Каталог Sumitomo токарные резцы (державки) для наружного точения - страница 12

Навигация

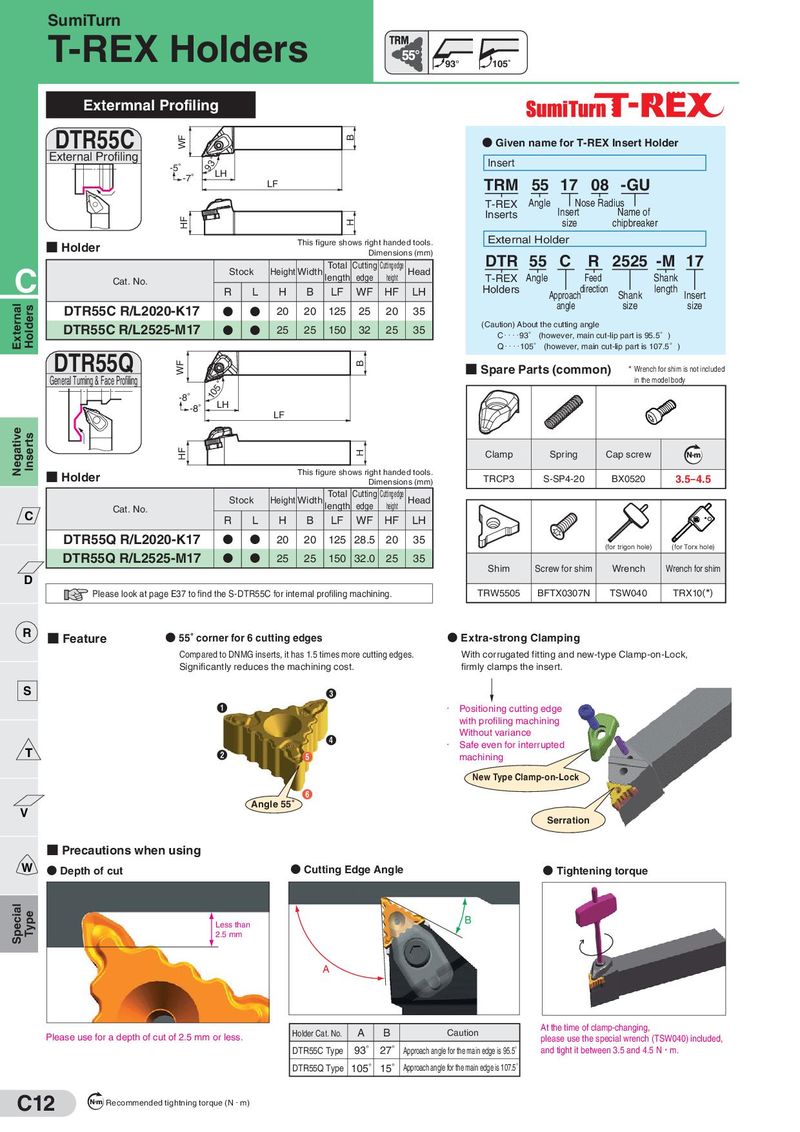

SumiTurn T-REX Holders 93° 105˚ Extermnal Profiling DTR55C WF B ● Given name for T-REX Insert Holder External Profiling 93゚ Insert -5° LH -7° LF TRM 55 17 08 -GU T-REX Angle Nose Radius Insert Name of HF Inserts H size chipbreaker ■ Holder This figure shows right handed tools. External Holder Dimensions (mm) DTR 55 C R 2525 -M 17 C Stock Height Width Total Cutting Cutting edge Head Cat. No. length edge height T-REX Angle Feed Shank R L H B LF WF HF LH Holders Approachdirection Shank length Insert External Holders DTR55C R/L2020-K17 ● ● 20 20 125 25 20 35 angle size size DTR55C R/L2525-M17 ● ● 25 25 150 32 25 35 (Caution) About the cutting angle C‥‥93° (however, main cut-lip part is 95.5°) Q‥‥105° (however, main cut-lip part is 107.5°) DTR55Q WF B ■ Spare Parts (common) * Wrench for shim is not included General Turning & Face Profiling 105゚ in the model body -8° LH -8° LF Negative Inserts HF H Clamp Spring Cap screw Nm ■ Holder This figure shows right handed tools. TRCP3 S-SP4-20 BX0520 3.5‒4.5 Dimensions (mm) Stock Height Width Total Cutting Cutting edge Head C Cat. No. length edge height R L H B LF WF HF LH DTR55Q R/L2020-K17 ● ● 20 20 125 28.5 20 35 (for trigon hole) (for Torx hole) DTR55Q R/L2525-M17 ● ● 25 25 150 32.0 25 35 Shim Screw for shim Wrench Wrench for shim D Please look at page E37 to find the S-DTR55C for internal profiling machining. TRW5505 BFTX0307N TSW040 TRX10(*) R ■ Feature ● 55 corner for 6 cutting edges ● Extra-strong Clamping Compared to DNMG inserts, it has 1.5 times more cutting edges. With corrugated fitting and new-type Clamp-on-Lock, Significantly reduces the machining cost. firmly clamps the insert. S ❸ ↓ ❶ ・ Positioning cutting edge with profiling machining ❹ Without variance T ・ Safe even for interrupted ❷ ●❺ machining New Type Clamp-on-Lock ❻ V Angle 55 Serration ■ Precautions when using W ● Depth of cut ● Cutting Edge Angle ● Tightening torque Special Type Less than B 2.5 mm A Holder Cat. No. A B Caution At the time of clamp-changing, Please use for a depth of cut of 2.5 mm or less. please use the special wrench (TSW040) included, DTR55C Type 93° 27° Approach angle for the main edge is 95.5° and tight it between 3.5 and 4.5 N・m. DTR55Q Type 105°15° Approach angle for the main edge is 107.5° C12 N m Recommended tightning torque (N・m)

Каталог Sumitomo модульные фрезерные системы

Каталог Sumitomo модульные фрезерные системы Техническая информация Sumitomo

Техническая информация Sumitomo Каталог Sumitomo сверла и развертки

Каталог Sumitomo сверла и развертки Каталог Sumitomo резьбонарезной инструмент

Каталог Sumitomo резьбонарезной инструмент Каталог Sumitomo твердосплавные пластины

Каталог Sumitomo твердосплавные пластины