Каталог Sumitomo твердосплавные пластины - страница 16

Навигация

Каталог Sumitomo фрезы со сменными пластинами

Каталог Sumitomo фрезы со сменными пластинами Каталог Sumitomo модульные системы для револьверных головок токарных станков

Каталог Sumitomo модульные системы для револьверных головок токарных станков Каталог Sumitomo токарные резцы (державки) для внутреннего точения

Каталог Sumitomo токарные резцы (державки) для внутреннего точения Каталог Sumitomo сверла и развертки

Каталог Sumitomo сверла и развертки Каталог Sumitomo пластины с алмазными вставками Sumidia

Каталог Sumitomo пластины с алмазными вставками Sumidia Каталог Sumitomo твердосплавные заготовки

Каталог Sumitomo твердосплавные заготовки - B001

- B002

- B003

- B004

- B005

- B006

- B007

- B008

- B009

- B010

- B011

- B012

- B013

- B014

- B015

- B016

- B017

- B018

- B019

- B020

- B021

- B022

- B023

- B024

- B025

- B026

- B027

- B028

- B029

- B030

- B031

- B032

- B033

- B034

- B035

- B036

- B037

- B038

- B039

- B040

- B041

- B042

- B043

- B044

- B045

- B046

- B047

- B048

- B049

- B050

- B051

- B052

- B053

- B054

- B055

- B056

- B057

- B058

- B059

- B060

- B061

- B062

- B063

- B064

- B065

- B066

- B067

- B068

- B069

- B070

- B071

- B072

- B073

- B074

- B075

- B076

- B077

- B078

- B079

- B080

- B081

- B082

- B083

- B084

- B085

- B086

- B087

- B088

- B089

- B090

- B091

- B092

- B093

- B094

- B095

- B096

- B097

- B098

- B099

- B100

- B101

- B102

- B103

- B104

- B105

- B106

- B107

- B108

- B109

- B110

- B111

- B112

- B113

- B114

- B115

- B116

- B117

- B118

- B119

- B120

- B121

- B122

- B123

- B124

- B125

- B126

- B127

- B128

- B129

- B130

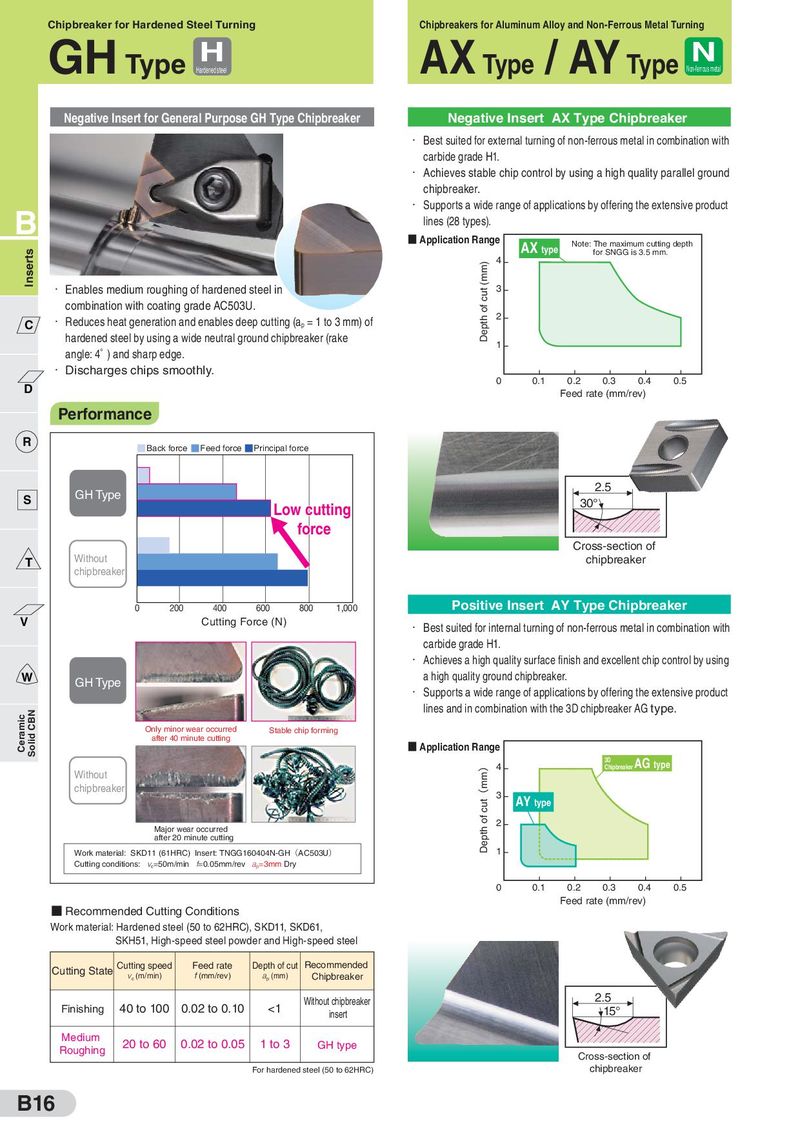

Chipbreaker for Hardened Steel Turning Chipbreakers for Aluminum Alloy and Non-Ferrous Metal Turning GH Type H AX Type / AY Type N Non-ferrous metal Hardened steel Negative Insert for General Purpose GH Type Chipbreaker Negative Insert AX Type Chipbreaker ・ Best suited for external turning of non-ferrous metal in combination with carbide grade H1. ・ Achieves stable chip control by using a high quality parallel ground chipbreaker. B ・ Supports a wide range of applications by offering the extensive product lines (28 types). ■ Application Range AX type Note: The maximum cutting depth Inserts for SNGG is 3.5 mm. (mm) 4 ・ Enables medium roughing of hardened steel in cut 3 combination with coating grade AC503U. of C ・ Reduces heat generation and enables deep cutting (ap = 1 to 3 mm) of Depth 2 hardened steel by using a wide neutral ground chipbreaker (rake 1 angle: 4°) and sharp edge. ・ Discharges chips smoothly. D 0 0.1 0.2 0.3 0.4 0.5 Feed rate (mm/rev) Performance R Back force Feed force Principal force GH Type 2.5 S Low cutting 30° force Cross-section of T Without chipbreaker chipbreaker 0 200 400 600 800 1,000 Positive Insert AY Type Chipbreaker V Cutting Force (N) ・ Best suited for internal turning of non-ferrous metal in combination with carbide grade H1. ・ Achieves a high quality surface finish and excellent chip control by using W GH Type a high quality ground chipbreaker. ・ Supports a wide range of applications by offering the extensive product Ceramic Solid CBN lines and in combination with the 3D chipbreaker AG type. Only minor wear occurred Stable chip forming after 40 minute cutting ■ Application Range ︶ 4 AG 3D type Chipbreaker Without mm chipbreaker ︵ 3 Depth of cut AY type Major wear occurred 2 after 20 minute cutting Work material: SKD11 (61HRC) Insert: TNGG160404N-GH(AC503U) 1 Cutting conditions: vc=50m/min f=0.05mm/rev ap=3mm Dry 0 0.1 0.2 0.3 0.4 0.5 Feed rate (mm/rev) ■ Recommended Cutting Conditions Work material: Hardened steel (50 to 62HRC), SKD11, SKD61, SKH51, High-speed steel powder and High-speed steel Cutting State Cutting speed Feed rate Depth of cut Recommended vc (m/min) f (mm/rev) ap (mm) Chipbreaker 40 to 100 0.02 to 0.10 Without chipbreaker 2.5 Finishing <1 insert 15° Medium 20 to 60 0.02 to 0.05 1 to 3 GH type Roughing Cross-section of For hardened steel (50 to 62HRC) chipbreaker B16