Каталог Sumitomo твердосплавные пластины - страница 3

Навигация

Каталог Sumitomo фрезы со сменными пластинами

Каталог Sumitomo фрезы со сменными пластинами Каталог Sumitomo модульные системы для револьверных головок токарных станков

Каталог Sumitomo модульные системы для револьверных головок токарных станков Каталог Sumitomo токарные резцы (державки) для внутреннего точения

Каталог Sumitomo токарные резцы (державки) для внутреннего точения Каталог Sumitomo сверла и развертки

Каталог Sumitomo сверла и развертки Каталог Sumitomo пластины с алмазными вставками Sumidia

Каталог Sumitomo пластины с алмазными вставками Sumidia Каталог Sumitomo твердосплавные заготовки

Каталог Sumitomo твердосплавные заготовки - B001

- B002

- B003

- B004

- B005

- B006

- B007

- B008

- B009

- B010

- B011

- B012

- B013

- B014

- B015

- B016

- B017

- B018

- B019

- B020

- B021

- B022

- B023

- B024

- B025

- B026

- B027

- B028

- B029

- B030

- B031

- B032

- B033

- B034

- B035

- B036

- B037

- B038

- B039

- B040

- B041

- B042

- B043

- B044

- B045

- B046

- B047

- B048

- B049

- B050

- B051

- B052

- B053

- B054

- B055

- B056

- B057

- B058

- B059

- B060

- B061

- B062

- B063

- B064

- B065

- B066

- B067

- B068

- B069

- B070

- B071

- B072

- B073

- B074

- B075

- B076

- B077

- B078

- B079

- B080

- B081

- B082

- B083

- B084

- B085

- B086

- B087

- B088

- B089

- B090

- B091

- B092

- B093

- B094

- B095

- B096

- B097

- B098

- B099

- B100

- B101

- B102

- B103

- B104

- B105

- B106

- B107

- B108

- B109

- B110

- B111

- B112

- B113

- B114

- B115

- B116

- B117

- B118

- B119

- B120

- B121

- B122

- B123

- B124

- B125

- B126

- B127

- B128

- B129

- B130

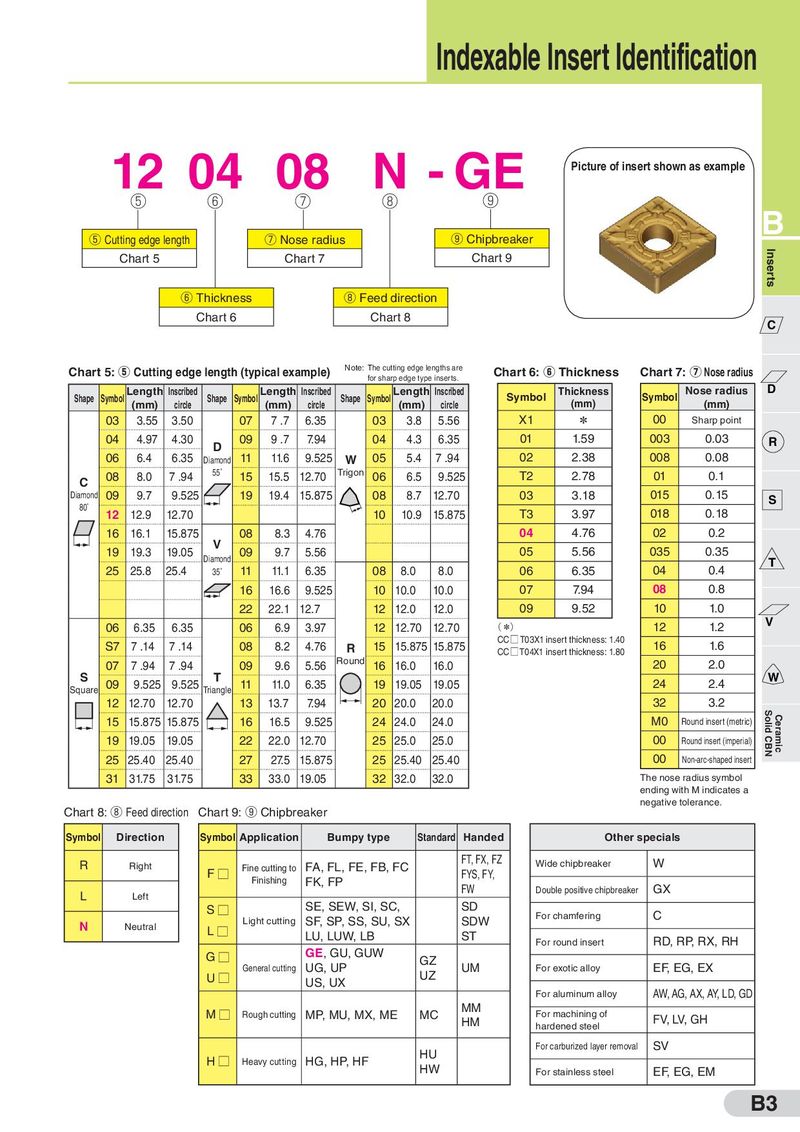

Indexable Insert Identification 12 04 08 N - GE Picture of insert shown as example ⑤ ⑥ ⑦ ⑧ ⑨ ⑤ Cutting edge length ⑦ Nose radius ⑨ Chipbreaker B Chart 5 Chart 7 Chart 9 Inserts ⑥ Thickness ⑧ Feed direction Chart 6 Chart 8 C Chart 5: ⑤ Cutting edge length (typical example) Note: The cutting edge lengths are Chart 6: ⑥ Thickness Chart 7: ⑦ Nose radius for sharp edge type inserts. Shape Symbol Length Inscribed Shape Symbol Length Inscribed Shape Symbol Length Inscribed Symbol Thickness Symbol Nose radius D (mm) circle (mm) circle (mm) circle (mm) (mm) 03 3.55 3.50 07 7 .7 6.35 03 3.8 5.56 X1 * 00 Sharp point 04 4.97 4.30 D 09 9 .7 7.94 04 4.3 6.35 01 1.59 003 0.03 R 06 6.4 6.35 Diamond 11 11.6 9.525 W 05 5.4 7 .94 02 2.38 008 0.08 08 8.0 7 .94 55˚ 15 15.5 12.70 Trigon 06 6.5 9.525 T2 2.78 01 0.1 C Diamond 09 9.7 9.525 19 19.4 15.875 08 8.7 12.70 03 3.18 015 0.15 S 80˚ 12 12.9 12.70 10 10.9 15.875 T3 3.97 018 0.18 16 16.1 15.875 08 8.3 4.76 04 4.76 02 0.2 19 19.3 19.05 V 09 9.7 5.56 05 5.56 035 0.35 Diamond T 25 25.8 25.4 35˚ 11 11.1 6.35 08 8.0 8.0 06 6.35 04 0.4 16 16.6 9.525 10 10.0 10.0 07 7.94 08 0.8 22 22.1 12.7 12 12.0 12.0 09 9.52 10 1.0 06 6.35 6.35 06 6.9 3.97 12 12.70 12.70 (*) 12 1.2 V S7 7 .14 7 .14 08 8.2 4.76 R 15 15.875 15.875 CC □ T03X1 insert thickness: 1.40 16 1.6 CC □ T04X1 insert thickness: 1.80 07 7 .94 7 .94 09 9.6 5.56 Round 16 16.0 16.0 20 2.0 S 09 9.525 9.525 T 11 11.0 6.35 19 19.05 19.05 24 2.4 W Square Triangle 12 12.70 12.70 13 13.7 7.94 20 20.0 20.0 32 3.2 15 15.875 15.875 16 16.5 9.525 24 24.0 24.0 M0 Round insert (metric) Solid CBN Ceramic 19 19.05 19.05 22 22.0 12.70 25 25.0 25.0 00 Round insert (imperial) 25 25.40 25.40 27 27.5 15.875 25 25.40 25.40 00 Non-arc-shaped insert 31 31.75 31.75 33 33.0 19.05 32 32.0 32.0 The nose radius symbol ending with M indicates a negative tolerance. Chart 8: ⑧ Feed direction Chart 9: ⑨ Chipbreaker Symbol Direction Symbol Application Bumpy type Standard Handed Other specials R Right Fine cutting to FA, FL, FE, FB, FC FT, FX, FZ Wide chipbreaker W F□ Finishing FK, FP FYS, FY, L Left FW Double positive chipbreaker GX S□ SE, SEW, SI, SC, SD For chamfering C N Neutral Light cutting SF, SP, SS, SU, SX SDW L□ LU, LUW, LB ST RD, RP, RX, RH For round insert G□ GE, GU, GUW GZ General cutting UG, UP UZ UM For exotic alloy EF, EG, EX U□ US, UX For aluminum alloy AW, AG, AX, AY, LD, GD M□ Rough cutting MP, MU, MX, ME MC MM For machining of HM hardened steel FV, LV, GH HU For carburized layer removal SV H□ Heavy cutting HG, HP, HF HW For stainless steel EF, EG, EM B3