Основной каталог Kyocera 2021 - 2022 - страница 979

Навигация

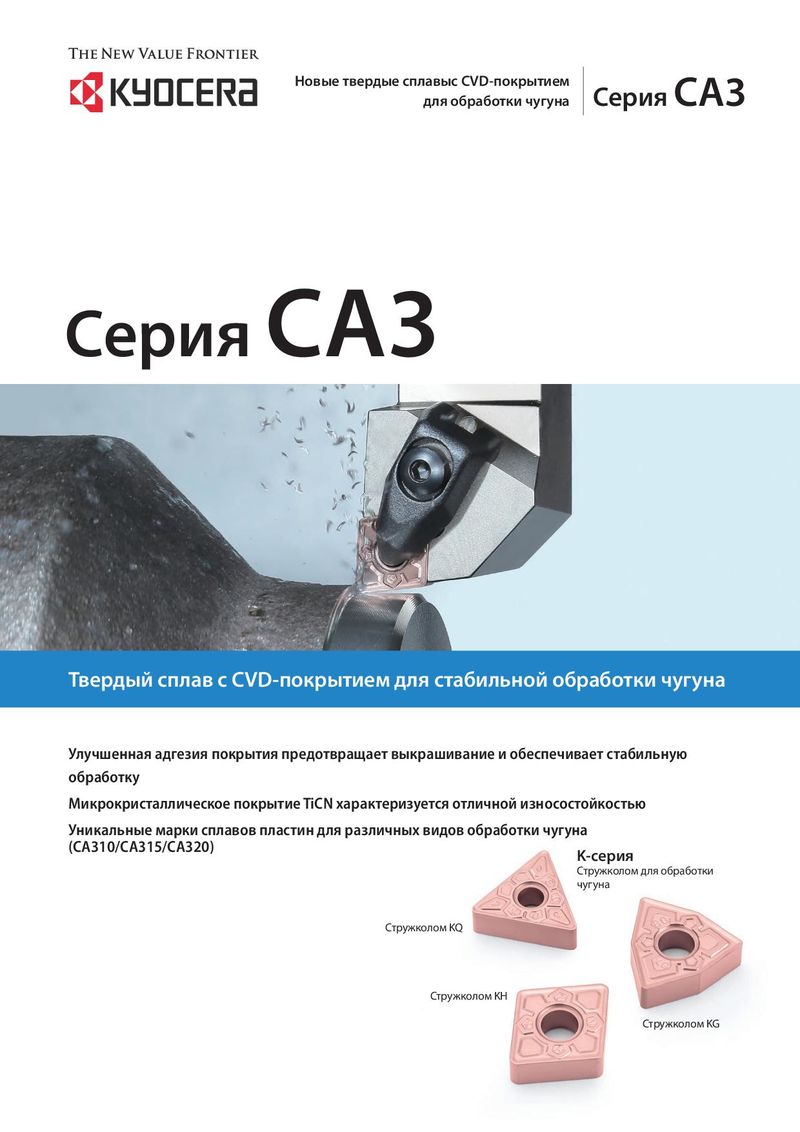

Каталог Kyocera пластины с CVD покрытием для обработки чугуна

Каталог Kyocera пластины с CVD покрытием для обработки чугуна Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA Каталог Kyocera фрезы MRX с позитивными круглыми пластинами

Каталог Kyocera фрезы MRX с позитивными круглыми пластинами Каталог Kyocera пластины с CVD покрытием для обработки стали

Каталог Kyocera пластины с CVD покрытием для обработки стали - Cover

- Chapter Overview

- Contents

- Introduction

- Introduction

- Negative-Chipbreaker

- Positive-Chipbreaker

- Page Guide

- Cermet / coated carbide / carbide lineup

- Negative inserts 80° Rhombic

- 55° Rhombic

- 55° Parallelogramm

- Round

- 90° Square

- 90° Square

- 60° Triangle

- 35° Rhombic

- 80° Trigon

- Small double sided tools

- 80° Rhombic

- 55° Rhombic

- 55° Rhombic

- 70° Rhombic

- Round

- 90° Square

- 90° Square

- 60° Triangle

- 60° Triangle

- 35° Rhombic

- 35° Rhombic

- 80° Trigon

- Bearing machining Round / Square-Type

- Inserts for back turning TKFB

- ABS / ABW

- Ceramic lineup

- Negative inserts 80° Rhombic

- 55° Rhombic

- 75° Rhombic

- Round

- 90° Square

- 60° Triangle

- 35° Rhombic

- Positive inserts Round

- Square

- Triangle

- Inserts for high hardened roll

- Grooving inserts

- CBN Lineup

- Introduction

- Solid bar EZB-NB

- GMN

- GDGS

- Grooving inserts GBA

- 80° Trigon

- 35° Rhombic

- 60° Triangle

- 55° Rhombic

- Positive inserts 80° Rhombic

- 60° Triangle / Solid

- 90° Square / Solid

- Round / Solid

- 80° Rhombic / Solid

- 80° Trigon

- 35° Rhombic

- 60° Triangle

- 90° Square

- 55° Rhombic

- Negative inserts 80° Rhombic

- PCD Lineup

- Introduction

- Milling inserts Available inserts

- VNBR-NB

- VNGR-NB

- Solid bar EZB-NB

- TKF

- GMGW

- GMN

- GDGS

- GV/GVF

- Grooving inserts GBA/TGF

- 80° Trigon

- 35° Rhombic

- 60° Triangle

- 90° Square

- 55° Rhombic

- Positive inserts 80° Rhombic

- 80° Trigon

- 35° Rhombic

- 60° Triangle

- 55° Rhombic

- Negative inserts 80° Rhombic

- Introduction

- Toolholders for general purpose

- CN insert DCLN/DCLN-JCT/PCLN

- DN insert DDJN/DDJN-JCT/DDHN

- PDJN/PDHN

- SN insert DSBN/PSBN/PSKN

- PSSN/PSDN

- TN insert DTGN/PTGN/PTFN

- WTJN/WTKN/WTEN

- VN insert DVLN/DVPN/DVVN

- MVLN/MVVN

- PVLN/PVPN/PVVN

- RC insert PRGC/PRXC

- RN insert PRGN

- WN Insert DWLN/DWLN-JCT/PWLN/WWLN

- Toolholders for ceramic inserts

- Selection guide for ceramic inserts

- RN insert CRSN/CRDN

- SN insert CSRN/CS-N/CSKN/CSYN/CSSN/CSDN

- EN insert CELN

- DN insert CDJN

- CN insert CCLN

- TN insert CTJN/CTUN

- Toolholders for CBN inserts

- CNMN insert CCRN-A/CCLN-A

- RNMN insert CRSN-A/CRDN-A

- SNMN insert CSRN-A/CSKN-A/CSSN-A/CSDN-A

- TNMN insert CTJN-A/CTUN-A

- Toolholders for bearing machining

- RCMT insert PRGC-BE

- SNMF insert CBSN

- Recommended cutting conditions

- Introduction

- Toolholders for back turning

- TKFB insert TKFB

- KTKF / KTKF Goose-neck holder

- ABS15 insert AABS-40F/SABS-40F

- ABW15 insert AABW-40F/SABW-40F

- ABW23 insert AABW-50F/SABW-50F

- Goose-neck toolholders

- DC insert SDJC

- VP insert SVLP

- External toolholders

- CC insert ACLC-FF

- SCLC

- SCLC-FF/SCLC-FFJCT

- DC insert ADJC-FF

- SDJC-FF

- SDJC-FFJCT

- SDJC

- SDLC-FF

- SDXC

- SDNC-F

- SDNC

- DP insert SDLP-FF

- TC/TP insert STGC

- STGP

- VB/VC insert AVJB-FF/SVJB-FF/SVJB-FFJCT/SVJB/SVPB/SVVB

- SVJC-FF/SVLC-FF

- SVPC-FF/SVVC

- VP insert SVJP-FF/SVJP-FFJCT/SVLP-FF/SVPP-FF

- External sleeve holders

- CC insert S...SCLC

- DC insert S...SDUC/S...SDLC

- VB/VC insert S...SVUB/S...SVUC

- Toolholders for small double sided tooling

- CN insert SCLN-FF (without offset)

- DN insert SDLN-FF (without offset)

- TN insert STLN-FF (without offset)

- Toolholders for double sided tooling for automatic lathes

- CN insert PCLN-FF (without offset)

- TN insert PTLN-FF (without offset)

- Recommended cutting conditions

- Introduction

- Solid tip bars for micro boring

- System Tip-Bars VNB type

- VNBX-S

- TWB

- STW/S-STW

- TWBT

- Dynamic-Bars

- CC insert A/S-SCLC-AE

- CP insert A-SCLP-AE

- DC insert A-SDUC-AE

- JC insert C-SJLC

- TC insert A-STLC-AE

- TB/TP insert S-STLB-AE

- VB/VC/VP insert A-SVJP-AE/A-SVJC-AE/A-SVJB-AE

- WB/WP insert S-SWUB-AE/A-SWUP-AE

- Borings bars (screw clamp / top clamp)

- SP insert S-SSKP/S-CSKP

- TP insert S-CTUP

- Bearing machining

- RPMT insert SRCP-B

- SNMF insert CBSN-B

- AD Bars

- CN insert HA-PCLN

- DN insert HA-PDUN

- TN insert HA-PTFN

- CC insert HA-SCLC

- DC insert HA-SDUC

- Boring adapter for AD Bars AD type with dampener system

- Boring bars for negative type inserts

- CN insert A-DCLN

- DN insert S-PDUN/A-PDUN (11)

- SN insert A-DSKN

- TN insert A-DTFN

- WN insert S-PWLN/A-PWLN

- Boring bars for ceramic inserts

- Boring bars for CBN inserts

- Technical information

- Applicable sleeves

- Introduction

- External grooving

- GBA type GBA

- KGB/KGBS

- GBF-KGBF-JCT

- TGF type TGF

- S-KGBF

- KTGF-F/KTGF/S-KTGF

- KGD

- KGD-JCT (Integral type)

- KGD (Integral type for automatic lathes)

- KGD (Integral type)

- KGDF S separate type

- GMGW type GMGW

- GH/GHU/GA type GH/GHU/GA

- GM/GMN/GMM/GMG/GMGA/FGG type GM/GMN/GMM/GMG/GMGA/FGG

- Internal grooving

- KGIA

- GIA type GIA

- GMM/GMG/GMGA type GMM/GMG/GMGA

- GH/GHU type GH/GHU

- GBA type KIGBA

- GDM type GDM

- GV type GV

- SIGE-WH-90 carbide shank bar (for automatic lathe; with coolant hole)

- SIGE-WH carbide shank bar (with coolant hole)

- SIGE-EH Excellent Bar (with coolant hole)

- GE/GER type GE/GER

- GC type GC

- VNG type VNG

- GMM

- Face grooving

- KGDF-Z (Integral type)

- GDFM/GDFMS type GDFM/GDMFS

- TWFG/TWFGT small diameter face grooving (Twin-Bars) TWFG

- VNFG type VNFG

- KGDF 0° separate type

- KGDF 90 separate type

- FTK type FTK

- GMM/GMG/GMGA type GMM/GMG/GMGA

- FMM/FMN type FMM/FMN

- GIFV (A/B/C)

- GFV\AA

- GVF type GVF

- Grooving

- Introduction

- Small diameter cut-off

- TKF type TKF

- KTKF

- KTKF-JCT

- KTKFS

- TKFS type TKFS

- KTKF-S

- KGD type

- GDM/GDMS/GDG type GDM/GDMS/GDG

- KGD (Integral type for automatic lathe)

- KGDS (for sub spindle tooling)

- KGD-JCT (Integral type)

- KGD (Integral type)

- KGD-JCT (Integral type for automatic lathe)

- KGD-JCT

- KGDS separate type

- KGM type

- GMM/GMN/GMR/GML type GMM/GMN/GMR/GMLw

- KGM/KGM-T/KGMM/KGMS

- 1-edge cut-off inserts

- TKN/TK type TKN/TK

- KTKB-SS/KTKB-S

- Toolblocks

- KTKH-S (Integral type)

- Introduction

- Threading inserts

- Metric External threading / 60° full profile

- Internal threading / 60° full profile

- Unified External threading / 60° full profile

- Internal threading / 60° full profile

- Parallel pipe, Whitworth External threading

- Internal threading

- Tapered pipe External threading / 55° full profile

- Internal threading / 55° full profile

- American national tapered pipe External threading

- Internal threading

- 60° type (Partial profile/M, UN) External threading

- Internal threading

- 55° type (Partial profile/G, R, Rc, W) External threading

- Internal threading

- 30° type (Trapezoidal) External threading

- Internal threading

- Threading toolholders

- External toolholders KTN/KTNS/KTN-JCT

- S-KTN

- Internal toolholders SIN/CIN

- Multipurpose threading tools

- TKFT for small parts machining TKFT

- KTKF

- TTX for small parts machining TTX

- KTTX/S-KTTX

- TT for external and internal threading TT

- KTT (external)

- KITG (internal)

- System Bar for micro internal threading VNT

- TPGB for internal threading TPGB

- S-STWP/S-STWP-E

- Recommended cutting conditions

- Depth of cut and number of passes

- Applicable toolholders and inserts

- Threading methods

- Threading methods and basic profiles

- Thread types

- Introduction

- MagicDrill DRA

- SF-DRA 12 DC

- SF-DRA 8 DC

- SF-DRA 5 DC

- SF-DRA 3 DC

- Flanged shank SF SF-DRA 1.5 DC

- Chamfering attachment for SS-DRA CH\-DRA

- SS-DRA 8 DC

- SS-DRA 5 DC

- SS-DRA 3 DC

- Straight shank SS SS-DRA 1.5 DC

- Recommended cutting conditions

- MagicDrill DRC

- Straight shank SS SS-DRC 3 DC

- SS-DRC 5 DC

- SS-DRC 8 DC

- Chamfering attachment for SS-DRC CH\-DRC

- Flanged shank SF SF-DRC 3 DC

- SF-DRC 5 DC

- SF-DRC 8 DC

- Recommended cutting conditions

- MagicDrill DRV

- Chamfering attachment for DRV CH\-DRV

- DRV 6 DC

- DRV 5 DC

- DRV 4 DC

- DRV 3 DC

- Toolholder DRV DRV 2 DC

- Recommended cutting conditions

- Adjustable sleeve (DRV/DRZ/DRX)

- MagicDrill DRZ

- Toolholder DRZ DRZ 2 DC

- DRZ 3 DC

- DRZ-CR

- Recommended cutting conditions

- MagicDrill DRS

- MagicDrill DRX

- Trouble shooting (DRV / DRX / DRZ / DRX)

- Lathe installation DRX/DRZ

- MagicDrill DRW

- Introduction

- Introduction

- ISO identification

- MFPN Series MFPN66

- MFK / MFK-SF

- MOF45 OFMT

- Lead angle 15°

- MSRS15 SPMT

- Lead angle 0°/ 2°

- MEW LOMU/LOGT

- MEC/MECX BDGT/BDMT

- MEWH LOMU/LOGT

- MEV TOMT

- MECH/MECHT BDMT

- MECH/MECHT MECHT

- MFWN WNEU/WNMU/WNGT

- MFSN88 SNMU

- MFLN90 LOGU

- MSRS90 SPMT

- MSR / MSR-BT50 APMT

- DMC/DMC-SX/DMC-H NDCT/NDCW/NDMM

- MFAH ENET

- MEAS KCGT

- High feed cutter

- MFH Series SOMT/LOGU/LPGT

- MFH Series MFH Mini

- MFH Series MFH Micro

- Multi-Function end mill

- Applicable inserts GOMT/JOMT

- Slott mill

- Ball-nose / radius type cutters

- MRF/MRFW RDFG

- MRW ROMU

- MRX RDMT/RDGT/RPMT/RPGT

- Other applications

- MCSE (chamfering end mill)

- Square-type inserts MEF (bolt countersink end mill)

- S type inserts METS (T-Slot mill)

- MVG (ring grooving end milll for M/C)

- GVR/GVFR

- MGI (grooving end mill for M/C)

- Grooving GVR/GVFR

- Other inserts

Ball-nose / radius type cutters MRX Recommended cutting conditions Recommended chipbreaker (fz: mm/t) Recommended insert grades (Vc: m/min) * RD**08 type: ap=2mm, RP**10 type: ap=2.5mmWorkpiece materialRP**12 type: ap=3mm, RP**16 type: ap=4mmMEGACOAT NANO CVD Coated carbide RDMT-GMRPMT-GM RDGT-GMRPGT-GM RDGT-SMRPGT-SM RDMT-GHRPMT-GH PR1535 PR1525 PR1510 CA6535 Carbon steel ★ ✩ ✩ ✩ ✩ ★0.1~0.2~0.30.1~0.2~0.30.06~0.15~0.20.15~0.3~0.35120~180~250120~180~250-- Alloy steel ★ ✩ ✩ ✩ ✩ ★0.1~0.2~0.30.1~0.2~0.30.06~0.15~0.20.15~0.3~0.35100~160~220100~160~220-- Mold steel ★ ✩ ✩ ✩ ✩ ★0.1~0.15~0.250.1~0.15~0.250.06~0.12~0.20.15~0.2~0.380~140~18080~140~180-- Stainless steel (Austenitic related) ✩ ✩ ★ ✩ ★ ✩0.1~0.15~0.20.1~0.15~0.20.06~0.12~0.20.15~0.3~0.25100~160~200100~160~200-- Stainless steel (Martensitic related) ✩ ✩ ★ ✩ ✩0.1~0.15~0.20.1~0.15~0.20.06~0.12~0.20.15~0.2~0.25150~200~250--★180~240~300 Stainless steel (Precipitation Hardening) ✩0.1~0.15~0.2 ★ ✩ ✩0.1~0.15~0.20.06~0.12~0.20.15~0.2~0.25★90~120~150- - - Gray cast iron ★ ✩0.1~0.2~0.30.1~0.2~0.3- ✩0.15~0.3~0.35 - - ★120~180~250 - Nodular cast iron ★ ✩0.1~0.15~0.250.1~0.15~0.25- ✩0.15~0.2~0.3 - - ★100~150~200 - Ni-base heat-resistant alloys ✩ ★ ✩ ✩ ✩0.1~0.12~0.150.1~0.12~0.150.06~0.1~0.150.12~0.15~0.220~30~50--★20~30~50 Titanium alloys ✩ ✩ ★0.1~0.12~0.150.1~0.12~0.150.06~0.1~0.15-★40~60~80 - ✩30~50~70 - * Machining with coolant is recommended for Ni-base heat-resistant alloys and titanium alloys. ★: 1st Recommendation ✩: 2nd Recommendation * RDGT/RPGT are recommended for stainless steel, Ni-base heat-resistant alloys and titanium alloy. * The bold-faced number indicates a center value of recommended cutting condition. Adjust the cutting speed and the feed rate within the above conditions according to the actual machining situation. * Recommended feed rate in the table is the reference value when ap is RE/2. (2 mm for RD**08/2.5 mm for RP**10/3mm for RP**12/4 mm for RP**16) For other ap, calculate the recommended feed rate based on the conversion factor below. * For MRX16-S16-08-2T(-160), MRX16-W-08-2T, MRX20-S20-10-2T(-180) and MRX20-W20-10-2T, set the feed rate not higher than 50% of the recommended cutting conditions. Conversion factor for feed per tooth by depth of cut (ap) Conversion factor for feed per tooth fz Insert Max. ap ap=0.5 mm ap=1 mm ap=1.5 mm ap=2 mm ap=2.5 mm ap=3 mm ap=4 mm ap=5 mm ap=6 mm ap=8 mm RD**08 type (GM/SM/GH chipbreaker) 4mm 1.7 1.3 1.1 1(Standard) 0.9 0.8 0.8 - - - RP**10 type (GM/SM/GH chipbreaker) 5mm 1.9 1.4 1.2 1 1(Standard) 0.9 0.8 0.8 - - RP**12 type (GM/SM/GH chipbreaker) 6mm 2.1 1.5 1.3 1.1 1 1(Standard) 0.9 0.8 0.8 - M RP**16 type (GM/SM/GH chipbreaker) 8mm 2.4 1.7 1.4 1.3 1.1 1.1 1(Standard)0.9 0.8 0.8 * Example (ROMU12 type, carbon steel, GM chipbreaker, ap=1mm) fz=0.2 mm/t(Reference value for carbon steel and GM chipbreaker)× 1.5(Conversion factor for ROMU12 type, ap=1mm)= fz=0.3 mm/t(Recommended feed rate) Recommended cutting conditions for pecking/ramping/helical milling Tool spec. Max. ap Pecking Ramping (Slant milling) Helical milling Insert Tool dia. ap Min. Cutting lengthMax. cutting depthPdXfor flat bottomMax. rampingangle RMPXtan RMPXCutting length Lat max. ramping angleMin. cutting dia.øDh1surfaceMin. cutting dia.for flat bottom facingøDh2Max. cutting dia.øDh3 16 0.7 9 8° 0.141 28 20 24 30 RD**08 type 20 425 1.4 13 9° 0.158 25185°0.08745 2636 3242 3848 20 0.6 11 5° 0.087 57 26 30 38 25 16 10° 0.176 28 33 40 48 RP**10 type 3240 5 1.9 23 6° 0.105 47314°0.07071 4763 5470 6278 50 41 3° 0.052 95 83 90 98 63 54 2° 0.035 143 109 116 124 32 21 9° 0.158 37 43 52 62 40 29 5° 0.087 68 59 68 78 RP**12 type 5063 6 2.480 39 4° 0.070 8552692°0.035171 79105139 88114148 98124158 100 89 1° 0.017 343 179 188 198 40 25 11° 0.194 41 51 64 78 50 35 7° 0.123 65 71 84 98 RP**16 type 6380 8 3.4 48 4° 0.070 114653°0.052152 97131 110144 124158 100 85 2° 0.035 229 171 184 198 125 110 1° 0.017 458 221 234 248 * Above is the value considering the clearance 1mm between the tool body and the workpiece. Unit: mm M207 Milling