Каталог Sumitomo твердосплавные пластины - страница 13

Навигация

Каталог Sumitomo фрезы со сменными пластинами

Каталог Sumitomo фрезы со сменными пластинами Каталог Sumitomo модульные системы для револьверных головок токарных станков

Каталог Sumitomo модульные системы для револьверных головок токарных станков Каталог Sumitomo токарные резцы (державки) для внутреннего точения

Каталог Sumitomo токарные резцы (державки) для внутреннего точения Каталог Sumitomo сверла и развертки

Каталог Sumitomo сверла и развертки Каталог Sumitomo пластины с алмазными вставками Sumidia

Каталог Sumitomo пластины с алмазными вставками Sumidia Каталог Sumitomo твердосплавные заготовки

Каталог Sumitomo твердосплавные заготовки - B001

- B002

- B003

- B004

- B005

- B006

- B007

- B008

- B009

- B010

- B011

- B012

- B013

- B014

- B015

- B016

- B017

- B018

- B019

- B020

- B021

- B022

- B023

- B024

- B025

- B026

- B027

- B028

- B029

- B030

- B031

- B032

- B033

- B034

- B035

- B036

- B037

- B038

- B039

- B040

- B041

- B042

- B043

- B044

- B045

- B046

- B047

- B048

- B049

- B050

- B051

- B052

- B053

- B054

- B055

- B056

- B057

- B058

- B059

- B060

- B061

- B062

- B063

- B064

- B065

- B066

- B067

- B068

- B069

- B070

- B071

- B072

- B073

- B074

- B075

- B076

- B077

- B078

- B079

- B080

- B081

- B082

- B083

- B084

- B085

- B086

- B087

- B088

- B089

- B090

- B091

- B092

- B093

- B094

- B095

- B096

- B097

- B098

- B099

- B100

- B101

- B102

- B103

- B104

- B105

- B106

- B107

- B108

- B109

- B110

- B111

- B112

- B113

- B114

- B115

- B116

- B117

- B118

- B119

- B120

- B121

- B122

- B123

- B124

- B125

- B126

- B127

- B128

- B129

- B130

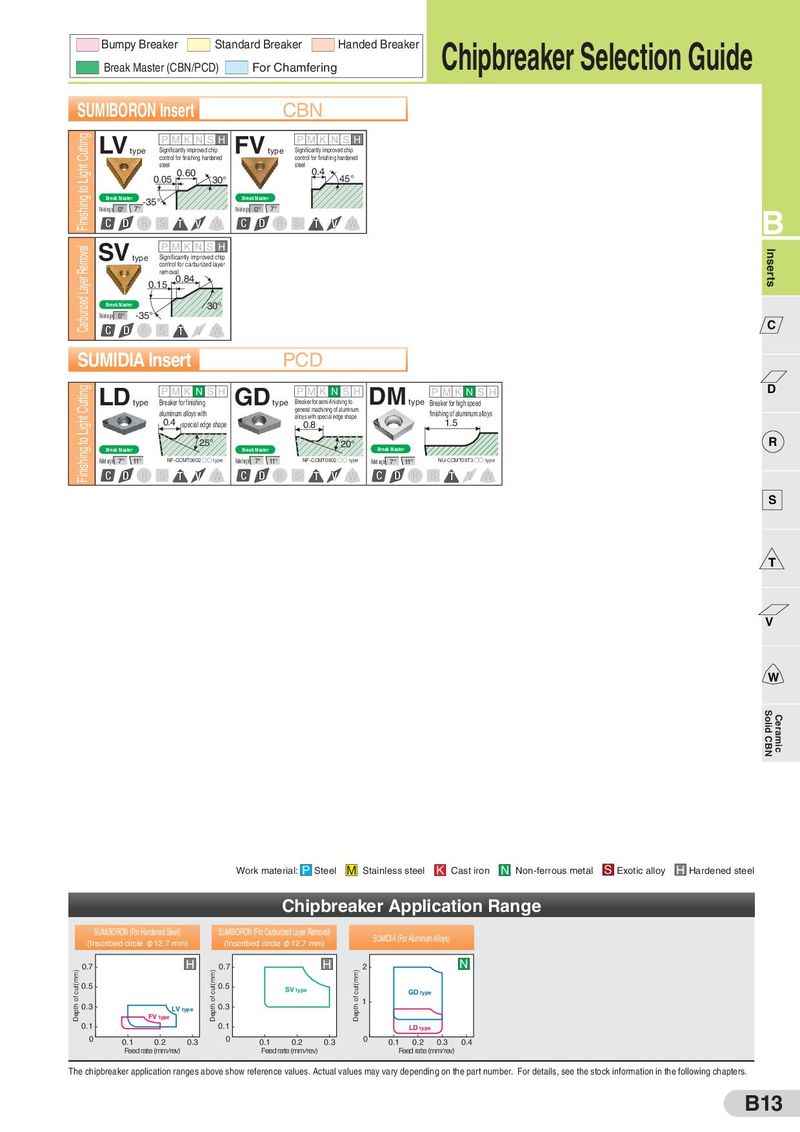

Bumpy Breaker Standard Breaker Handed Breaker Chipbreaker Selection Guide Break Master (CBN/PCD) For Chamfering SUMIBORON Insert CBN Finishing to Light Cutting LV type PMKNSH FV type PMKNSH Significantly improved chip Significantly improved chip control for finishing hardened control for finishing hardened steel steel 0.4 0.05 0.60 45° 30° Break Master -35° Break Master Relief angle 0° 7° Relief angle 0° 7° B C D R S T V W C D R S T V W Carburized Layer Removal SV type PMKNSH Inserts Significantly improved chip control for carburized layer removal 0.84 0.15 Break Master 30° Relief angle 0° -35° C D R S T V W C SUMIDIA Insert PCD Finishing to Light Cutting LD type PMKNSH GD type PMKNSH DM type PMKNSH D Breaker for finishing Breaker for semi-finishing to Breaker for high speed aluminum alloys with general machining of aluminum finishing of aluminum alloys 0.4 alloys with special edge shape 1.5 special edge shape 0.8 25° 20° Break Master R Break Master Break Master Relief angle 7° 11° NF-CCMT0602 ○○ type Relief angle 7° 11° NF-CCMT0602 ○○ type Relief angle 7° 11° NU-CCMT09T3 ○○ type C D R S T V W C D R S T V W C D R S T V W S T V W Solid CBN Ceramic Work material: P Steel M Stainless steel K Cast iron N Non-ferrous metal S Exotic alloy H Hardened steel Chipbreaker Application Range SUMIBORON (For Hardened Steel) SUMIBORON (For Carburized Layer Removal) SUMIDIA (For Aluminum Alloys) (Inscribed circle φ12.7 mm) (Inscribed circle φ12.7 mm) cut(mm) 0.7 H cut(mm) 0.7 H cut(mm) 2 N 0.5 0.5 SV type GD type of of of 1 Depth 0.3 LV type Depth 0.3 Depth FV type 0.1 0.1 LD type 0 0.1 0.2 0.3 0 0.1 0.2 0.3 0 0.1 0.2 0.3 0.4 Feed rate (mm/rev) Feed rate (mm/rev) Feed rate (mm/rev) The chipbreaker application ranges above show reference values. Actual values may vary depending on the part number. For details, see the stock information in the following chapters. B13