R S T V W C D R S T V W C D R S T V W C D R S T V W C MU type PMKNSH SF type PMKNSH UJ type PMKNSH Long-life breaker with Reliable breaker with excellent Ensures stable tool life low cutting force cutting performance 1.5 0.35 1.8 0.2 1.6 0.1 5° D 4° 20° 14° 0.1 Relief angle 7° 11° TPMT1604 ○○ type Relief angle 11° TPMT1604 ○○ type Relief angle 11° TPMR1603 ○○ type C D R S T V W C D R S T V W C D R S T V W R Positive Type G Class with Ground Chipbreaker FW type PMKNSH FX type PMKNSH FYS type PMKNSH FY type PMKNSH S Wide dimple breaker Parallel breaker with sharp Breaker for fine cutting with Parallel breaker with sharp Finishing–Light Cutting edge 0.9 sharp edge 0.5 edge 1.5 0.90 15° 15° 15° 15° Relief angle 5° 11° TPMT1102 ○○ type Relief angle 5° 7° 11° TPGT1103 ○○ type Relief angle 5° 7° CCGT04X1 ○○ type Relief angle 5° 7° 11° TPGT1103 ○○ type T C D R S T V W C D R S T V W C D R S T V W C D R S T V W W type PMKNSH SD type PMKNSH SDW type PMKNSH Wide finishing breaker Stepped, parallel, ground High performance finishing V type breaker breaker with wiper edge Parallel 1.0 0.9 0.9 ground type 0.15 breaker 10° Wiper Insert Relief angle 5° 11° TPGR1103 ○○ type Relief angle 7° 11° TPGT1103 ○○ type Relief angle 11° TPGX1103 ○○ type W C D R S T V W C D R S T V W C D R S T V W Solid CBN Ceramic Work material: P Steel M Stainless steel K Cast iron N Non-ferrous metal S Exotic alloy H Hardened steel Chipbreaker Application Range M Class Finishing to Light Cutting M Class Light–Medium Cutting G Class with Ground Chipbreaker (mm) 4 (mm) 4 (mm) 4 cut cut SU type SF type MU type cut of 2 FK type of 2 of 2 SD type Depth Depth US type Depth FX type SDW type LU type LUW type FYS W type FB type type LB type 0 0 0 FY type 0.2 0.4 0.2 0.4 0.2 0.4 Feed rate (mm/rev) Feed rate (mm/rev) Feed rate (mm/rev) The chipbreaker application ranges above show reference values. Actual values may vary depending on the part number. For details, see the stock information in the following chapters. B11