Каталог Sumitomo токарные резцы (державки) для внутреннего точения - страница 77

Навигация

- E001

- E002

- E003

- E004

- E005

- E006

- E007

- E008

- E009

- E010

- E011

- E012

- E013

- E014

- E015

- E016

- E017

- E018

- E019

- E020

- E021

- E022

- E023

- E024

- E025

- E026

- E027

- E028

- E029

- E030

- E031

- E032

- E033

- E034

- E035

- E036

- E037

- E038

- E039

- E040

- E041

- E042

- E043

- E044

- E045

- E046

- E047

- E048

- E049

- E050

- E051

- E052

- E053

- E054

- E055

- E056

- E057

- E058

- E059

- E060

- E061

- E062

- E063

- E064

- E065

- E066

- E067

- E068

- E069

- E070

- E071

- E072

- E073

- E074

- E075

- E076

- E077

- E078

- E079

- E080

- E081

- E082

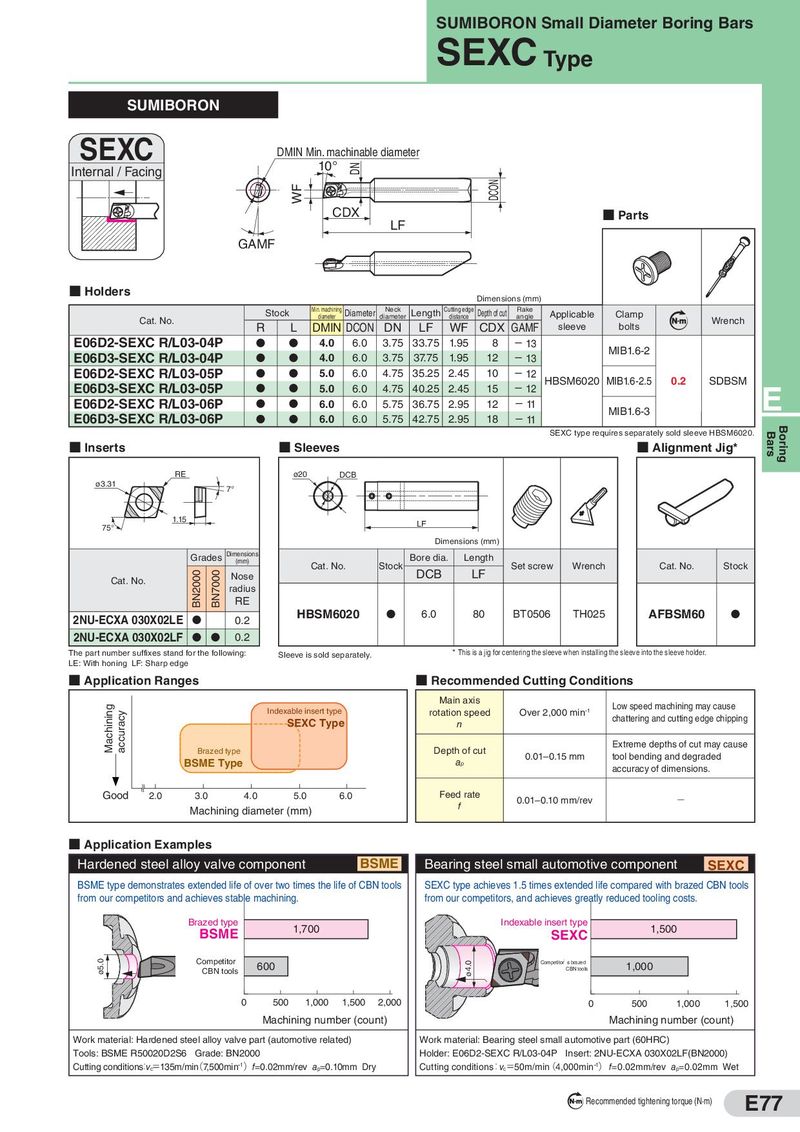

SUMIBORON Small Diameter Boring Bars SEXC Type SUMIBORON SEXC DMIN Min. machinable diameter Internal / Facing 10° DN WF DCON CDX ■ Parts LF GAMF ■ Holders Dimensions (mm) Stock Min. machining Diameter Neck Length Cutting edge Depth of cut Rake Applicable Clamp Cat. No. diameter diameter distance angle Wrench R L DMIN DCON DN LF WF CDX GAMF sleeve bolts E06D2-SEXC R/L03-04P D D 4.0 6.0 3.75 33.75 1.95 8 − 13 MIB1.6-2 E06D3-SEXC R/L03-04P D D 4.0 6.0 3.75 37.75 1.95 12 − 13 E06D2-SEXC R/L03-05P D D 5.0 6.0 4.75 35.25 2.45 10 − 12 HBSM6020 MIB1.6-2.5 0.2 SDBSM E06D3-SEXC R/L03-05P D D 5.0 6.0 4.75 40.25 2.45 15 − 12 E E06D2-SEXC R/L03-06P D D 6.0 6.0 5.75 36.75 2.95 12 − 11 MIB1.6-3 E06D3-SEXC R/L03-06P D D 6.0 6.0 5.75 42.75 2.95 18 − 11 SEXC type requires separately sold sleeve HBSM6020. Bars Boring ■ Inserts ■ Sleeves ■ Alignment Jig* RE ø20 DCB ø3.31 7° 1.15 LF 75° Dimensions (mm) Grades Dimensions Bore dia. Length (mm) Cat. No. Stock Set screw Wrench Cat. No. Stock Cat. No. BN2000 BN7000 Nose DCB LF radius RE 2NU-ECXA 030X02LE D 0.2 HBSM6020 D 6.0 80 BT0506 TH025 AFBSM60 D 2NU-ECXA 030X02LF D D 0.2 The part number suffixes stand for the following: Sleeve is sold separately. * This is a jig for centering the sleeve when installing the sleeve into the sleeve holder. LE: With honing LF: Sharp edge ■ Application Ranges ■ Recommended Cutting Conditions Machining Main axis Low speed machining may cause accuracy Indexable insert type rotation speed Over 2,000 min-1 chattering and cutting edge chipping SEXC Type n Brazed type Depth of cut Extreme depths of cut may cause BSME Type ap 0.01–0.15 mm tool bending and degraded accuracy of dimensions. Good 2.0 3.0 4.0 5.0 6.0 Feed rate 0.01–0.10 mm/rev − Machining diameter (mm) f ■ Application Examples Hardened steel alloy valve component BSME Bearing steel small automotive component SEXC BSME type demonstrates extended life of over two times the life of CBN tools SEXC type achieves 1.5 times extended life compared with brazed CBN tools from our competitors and achieves stable machining. from our competitors, and achieves greatly reduced tooling costs. Brazed type 1,700 Indexable insert type 1,500 BSME SEXC ø5.0 Competitor 600 ø4.0 Competitor s brazed 1,000 CBN tools CBN tools 0 500 1,000 1,500 2,000 0 500 1,000 1,500 Machining number (count) Machining number (count) Work material: Hardened steel alloy valve part (automotive related) Work material: Bearing steel small automotive part (60HRC) Tools: BSME R50020D2S6 Grade: BN2000 Holder: E06D2-SEXC R/L03-04P Insert: 2NU-ECXA 030X02LF(BN2000) Cutting conditions:vc=135m/min(7,500min-1)f=0.02mm/rev ap=0.10mm Dry Cutting conditions:vc=50m/min(4,000min-1) f=0.02mm/rev ap=0.02mm Wet Recommended tightening torque (N·m) E77

Каталог Sumitomo монолитные фрезы

Каталог Sumitomo монолитные фрезы Каталог Sumitomo твердосплавные заготовки

Каталог Sumitomo твердосплавные заготовки Каталог Sumitomo токарные резцы (державки) для наружного точения

Каталог Sumitomo токарные резцы (державки) для наружного точения Каталог Sumitomo пластины с кубическим нитридом бора Sumiboron

Каталог Sumitomo пластины с кубическим нитридом бора Sumiboron Общий каталог Sumitomo 2019 - 2020

Общий каталог Sumitomo 2019 - 2020