Основной каталог Kyocera 2021 - 2022 - страница 869

Навигация

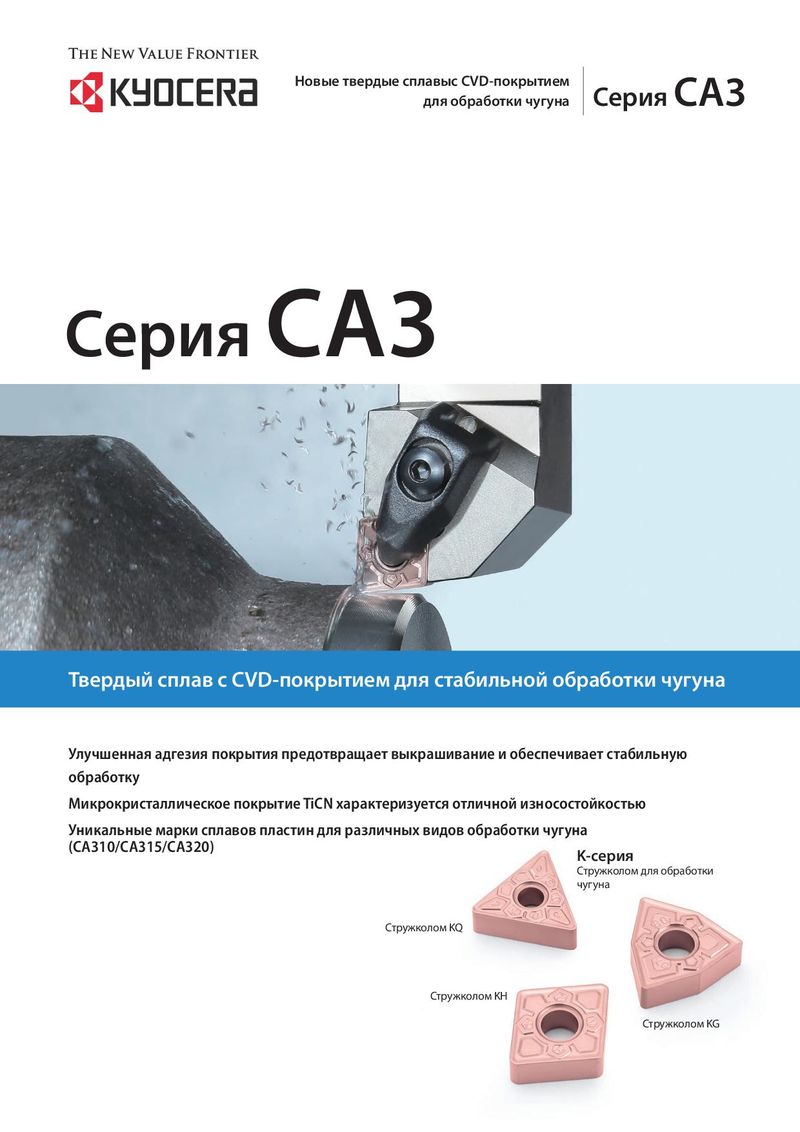

Каталог Kyocera пластины с CVD покрытием для обработки чугуна

Каталог Kyocera пластины с CVD покрытием для обработки чугуна Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA Каталог Kyocera фрезы MRX с позитивными круглыми пластинами

Каталог Kyocera фрезы MRX с позитивными круглыми пластинами Каталог Kyocera пластины с CVD покрытием для обработки стали

Каталог Kyocera пластины с CVD покрытием для обработки стали - Cover

- Chapter Overview

- Contents

- Introduction

- Introduction

- Negative-Chipbreaker

- Positive-Chipbreaker

- Page Guide

- Cermet / coated carbide / carbide lineup

- Negative inserts 80° Rhombic

- 55° Rhombic

- 55° Parallelogramm

- Round

- 90° Square

- 90° Square

- 60° Triangle

- 35° Rhombic

- 80° Trigon

- Small double sided tools

- 80° Rhombic

- 55° Rhombic

- 55° Rhombic

- 70° Rhombic

- Round

- 90° Square

- 90° Square

- 60° Triangle

- 60° Triangle

- 35° Rhombic

- 35° Rhombic

- 80° Trigon

- Bearing machining Round / Square-Type

- Inserts for back turning TKFB

- ABS / ABW

- Ceramic lineup

- Negative inserts 80° Rhombic

- 55° Rhombic

- 75° Rhombic

- Round

- 90° Square

- 60° Triangle

- 35° Rhombic

- Positive inserts Round

- Square

- Triangle

- Inserts for high hardened roll

- Grooving inserts

- CBN Lineup

- Introduction

- Solid bar EZB-NB

- GMN

- GDGS

- Grooving inserts GBA

- 80° Trigon

- 35° Rhombic

- 60° Triangle

- 55° Rhombic

- Positive inserts 80° Rhombic

- 60° Triangle / Solid

- 90° Square / Solid

- Round / Solid

- 80° Rhombic / Solid

- 80° Trigon

- 35° Rhombic

- 60° Triangle

- 90° Square

- 55° Rhombic

- Negative inserts 80° Rhombic

- PCD Lineup

- Introduction

- Milling inserts Available inserts

- VNBR-NB

- VNGR-NB

- Solid bar EZB-NB

- TKF

- GMGW

- GMN

- GDGS

- GV/GVF

- Grooving inserts GBA/TGF

- 80° Trigon

- 35° Rhombic

- 60° Triangle

- 90° Square

- 55° Rhombic

- Positive inserts 80° Rhombic

- 80° Trigon

- 35° Rhombic

- 60° Triangle

- 55° Rhombic

- Negative inserts 80° Rhombic

- Introduction

- Toolholders for general purpose

- CN insert DCLN/DCLN-JCT/PCLN

- DN insert DDJN/DDJN-JCT/DDHN

- PDJN/PDHN

- SN insert DSBN/PSBN/PSKN

- PSSN/PSDN

- TN insert DTGN/PTGN/PTFN

- WTJN/WTKN/WTEN

- VN insert DVLN/DVPN/DVVN

- MVLN/MVVN

- PVLN/PVPN/PVVN

- RC insert PRGC/PRXC

- RN insert PRGN

- WN Insert DWLN/DWLN-JCT/PWLN/WWLN

- Toolholders for ceramic inserts

- Selection guide for ceramic inserts

- RN insert CRSN/CRDN

- SN insert CSRN/CS-N/CSKN/CSYN/CSSN/CSDN

- EN insert CELN

- DN insert CDJN

- CN insert CCLN

- TN insert CTJN/CTUN

- Toolholders for CBN inserts

- CNMN insert CCRN-A/CCLN-A

- RNMN insert CRSN-A/CRDN-A

- SNMN insert CSRN-A/CSKN-A/CSSN-A/CSDN-A

- TNMN insert CTJN-A/CTUN-A

- Toolholders for bearing machining

- RCMT insert PRGC-BE

- SNMF insert CBSN

- Recommended cutting conditions

- Introduction

- Toolholders for back turning

- TKFB insert TKFB

- KTKF / KTKF Goose-neck holder

- ABS15 insert AABS-40F/SABS-40F

- ABW15 insert AABW-40F/SABW-40F

- ABW23 insert AABW-50F/SABW-50F

- Goose-neck toolholders

- DC insert SDJC

- VP insert SVLP

- External toolholders

- CC insert ACLC-FF

- SCLC

- SCLC-FF/SCLC-FFJCT

- DC insert ADJC-FF

- SDJC-FF

- SDJC-FFJCT

- SDJC

- SDLC-FF

- SDXC

- SDNC-F

- SDNC

- DP insert SDLP-FF

- TC/TP insert STGC

- STGP

- VB/VC insert AVJB-FF/SVJB-FF/SVJB-FFJCT/SVJB/SVPB/SVVB

- SVJC-FF/SVLC-FF

- SVPC-FF/SVVC

- VP insert SVJP-FF/SVJP-FFJCT/SVLP-FF/SVPP-FF

- External sleeve holders

- CC insert S...SCLC

- DC insert S...SDUC/S...SDLC

- VB/VC insert S...SVUB/S...SVUC

- Toolholders for small double sided tooling

- CN insert SCLN-FF (without offset)

- DN insert SDLN-FF (without offset)

- TN insert STLN-FF (without offset)

- Toolholders for double sided tooling for automatic lathes

- CN insert PCLN-FF (without offset)

- TN insert PTLN-FF (without offset)

- Recommended cutting conditions

- Introduction

- Solid tip bars for micro boring

- System Tip-Bars VNB type

- VNBX-S

- TWB

- STW/S-STW

- TWBT

- Dynamic-Bars

- CC insert A/S-SCLC-AE

- CP insert A-SCLP-AE

- DC insert A-SDUC-AE

- JC insert C-SJLC

- TC insert A-STLC-AE

- TB/TP insert S-STLB-AE

- VB/VC/VP insert A-SVJP-AE/A-SVJC-AE/A-SVJB-AE

- WB/WP insert S-SWUB-AE/A-SWUP-AE

- Borings bars (screw clamp / top clamp)

- SP insert S-SSKP/S-CSKP

- TP insert S-CTUP

- Bearing machining

- RPMT insert SRCP-B

- SNMF insert CBSN-B

- AD Bars

- CN insert HA-PCLN

- DN insert HA-PDUN

- TN insert HA-PTFN

- CC insert HA-SCLC

- DC insert HA-SDUC

- Boring adapter for AD Bars AD type with dampener system

- Boring bars for negative type inserts

- CN insert A-DCLN

- DN insert S-PDUN/A-PDUN (11)

- SN insert A-DSKN

- TN insert A-DTFN

- WN insert S-PWLN/A-PWLN

- Boring bars for ceramic inserts

- Boring bars for CBN inserts

- Technical information

- Applicable sleeves

- Introduction

- External grooving

- GBA type GBA

- KGB/KGBS

- GBF-KGBF-JCT

- TGF type TGF

- S-KGBF

- KTGF-F/KTGF/S-KTGF

- KGD

- KGD-JCT (Integral type)

- KGD (Integral type for automatic lathes)

- KGD (Integral type)

- KGDF S separate type

- GMGW type GMGW

- GH/GHU/GA type GH/GHU/GA

- GM/GMN/GMM/GMG/GMGA/FGG type GM/GMN/GMM/GMG/GMGA/FGG

- Internal grooving

- KGIA

- GIA type GIA

- GMM/GMG/GMGA type GMM/GMG/GMGA

- GH/GHU type GH/GHU

- GBA type KIGBA

- GDM type GDM

- GV type GV

- SIGE-WH-90 carbide shank bar (for automatic lathe; with coolant hole)

- SIGE-WH carbide shank bar (with coolant hole)

- SIGE-EH Excellent Bar (with coolant hole)

- GE/GER type GE/GER

- GC type GC

- VNG type VNG

- GMM

- Face grooving

- KGDF-Z (Integral type)

- GDFM/GDFMS type GDFM/GDMFS

- TWFG/TWFGT small diameter face grooving (Twin-Bars) TWFG

- VNFG type VNFG

- KGDF 0° separate type

- KGDF 90 separate type

- FTK type FTK

- GMM/GMG/GMGA type GMM/GMG/GMGA

- FMM/FMN type FMM/FMN

- GIFV (A/B/C)

- GFV\AA

- GVF type GVF

- Grooving

- Introduction

- Small diameter cut-off

- TKF type TKF

- KTKF

- KTKF-JCT

- KTKFS

- TKFS type TKFS

- KTKF-S

- KGD type

- GDM/GDMS/GDG type GDM/GDMS/GDG

- KGD (Integral type for automatic lathe)

- KGDS (for sub spindle tooling)

- KGD-JCT (Integral type)

- KGD (Integral type)

- KGD-JCT (Integral type for automatic lathe)

- KGD-JCT

- KGDS separate type

- KGM type

- GMM/GMN/GMR/GML type GMM/GMN/GMR/GMLw

- KGM/KGM-T/KGMM/KGMS

- 1-edge cut-off inserts

- TKN/TK type TKN/TK

- KTKB-SS/KTKB-S

- Toolblocks

- KTKH-S (Integral type)

- Introduction

- Threading inserts

- Metric External threading / 60° full profile

- Internal threading / 60° full profile

- Unified External threading / 60° full profile

- Internal threading / 60° full profile

- Parallel pipe, Whitworth External threading

- Internal threading

- Tapered pipe External threading / 55° full profile

- Internal threading / 55° full profile

- American national tapered pipe External threading

- Internal threading

- 60° type (Partial profile/M, UN) External threading

- Internal threading

- 55° type (Partial profile/G, R, Rc, W) External threading

- Internal threading

- 30° type (Trapezoidal) External threading

- Internal threading

- Threading toolholders

- External toolholders KTN/KTNS/KTN-JCT

- S-KTN

- Internal toolholders SIN/CIN

- Multipurpose threading tools

- TKFT for small parts machining TKFT

- KTKF

- TTX for small parts machining TTX

- KTTX/S-KTTX

- TT for external and internal threading TT

- KTT (external)

- KITG (internal)

- System Bar for micro internal threading VNT

- TPGB for internal threading TPGB

- S-STWP/S-STWP-E

- Recommended cutting conditions

- Depth of cut and number of passes

- Applicable toolholders and inserts

- Threading methods

- Threading methods and basic profiles

- Thread types

- Introduction

- MagicDrill DRA

- SF-DRA 12 DC

- SF-DRA 8 DC

- SF-DRA 5 DC

- SF-DRA 3 DC

- Flanged shank SF SF-DRA 1.5 DC

- Chamfering attachment for SS-DRA CH\-DRA

- SS-DRA 8 DC

- SS-DRA 5 DC

- SS-DRA 3 DC

- Straight shank SS SS-DRA 1.5 DC

- Recommended cutting conditions

- MagicDrill DRC

- Straight shank SS SS-DRC 3 DC

- SS-DRC 5 DC

- SS-DRC 8 DC

- Chamfering attachment for SS-DRC CH\-DRC

- Flanged shank SF SF-DRC 3 DC

- SF-DRC 5 DC

- SF-DRC 8 DC

- Recommended cutting conditions

- MagicDrill DRV

- Chamfering attachment for DRV CH\-DRV

- DRV 6 DC

- DRV 5 DC

- DRV 4 DC

- DRV 3 DC

- Toolholder DRV DRV 2 DC

- Recommended cutting conditions

- Adjustable sleeve (DRV/DRZ/DRX)

- MagicDrill DRZ

- Toolholder DRZ DRZ 2 DC

- DRZ 3 DC

- DRZ-CR

- Recommended cutting conditions

- MagicDrill DRS

- MagicDrill DRX

- Trouble shooting (DRV / DRX / DRZ / DRX)

- Lathe installation DRX/DRZ

- MagicDrill DRW

- Introduction

- Introduction

- ISO identification

- MFPN Series MFPN66

- MFK / MFK-SF

- MOF45 OFMT

- Lead angle 15°

- MSRS15 SPMT

- Lead angle 0°/ 2°

- MEW LOMU/LOGT

- MEC/MECX BDGT/BDMT

- MEWH LOMU/LOGT

- MEV TOMT

- MECH/MECHT BDMT

- MECH/MECHT MECHT

- MFWN WNEU/WNMU/WNGT

- MFSN88 SNMU

- MFLN90 LOGU

- MSRS90 SPMT

- MSR / MSR-BT50 APMT

- DMC/DMC-SX/DMC-H NDCT/NDCW/NDMM

- MFAH ENET

- MEAS KCGT

- High feed cutter

- MFH Series SOMT/LOGU/LPGT

- MFH Series MFH Mini

- MFH Series MFH Micro

- Multi-Function end mill

- Applicable inserts GOMT/JOMT

- Slott mill

- Ball-nose / radius type cutters

- MRF/MRFW RDFG

- MRW ROMU

- MRX RDMT/RDGT/RPMT/RPGT

- Other applications

- MCSE (chamfering end mill)

- Square-type inserts MEF (bolt countersink end mill)

- S type inserts METS (T-Slot mill)

- MVG (ring grooving end milll for M/C)

- GVR/GVFR

- MGI (grooving end mill for M/C)

- Grooving GVR/GVFR

- Other inserts

Lead angle 0°/ 2° MFSN88 Cutting edge angle 88˚, high efficiency cutter MFSN88 Economical double-sided 8-edge insert suitable for shoulder roughing Reduces chattering with a low cutting force design Applicable to various types of machining with product lineup from ø32 1 Economical double-sided 8-edge insertsuitable for shoulder roughing Cost reduction in approximately 90˚corner cutting Shoulder roughing Cost reduction by switching from Facing without interfering with fixtures 90˚ cutter with positive inserts MFSN88 Conventional 45˚ cutter Jig M See page M100 for unmachined corner portion 2 Reduces chattering with alow cutting force design 3 Extended tool life byMEGACOAT NANO Chatter resistant medium to roughing Insert grade and chipbreaker lineup machining range for various machining application Cutting force comparison (Internal evaluation) 300 21% 261 200 206 DOWN 1st Recommendation Tough edge For stainless steel (General purpose) 100 GM chipbreaker GH chipbreaker SM chipbreaker 0 MFSN88 Competitor A Cutting force is thrust force Cutting conditions: Vc = 200 m/min, ap = 3mm, fz = 0.15mm/t Cutter dia. ø63: Workpiece material: S50C M97 Cutting force (N) Milling