Каталог Sumitomo токарные резцы (державки) для наружного точения - страница 8

Навигация

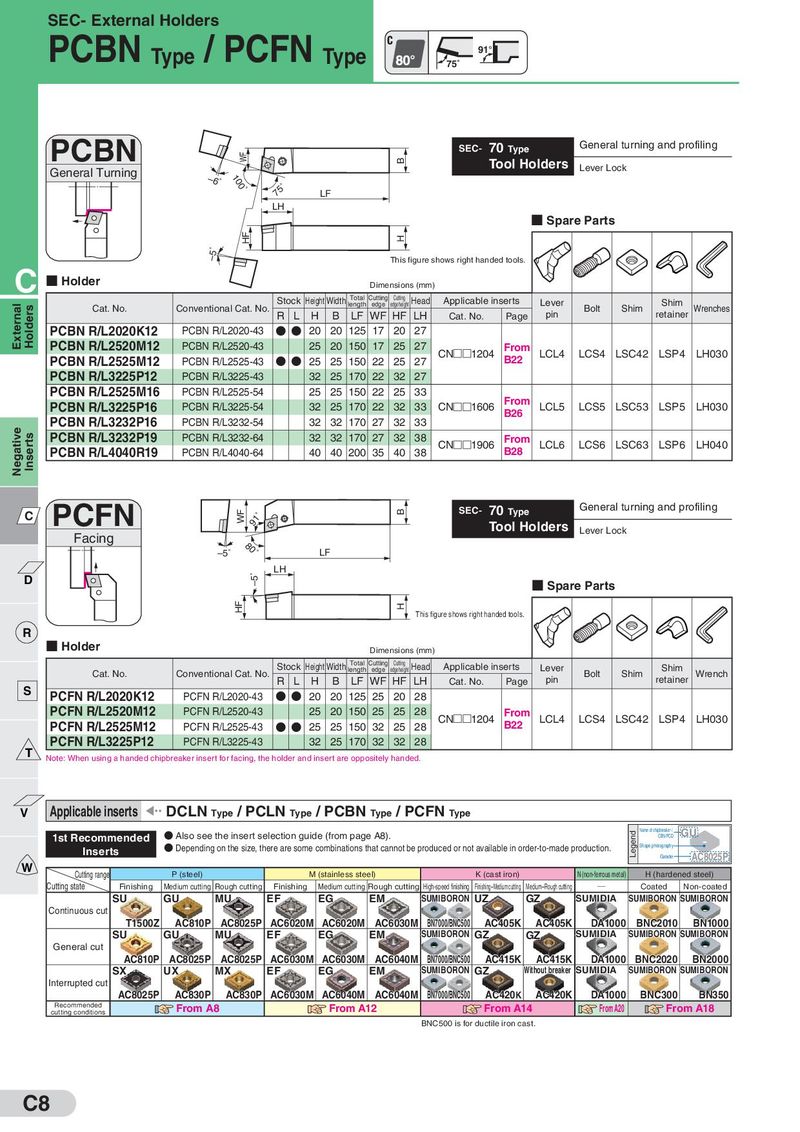

SEC- External Holders PCBN Type / PCFN Type 91° 75˚ PCBN SEC- 70 Type General turning and profiling WF B Tool Holders General Turning Lever Lock –6˚ 100˚ 75˚ LF LH ■ Spare Parts HF H –5˚ This figure shows right handed tools. C ■ Holder Dimensions (mm) Stock Height Width Total Cutting Cutting Head Applicable inserts Lever Shim External Holders Cat. No. Conventional Cat. No. length edge edge height Bolt Shim Wrenches R L H B LF WF HF LH Cat. No. Page pin retainer PCBN R/L2020K12 PCBN R/L2020-43 ●● 20 20 125 17 20 27 PCBN R/L2520M12 PCBN R/L2520-43 25 20 150 17 25 27 CN 1204 From LCL4 LCS4 LSC42 LSP4 LH030 PCBN R/L2525M12 PCBN R/L2525-43 ●● 25 25 150 22 25 27 B22 PCBN R/L3225P12 PCBN R/L3225-43 32 25 170 22 32 27 PCBN R/L2525M16 PCBN R/L2525-54 25 25 150 22 25 33 From PCBN R/L3225P16 PCBN R/L3225-54 32 25 170 22 32 33 CN 1606 B26 LCL5 LCS5 LSC53 LSP5 LH030 Negative PCBN R/L3232P16 PCBN R/L3232-54 32 32 170 27 32 33 Inserts PCBN R/L3232P19 PCBN R/L3232-64 32 32 170 27 32 38 CN 1906 From LCL6 LCS6 LSC63 LSP6 LH040 PCBN R/L4040R19 PCBN R/L4040-64 40 40 200 35 40 38 B28 C PCFN WF B SEC- 70 Type General turning and profiling 91˚ Tool Holders Facing Lever Lock –5˚ 80˚ LF –5˚ LH D ■ Spare Parts HF H This figure shows right handed tools. R ■ Holder Dimensions (mm) Stock Height Width Total Cutting Cutting Head Applicable inserts Lever Shim Cat. No. Conventional Cat. No. length edge edge height Bolt Shim Wrench R L H B LF WF HF LH Cat. No. Page pin retainer S PCFN R/L2020K12 PCFN R/L2020-43 ●● 20 20 125 25 20 28 PCFN R/L2520M12 PCFN R/L2520-43 25 20 150 25 25 28 CN 1204 From LCL4 LCS4 LSC42 LSP4 LH030 PCFN R/L2525M12 PCFN R/L2525-43 ●● 25 25 150 32 25 28 B22 PCFN R/L3225P12 PCFN R/L3225-43 32 25 170 32 32 28 T Note: When using a handed chipbreaker insert for facing, the holder and insert are oppositely handed. V Applicable inserts DCLN Type / PCLN Type / PCBN Type / PCFN Type ● Also see the insert selection guide (from page A8). Legend Name of chipbreaker / GU 1st Recommended CBN/PCD Inserts ● Depending on the size, there are some combinations that cannot be produced or not available in order-to-made production. Shape photography Grade AC8025P W Cutting range P (steel) M (stainless steel) K (cast iron) N (non-ferrous metal) H (hardened steel) Cutting state Finishing Medium cutting Rough cutting Finishing Medium cutting Rough cutting High-speed finishing Finishing–Medium cutting Medium–Rough cutting ─ Coated Non-coated SU GU MU EF EG EM SUMIBORON UZ GZ SUMIDIA SUMIBORON SUMIBORON Continuous cut T1500Z AC810P AC8025P AC6020M AC6020M AC6030M BN7000/BNC500 AC405K AC405K DA1000 BNC2010 BN1000 SU GU MU EF EG EM SUMIBORON GZ GZ SUMIDIA SUMIBORON SUMIBORON General cut AC810P AC8025P AC8025P AC6030M AC6030M AC6040M BN7000/BNC500 AC415K AC415K DA1000 BNC2020 BN2000 SX UX MX EF EG EM SUMIBORON GZ Without breaker SUMIDIA SUMIBORON SUMIBORON Interrupted cut AC8025P AC830P AC830P AC6030M AC6040M AC6040M BN7000/BNC500 AC420K AC420K DA1000 BNC300 BN350 Recommended From A8 From A12 From A14 From A20 From A18 cutting conditions BNC500 is for ductile iron cast. C8

Каталог Sumitomo модульные фрезерные системы

Каталог Sumitomo модульные фрезерные системы Техническая информация Sumitomo

Техническая информация Sumitomo Каталог Sumitomo сверла и развертки

Каталог Sumitomo сверла и развертки Каталог Sumitomo резьбонарезной инструмент

Каталог Sumitomo резьбонарезной инструмент Каталог Sumitomo твердосплавные пластины

Каталог Sumitomo твердосплавные пластины