Каталог Sumitomo твердосплавные пластины - страница 19

Навигация

Каталог Sumitomo фрезы со сменными пластинами

Каталог Sumitomo фрезы со сменными пластинами Каталог Sumitomo модульные системы для револьверных головок токарных станков

Каталог Sumitomo модульные системы для револьверных головок токарных станков Каталог Sumitomo токарные резцы (державки) для внутреннего точения

Каталог Sumitomo токарные резцы (державки) для внутреннего точения Каталог Sumitomo сверла и развертки

Каталог Sumitomo сверла и развертки Каталог Sumitomo пластины с алмазными вставками Sumidia

Каталог Sumitomo пластины с алмазными вставками Sumidia Каталог Sumitomo твердосплавные заготовки

Каталог Sumitomo твердосплавные заготовки - B001

- B002

- B003

- B004

- B005

- B006

- B007

- B008

- B009

- B010

- B011

- B012

- B013

- B014

- B015

- B016

- B017

- B018

- B019

- B020

- B021

- B022

- B023

- B024

- B025

- B026

- B027

- B028

- B029

- B030

- B031

- B032

- B033

- B034

- B035

- B036

- B037

- B038

- B039

- B040

- B041

- B042

- B043

- B044

- B045

- B046

- B047

- B048

- B049

- B050

- B051

- B052

- B053

- B054

- B055

- B056

- B057

- B058

- B059

- B060

- B061

- B062

- B063

- B064

- B065

- B066

- B067

- B068

- B069

- B070

- B071

- B072

- B073

- B074

- B075

- B076

- B077

- B078

- B079

- B080

- B081

- B082

- B083

- B084

- B085

- B086

- B087

- B088

- B089

- B090

- B091

- B092

- B093

- B094

- B095

- B096

- B097

- B098

- B099

- B100

- B101

- B102

- B103

- B104

- B105

- B106

- B107

- B108

- B109

- B110

- B111

- B112

- B113

- B114

- B115

- B116

- B117

- B118

- B119

- B120

- B121

- B122

- B123

- B124

- B125

- B126

- B127

- B128

- B129

- B130

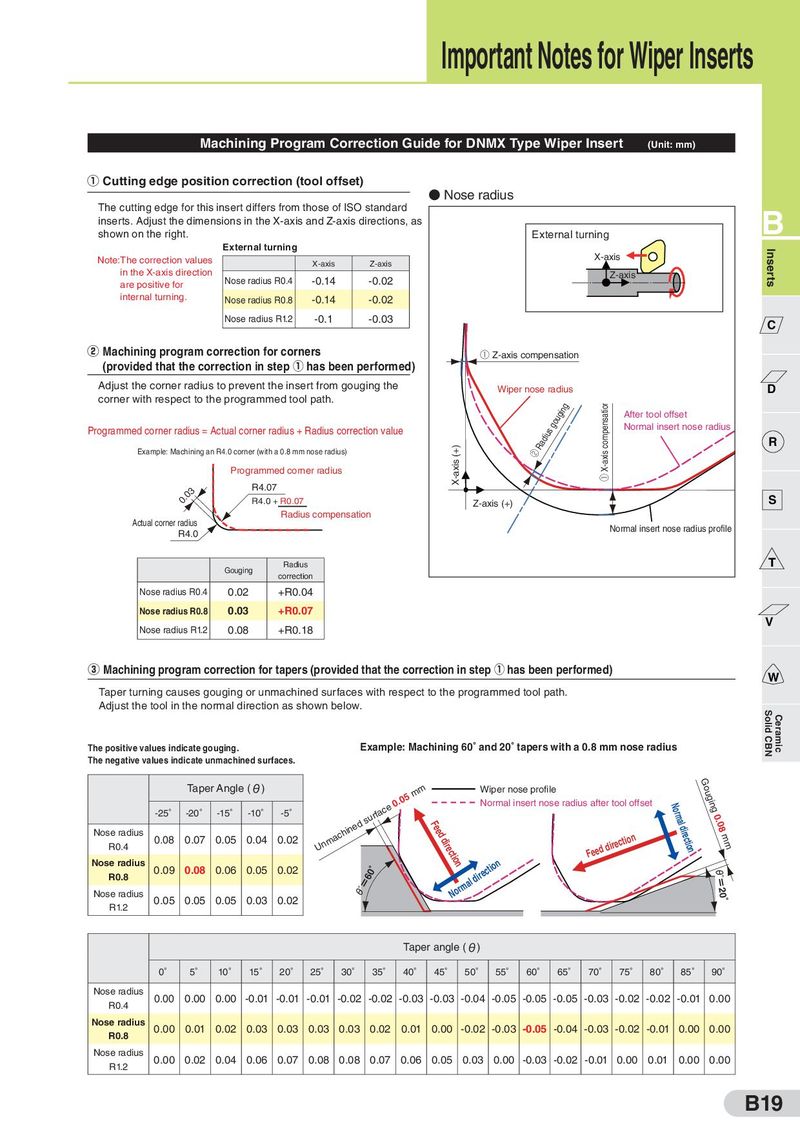

Important Notes for Wiper Inserts Machining Program Correction Guide for DNMX Type Wiper Insert (Unit: mm) ① Cutting edge position correction (tool offset) ● Nose radius The cutting edge for this insert differs from those of ISO standard B inserts. Adjust the dimensions in the X-axis and Z-axis directions, as shown on the right. External turning External turning Inserts Note:The correction values X-axis Z-axis X-axis in the X-axis direction Nose radius R0.4 -0.14 -0.02 Z-axis are positive for internal turning. Nose radius R0.8 -0.14 -0.02 Nose radius R1.2 -0.1 -0.03 C ② Machining program correction for corners X-axis ① Z-axis compensation Z-axis (provided that the correction in step ① has been performed) Adjust the corner radius to prevent the insert from gouging the Wiper nose radius D corner with respect to the programmed tool path. ① X-axis compensation ② Radius gouging After tool offset Programmed corner radius = Actual corner radius + Radius correction value Normal insert nose radius X-axis (+) R Example: Machining an R4.0 corner (with a 0.8 mm nose radius) Programmed corner radius 0.03 R4.07 R4.0 + R0.07 Z-axis (+) S Radius compensation Actual corner radius Normal insert nose radius pro le R4.0 Gouging Radius T correction Nose radius R0.4 0.02 +R0.04 Nose radius R0.8 0.03 +R0.07 Nose radius R1.2 0.08 +R0.18 V ③ Machining program correction for tapers (provided that the correction in step ① has been performed) W Taper turning causes gouging or unmachined surfaces with respect to the programmed tool path. Adjust the tool in the normal direction as shown below. Solid CBN The positive values indicate gouging. Example: Machining 60 and 20 tapers with a 0.8 mm nose radius Ceramic The negative values indicate unmachined surfaces. Taper Angle ( ) Unmachined surface 0.05 mm Wiper nose pro le Gouging 0.08 mm Normal insert nose radius after tool offset Normal direction -25° -20° -15° -10° -5° Nose radius 0.08 0.07 0.05 0.04 0.02 Feed direction Feed direction R0.4 Nose radius 0.09 0.08 0.06 0.05 0.02 :=60° Normal direction R0.8 :=20° Nose radius 0.05 0.05 0.05 0.03 0.02 R1.2 Taper angle ( ) 0° 5° 10° 15° 20° 25° 30° 35° 40° 45° 50° 55° 60° 65° 70° 75° 80° 85° 90° Nose radius 0.00 0.00 0.00 -0.01 -0.01 -0.01 -0.02 -0.02 -0.03 -0.03 -0.04 -0.05 -0.05 -0.05 -0.03 -0.02 -0.02 -0.01 0.00 R0.4 Nose radius 0.00 0.01 0.02 0.03 0.03 0.03 0.03 0.02 0.01 0.00 -0.02 -0.03 -0.05 -0.04 -0.03 -0.02 -0.01 0.00 0.00 R0.8 Nose radius 0.00 0.02 0.04 0.06 0.07 0.08 0.08 0.07 0.06 0.05 0.03 0.00 -0.03 -0.02 -0.01 0.00 0.01 0.00 0.00 R1.2 B19