Каталог Sumitomo токарные резцы (державки) для наружного точения - страница 23

Навигация

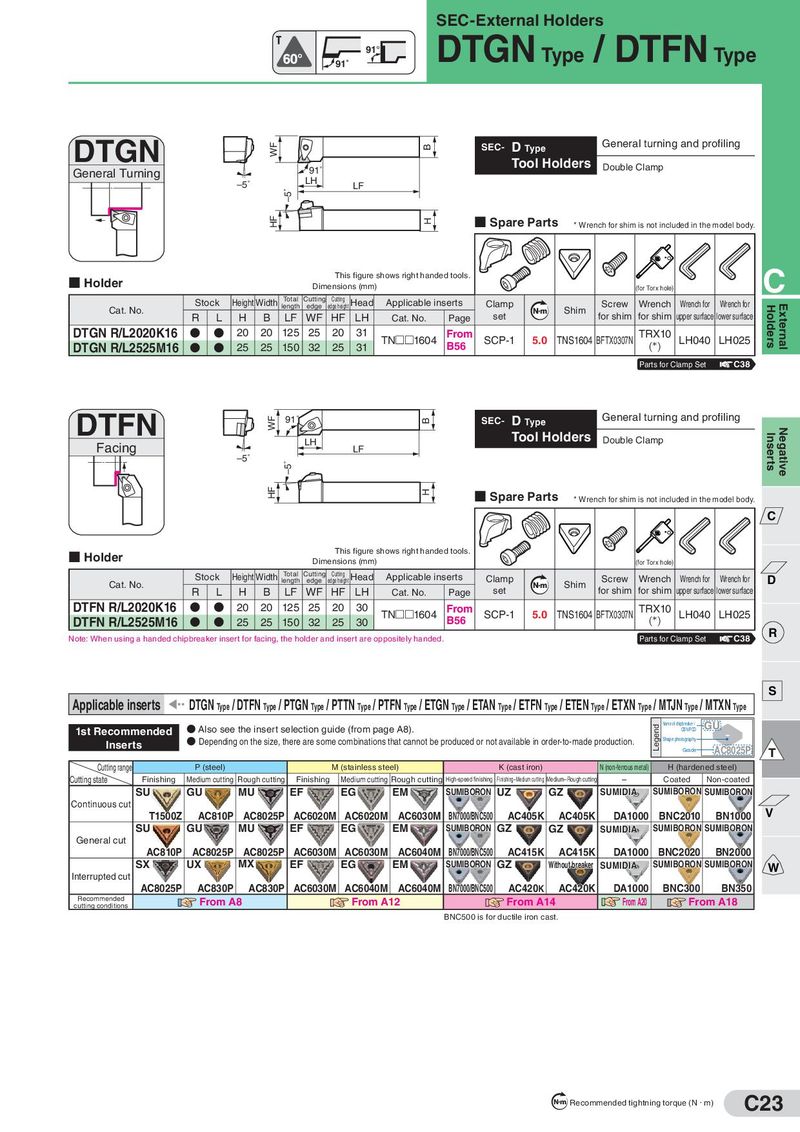

SEC-External Holders 91° DTGN Type / DTFN Type 91˚ DTGN WF B SEC- D Type General turning and profiling General Turning 91˚ Tool Holders Double Clamp –5˚ LH LF –5˚ HF H ■ Spare Parts * Wrench for shim is not included in the model body. ■ Holder This figure shows right handed tools. C Dimensions (mm) (for Torx hole) Stock Height Width Total Cutting Cutting Head Applicable inserts Clamp Screw Wrench Wrench for Wrench for Cat. No. length edge edge height Nm Shim Holders External R L H B LF WF HF LH Cat. No. Page set for shim for shim upper surface lower surface DTGN R/L2020K16 ● ● 20 20 125 25 20 31 TN 1604 From SCP-1 5.0 TNS1604 BFTX0307N TRX10 LH040 LH025 DTGN R/L2525M16 ● ● 25 25 150 32 25 31 B56 (*) Parts for Clamp Set C38 DTFN WF 91˚ B SEC- D Type General turning and profiling Facing LH Tool Holders Double Clamp Inserts Negative LF –5˚ –5˚ HF H ■ Spare Parts * Wrench for shim is not included in the model body. C ■ Holder This figure shows right handed tools. Dimensions (mm) (for Torx hole) Stock Height Width Total Cutting Cutting Head Applicable inserts Clamp Screw Wrench Wrench for Wrench for D Cat. No. length edge edge height Nm Shim R L H B LF WF HF LH Cat. No. Page set for shim for shim upper surface lower surface DTFN R/L2020K16 ● ● 20 20 125 25 20 30 TN 1604 From SCP-1 5.0 TNS1604 BFTX0307N TRX10 LH040 LH025 DTFN R/L2525M16 ● ● 25 25 150 32 25 30 B56 (*) Note: When using a handed chipbreaker insert for facing, the holder and insert are oppositely handed. Parts for Clamp Set C38 R S Applicable inserts DTGN Type / DTFN Type / PTGN Type / PTTN Type / PTFN Type / ETGN Type / ETAN Type / ETFN Type / ETEN Type / ETXN Type / MTJN Type / MTXN Type ● Also see the insert selection guide (from page A8). Legend Name of chipbreaker / GU 1st Recommended CBN/PCD Inserts ● Depending on the size, there are some combinations that cannot be produced or not available in order-to-made production. Shape photography Grade AC8025P T Cutting range P (steel) M (stainless steel) K (cast iron) N (non-ferrous metal) H (hardened steel) Cutting state Finishing Medium cutting Rough cutting Finishing Medium cutting Rough cutting High-speed finishing Finishing–Medium cutting Medium–Rough cutting – Coated Non-coated SU GU MU EF EG EM SUMIBORON UZ GZ SUMIDIA SUMIBORON SUMIBORON Continuous cut V T1500Z AC810P AC8025P AC6020M AC6020M AC6030M BN7000/BNC500 AC405K AC405K DA1000 BNC2010 BN1000 SU GU MU EF EG EM SUMIBORON GZ GZ SUMIDIA SUMIBORON SUMIBORON General cut AC810P AC8025P AC8025P AC6030M AC6030M AC6040M BN7000/BNC500 AC415K AC415K DA1000 BNC2020 BN2000 SX UX MX EF EG EM SUMIBORON GZ Without breaker SUMIDIA SUMIBORON SUMIBORON W Interrupted cut AC8025P AC830P AC830P AC6030M AC6040M AC6040M BN7000/BNC500 AC420K AC420K DA1000 BNC300 BN350 Recommended From A8 From A12 From A14 From A20 From A18 cutting conditions BNC500 is for ductile iron cast. N m Recommended tightning torque (N・m) C23

Каталог Sumitomo модульные фрезерные системы

Каталог Sumitomo модульные фрезерные системы Техническая информация Sumitomo

Техническая информация Sumitomo Каталог Sumitomo сверла и развертки

Каталог Sumitomo сверла и развертки Каталог Sumitomo резьбонарезной инструмент

Каталог Sumitomo резьбонарезной инструмент Каталог Sumitomo твердосплавные пластины

Каталог Sumitomo твердосплавные пластины