Каталог Sumitomo токарные резцы (державки) для внутреннего точения - страница 75

Навигация

- E001

- E002

- E003

- E004

- E005

- E006

- E007

- E008

- E009

- E010

- E011

- E012

- E013

- E014

- E015

- E016

- E017

- E018

- E019

- E020

- E021

- E022

- E023

- E024

- E025

- E026

- E027

- E028

- E029

- E030

- E031

- E032

- E033

- E034

- E035

- E036

- E037

- E038

- E039

- E040

- E041

- E042

- E043

- E044

- E045

- E046

- E047

- E048

- E049

- E050

- E051

- E052

- E053

- E054

- E055

- E056

- E057

- E058

- E059

- E060

- E061

- E062

- E063

- E064

- E065

- E066

- E067

- E068

- E069

- E070

- E071

- E072

- E073

- E074

- E075

- E076

- E077

- E078

- E079

- E080

- E081

- E082

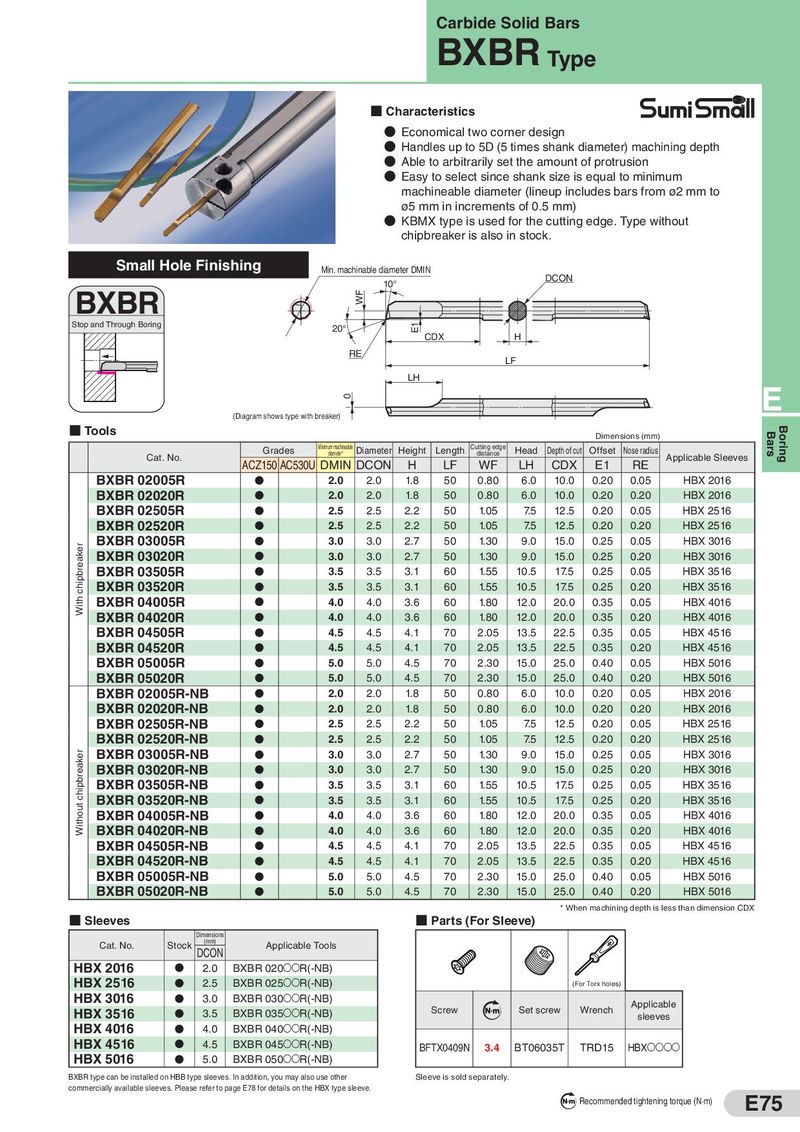

Carbide Solid Bars BXBR Type ■ Characteristics ● Economical two corner design ● Handles up to 5D (5 times shank diameter) machining depth ● Able to arbitrarily set the amount of protrusion ● Easy to select since shank size is equal to minimum machineable diameter (lineup includes bars from ø2 mm to ø5 mm in increments of 0.5 mm) ● KBMX type is used for the cutting edge. Type without chipbreaker is also in stock. Small Hole Finishing Min. machinable diameter DMIN 10° DCON BXBR WF Stop and Through Boring 20° E1 CDX H RE LF LH 0 E (Diagram shows type with breaker) ■ Tools Dimensions (mm) Bars Boring Grades Minimum machineable Diameter Height Length Cutting edge Head Depth of cut Offset Nose radius Cat. No. diameter* distance Applicable Sleeves ACZ150 AC530U DMIN DCON H LF WF LH CDX E1 RE BXBR 02005R D 2.0 2.0 1.8 50 0.80 6.0 10.0 0.20 0.05 HBX 2016 BXBR 02020R D 2.0 2.0 1.8 50 0.80 6.0 10.0 0.20 0.20 HBX 2016 BXBR 02505R D 2.5 2.5 2.2 50 1.05 7.5 12.5 0.20 0.05 HBX 2516 BXBR 02520R D 2.5 2.5 2.2 50 1.05 7.5 12.5 0.20 0.20 HBX 2516 With chipbreaker BXBR 03005R D 3.0 3.0 2.7 50 1.30 9.0 15.0 0.25 0.05 HBX 3016 BXBR 03020R D 3.0 3.0 2.7 50 1.30 9.0 15.0 0.25 0.20 HBX 3016 BXBR 03505R D 3.5 3.5 3.1 60 1.55 10.5 17.5 0.25 0.05 HBX 3516 BXBR 03520R D 3.5 3.5 3.1 60 1.55 10.5 17.5 0.25 0.20 HBX 3516 BXBR 04005R D 4.0 4.0 3.6 60 1.80 12.0 20.0 0.35 0.05 HBX 4016 BXBR 04020R D 4.0 4.0 3.6 60 1.80 12.0 20.0 0.35 0.20 HBX 4016 BXBR 04505R D 4.5 4.5 4.1 70 2.05 13.5 22.5 0.35 0.05 HBX 4516 BXBR 04520R D 4.5 4.5 4.1 70 2.05 13.5 22.5 0.35 0.20 HBX 4516 BXBR 05005R D 5.0 5.0 4.5 70 2.30 15.0 25.0 0.40 0.05 HBX 5016 BXBR 05020R D 5.0 5.0 4.5 70 2.30 15.0 25.0 0.40 0.20 HBX 5016 BXBR 02005R-NB D 2.0 2.0 1.8 50 0.80 6.0 10.0 0.20 0.05 HBX 2016 BXBR 02020R-NB D 2.0 2.0 1.8 50 0.80 6.0 10.0 0.20 0.20 HBX 2016 BXBR 02505R-NB D 2.5 2.5 2.2 50 1.05 7.5 12.5 0.20 0.05 HBX 2516 BXBR 02520R-NB D 2.5 2.5 2.2 50 1.05 7.5 12.5 0.20 0.20 HBX 2516 Without chipbreaker BXBR 03005R-NB D 3.0 3.0 2.7 50 1.30 9.0 15.0 0.25 0.05 HBX 3016 BXBR 03020R-NB D 3.0 3.0 2.7 50 1.30 9.0 15.0 0.25 0.20 HBX 3016 BXBR 03505R-NB D 3.5 3.5 3.1 60 1.55 10.5 17.5 0.25 0.05 HBX 3516 BXBR 03520R-NB D 3.5 3.5 3.1 60 1.55 10.5 17.5 0.25 0.20 HBX 3516 BXBR 04005R-NB D 4.0 4.0 3.6 60 1.80 12.0 20.0 0.35 0.05 HBX 4016 BXBR 04020R-NB D 4.0 4.0 3.6 60 1.80 12.0 20.0 0.35 0.20 HBX 4016 BXBR 04505R-NB D 4.5 4.5 4.1 70 2.05 13.5 22.5 0.35 0.05 HBX 4516 BXBR 04520R-NB D 4.5 4.5 4.1 70 2.05 13.5 22.5 0.35 0.20 HBX 4516 BXBR 05005R-NB D 5.0 5.0 4.5 70 2.30 15.0 25.0 0.40 0.05 HBX 5016 BXBR 05020R-NB D 5.0 5.0 4.5 70 2.30 15.0 25.0 0.40 0.20 HBX 5016 * When machining depth is less than dimension CDX ■ Sleeves ■ Parts (For Sleeve) Dimensions Cat. No. Stock (mm) Applicable Tools DCON HBX 2016 D 2.0 BXBR 020SSR(-NB) HBX 2516 D 2.5 BXBR 025SSR(-NB) (For Torx holes) HBX 3016 D 3.0 BXBR 030SSR(-NB) Applicable HBX 3516 D 3.5 BXBR 035SSR(-NB) Screw Set screw Wrench sleeves HBX 4016 D 4.0 BXBR 040SSR(-NB) HBX 4516 D 4.5 BXBR 045SSR(-NB) BFTX0409N 3.4 BT06035T TRD15 HBXSSSS HBX 5016 D 5.0 BXBR 050SSR(-NB) BXBR type can be installed on HBB type sleeves. In addition, you may also use other Sleeve is sold separately. commercially available sleeves. Please refer to page E78 for details on the HBX type sleeve. Recommended tightening torque (N·m) E75

Каталог Sumitomo монолитные фрезы

Каталог Sumitomo монолитные фрезы Каталог Sumitomo твердосплавные заготовки

Каталог Sumitomo твердосплавные заготовки Каталог Sumitomo токарные резцы (державки) для наружного точения

Каталог Sumitomo токарные резцы (державки) для наружного точения Каталог Sumitomo пластины с кубическим нитридом бора Sumiboron

Каталог Sumitomo пластины с кубическим нитридом бора Sumiboron Общий каталог Sumitomo 2019 - 2020

Общий каталог Sumitomo 2019 - 2020