Каталог Sumitomo токарные резцы (державки) для внутреннего точения - страница 8

Навигация

- E001

- E002

- E003

- E004

- E005

- E006

- E007

- E008

- E009

- E010

- E011

- E012

- E013

- E014

- E015

- E016

- E017

- E018

- E019

- E020

- E021

- E022

- E023

- E024

- E025

- E026

- E027

- E028

- E029

- E030

- E031

- E032

- E033

- E034

- E035

- E036

- E037

- E038

- E039

- E040

- E041

- E042

- E043

- E044

- E045

- E046

- E047

- E048

- E049

- E050

- E051

- E052

- E053

- E054

- E055

- E056

- E057

- E058

- E059

- E060

- E061

- E062

- E063

- E064

- E065

- E066

- E067

- E068

- E069

- E070

- E071

- E072

- E073

- E074

- E075

- E076

- E077

- E078

- E079

- E080

- E081

- E082

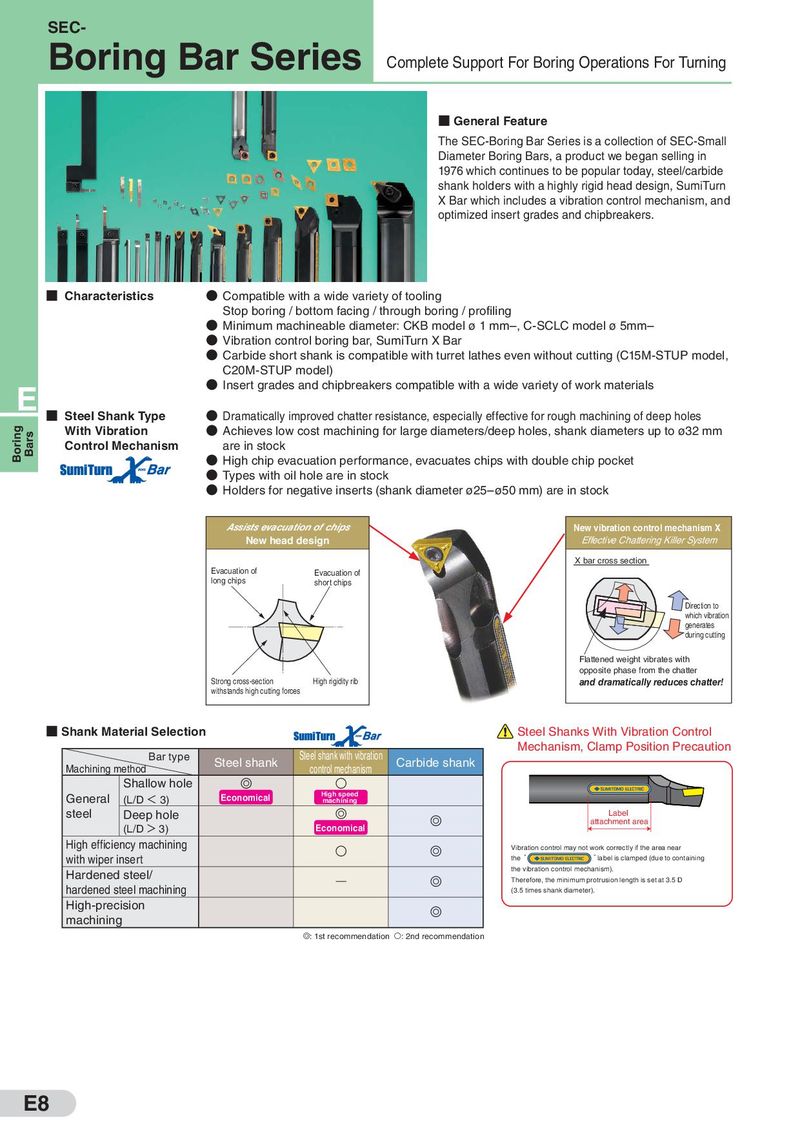

SEC- Boring Bar Series Complete Support For Boring Operations For Turning ■ General Feature The SEC-Boring Bar Series is a collection of SEC-Small Diameter Boring Bars, a product we began selling in 1976 which continues to be popular today, steel/carbide shank holders with a highly rigid head design, SumiTurn X Bar which includes a vibration control mechanism, and optimized insert grades and chipbreakers. ■ Characteristics ● Compatible with a wide variety of tooling Stop boring / bottom facing / through boring / profiling ● Minimum machineable diameter: CKB model ø 1 mm–, C-SCLC model ø 5mm– ● Vibration control boring bar, SumiTurn X Bar ● Carbide short shank is compatible with turret lathes even without cutting (C15M-STUP model, C20M-STUP model) E ● Insert grades and chipbreakers compatible with a wide variety of work materials ■ Steel Shank Type ● Dramatically improved chatter resistance, especially effective for rough machining of deep holes Boring Bars With Vibration ● Achieves low cost machining for large diameters/deep holes, shank diameters up to ø32 mm Control Mechanism are in stock ● High chip evacuation performance, evacuates chips with double chip pocket ● Types with oil hole are in stock ● Holders for negative inserts (shank diameter ø25–ø50 mm) are in stock Assists evacuation of chips New vibration control mechanism X New head design Effective Chattering Killer System X bar cross section Evacuation of Evacuation of long chips short chips Direction to which vibration generates during cutting Flattened weight vibrates with opposite phase from the chatter Strong cross-section High rigidity rib and dramatically reduces chatter! withstands high cutting forces ■ Shank Material Selection Steel Shanks With Vibration Control Bar type Steel shank with vibration Mechanism, Clamp Position Precaution Machining method Steel shank control mechanism Carbide shank Shallow hole G S General (L/D < 3) Economical High speed machining steel Deep hole G G Label (L/D > 3) Economical attachment area High efficiency machining S G Vibration control may not work correctly if the area near with wiper insert the label is clamped (due to containing Hardened steel/ the vibration control mechanism). Q G Therefore, the minimum protrusion length is set at 3.5 D hardened steel machining (3.5 times shank diameter). High-precision G machining G: 1st recommendation S: 2nd recommendation E8

Каталог Sumitomo монолитные фрезы

Каталог Sumitomo монолитные фрезы Каталог Sumitomo твердосплавные заготовки

Каталог Sumitomo твердосплавные заготовки Каталог Sumitomo токарные резцы (державки) для наружного точения

Каталог Sumitomo токарные резцы (державки) для наружного точения Каталог Sumitomo пластины с кубическим нитридом бора Sumiboron

Каталог Sumitomo пластины с кубическим нитридом бора Sumiboron Общий каталог Sumitomo 2019 - 2020

Общий каталог Sumitomo 2019 - 2020