Каталог Sumitomo токарные резцы (державки) для внутреннего точения - страница 5

Навигация

- E001

- E002

- E003

- E004

- E005

- E006

- E007

- E008

- E009

- E010

- E011

- E012

- E013

- E014

- E015

- E016

- E017

- E018

- E019

- E020

- E021

- E022

- E023

- E024

- E025

- E026

- E027

- E028

- E029

- E030

- E031

- E032

- E033

- E034

- E035

- E036

- E037

- E038

- E039

- E040

- E041

- E042

- E043

- E044

- E045

- E046

- E047

- E048

- E049

- E050

- E051

- E052

- E053

- E054

- E055

- E056

- E057

- E058

- E059

- E060

- E061

- E062

- E063

- E064

- E065

- E066

- E067

- E068

- E069

- E070

- E071

- E072

- E073

- E074

- E075

- E076

- E077

- E078

- E079

- E080

- E081

- E082

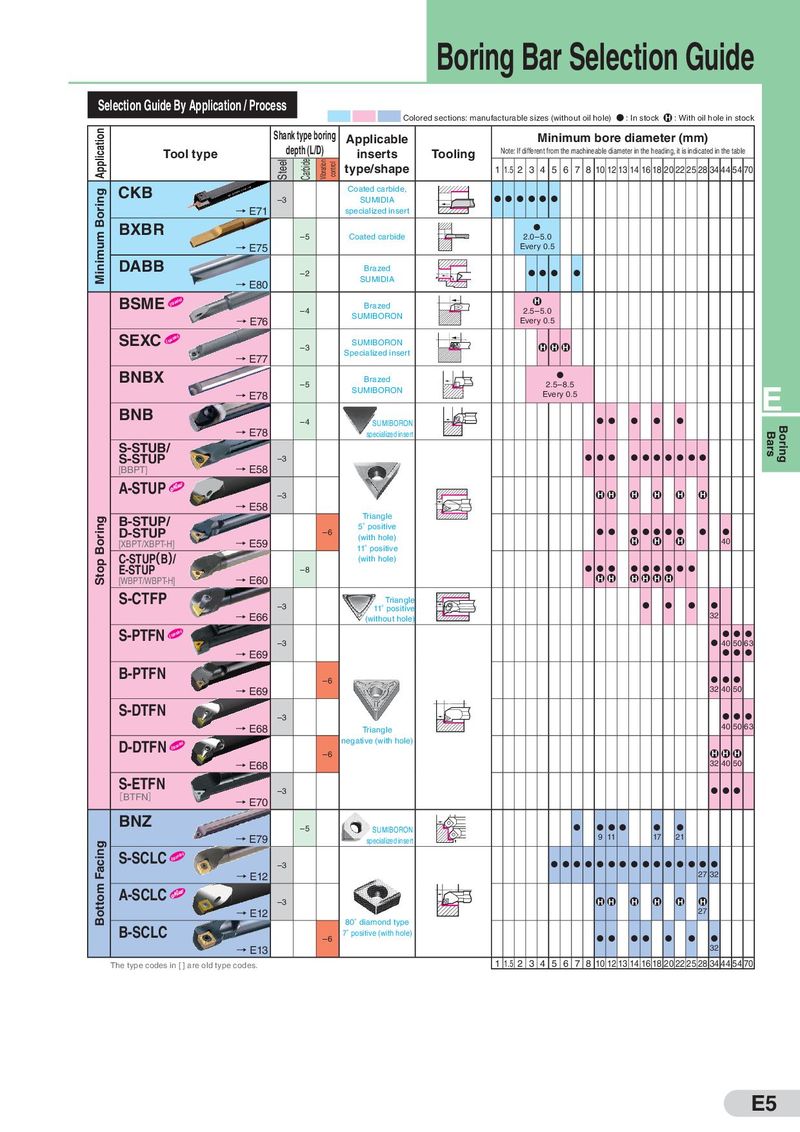

Boring Bar Selection Guide Selection Guide By Application / Process Colored sections: manufacturable sizes (without oil hole) ● : In stock H : With oil hole in stock Application Shank type boring Applicable Minimum bore diameter (mm) Tool type depth (L/D) inserts Tooling Note: If different from the machineable diameter in the heading, it is indicated in the table Steel Carbide Vibration control type/shape 1 1.5 2 3 4 5 6 7 8 10 12 13 14 16 18 20 22 25 28 34 44 54 70 Minimum Boring CKB Coated carbide, –3 SUMIDIA D D D D D D → E71 specialized insert BXBR D –5 Coated carbide 2.0–5.0 → E75 Every 0.5 DABB –2 Brazed D D D D → E80 SUMIDIA BSME Expanded Brazed H –4 SUMIBORON 2.5–5.0 → E76 Every 0.5 SEXC Expanded SUMIBORON –3 Specialized insert H H H → E77 BNBX Brazed D –5 SUMIBORON 2.5–8.5 E → E78 Every 0.5 BNB –4 SUMIBORON D D D D D → E78 specialized insert Bars Boring S-STUB/ S-STUP –3 D D D D D D D D D D [BBPT] → E58 A-STUP –3 H H H H H H → E58 Stop Boring B-STUP/ Triangle D-STUP –6 5 positive D D D D D D D D D [XBPT/XBPT-H] → E59 (with hole) H H H 40 11 positive C-STUP(B)/ (with hole) E-STUP –8 D D D D D D D D D [WBPT/WBPT-H] → E60 H H H H H H S-CTFP –3 Triangle D D D D 11 positive 32 → E66 (without hole) S-PTFN Expanded D D D –3 D 40 50 63 → E69 D D D B-PTFN –6 D D D → E69 32 40 50 S-DTFN –3 D D D → E68 Triangle 40 50 63 D-DTFN Expanded negative (with hole) –6 H H H → E68 32 40 50 S-ETFN –3 D D D [BTFN] → E70 BNZ –5 SUMIBORON D D D D D D Bottom Facing → E79 specialized insert 9 11 17 21 S-SCLC Expanded –3 D D D D D D D D D D D D D D D → E12 27 32 A-SCLC –3 H H H H H H → E12 27 B-SCLC 80 diamond type –6 7 positive (with hole) D D D D D D D → E13 32 The type codes in [ ] are old type codes. 1 1.5 2 3 4 5 6 7 8 10 12 13 14 16 18 20 22 25 28 34 44 54 70 E5

Каталог Sumitomo монолитные фрезы

Каталог Sumitomo монолитные фрезы Каталог Sumitomo твердосплавные заготовки

Каталог Sumitomo твердосплавные заготовки Каталог Sumitomo токарные резцы (державки) для наружного точения

Каталог Sumitomo токарные резцы (державки) для наружного точения Каталог Sumitomo пластины с кубическим нитридом бора Sumiboron

Каталог Sumitomo пластины с кубическим нитридом бора Sumiboron Общий каталог Sumitomo 2019 - 2020

Общий каталог Sumitomo 2019 - 2020