Каталог Sumitomo токарные резцы (державки) для наружного точения - страница 4

Навигация

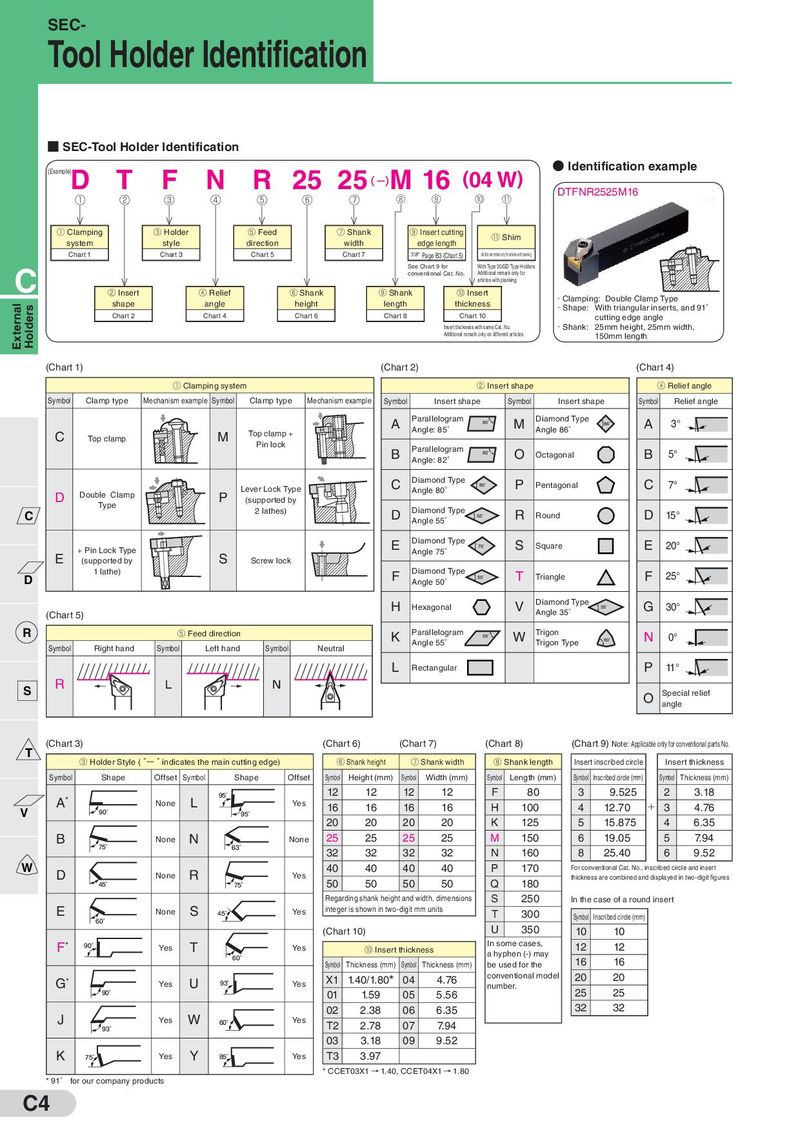

SEC- Tool Holder Identification ■ SEC-Tool Holder Identification D (Example) T F N R 25 25(−)M 16 (04 W) ● Identification example ① ② ③ ④ ⑤ ⑥ ⑦ ⑧ ⑨ ⑩ ⑪ DTFNR2525M16 ① Clamping ③ Holder ⑤ Feed ⑦ Shank ⑨ Insert cutting ⑪ Shim system style direction width edge length Chart 1 Chart 3 Chart 5 Chart 7 ☞ Page B3 (Chart 5) Additional remark only for articles with planking C See Chart 9 for With Type 30/GD Type Holders conventional Cat. No. Additional remark only for articles with planking ② Insert ④ Relief ⑥ Shank ⑧ Shank ⑩ Insert ・Clamping: Double Clamp Type External Holders shape angle height length thickness ・Shape: With triangular inserts, and 91 Chart 2 Chart 4 Chart 6 Chart 8 Chart 10 cutting edge angle Insert thickness with same Cat. No. ・Shank: 25mm height, 25mm width, Additional remark only on different articles 150mm length (Chart 1) (Chart 2) (Chart 4) ① Clamping system ② Insert shape ④ Relief angle Symbol Clamp type Mechanism example Symbol Clamp type Mechanism example Symbol Insert shape Symbol Insert shape Symbol Relief angle A Parallelogram 85˚ M Diamond Type 86˚ A 3° C M Top clamp + Angle: 85° Angle 86° Top clamp Pin lock B Parallelogram 82˚ O Octagonal B 5° Angle: 82° C Diamond Type 80˚ P Pentagonal C 7° D Double Clamp P Lever Lock Type Angle 80° Type (supported by C 2 lathes) D Diamond Type 55˚ R Round D 15° Angle 55° E Diamond Type 75˚ S Square E 20° E + Pin Lock Type S Angle 75° (supported by Screw lock D 1 lathe) F Diamond Type 50˚ T Triangle F 25° Angle 50° H Hexagonal V Diamond Type 35˚ G 30° (Chart 5) Angle 35° R ⑤ Feed direction K Parallelogram 55˚ W Trigon N 0° Angle 55° Trigon Type 80˚ Symbol Right hand Symbol Left hand Symbol Neutral L Rectangular P 11° S R L N Special relief O angle T (Chart 3) (Chart 6) (Chart 7) (Chart 8) (Chart 9) Note: Applicable only for conventional parts No. ③ Holder Style ( ー indicates the main cutting edge) ⑥ Shank height ⑦ Shank width ⑧ Shank length Insert inscribed circle Insert thickness Symbol Shape Offset Symbol Shape Offset Symbol Height (mm) Symbol Width (mm) Symbol Length (mm) Symbol Inscribed circle (mm) Symbol Thickness (mm) A* L 95˚ 12 12 12 12 F 80 3 9.525 2 3.18 None Yes 16 16 16 16 H 100 4 12.70 + 3 4.76 V 90˚ 95˚ 20 20 20 20 K 125 5 15.875 4 6.35 B None N None 25 25 25 25 M 150 6 19.05 5 7.94 75˚ 63˚ 32 32 32 32 N 160 8 25.40 6 9.52 W D R 40 40 40 40 P 170 For conventional Cat. No., inscribed circle and insert None Yes 50 50 50 50 Q 180 thickness are combined and displayed in two-digit figures 45˚ 75˚ Regarding shank height and width, dimensions S 250 In the case of a round insert E None S 45˚ Yes integer is shown in two-digit mm units T 300 60˚ Symbol Inscribed circle (mm) (Chart 10) U 350 10 10 F* 90˚ Yes T Yes ⑩ Insert thickness In some cases, 12 12 60˚ a hyphen (-) may 16 16 Symbol Thickness (mm) Symbol Thickness (mm) be used for the G* U X1 1.40/1.80* 04 4.76 conventional model 20 20 Yes 93˚ Yes number. 90˚ 01 1.59 05 5.56 25 25 02 2.38 06 6.35 32 32 J Yes W 60˚ Yes T2 2.78 07 7.94 93˚ 03 3.18 09 9.52 K 75˚ Yes Y 85˚ Yes T3 3.97 * CCET03X1 → 1.40, CCET04X1 → 1.80 * 91° for our company products C4

Каталог Sumitomo модульные фрезерные системы

Каталог Sumitomo модульные фрезерные системы Техническая информация Sumitomo

Техническая информация Sumitomo Каталог Sumitomo сверла и развертки

Каталог Sumitomo сверла и развертки Каталог Sumitomo резьбонарезной инструмент

Каталог Sumitomo резьбонарезной инструмент Каталог Sumitomo твердосплавные пластины

Каталог Sumitomo твердосплавные пластины