Каталог Sumitomo специальные торцевые фрезы - страница 5

Навигация

- H001

- H002

- H003

- H004

- H005

- H006

- H007

- H008

- H009

- H010

- H011

- H012

- H013

- H014

- H015

- H016

- H017

- H018

- H019

- H020

- H021

- H022

- H023

- H024

- H025

- H026

- H027

- H028

- H029

- H030

- H031

- H032

- H033

- H034

- H035

- H036

- H037

- H038

- H039

- H040

- H041

- H042

- H043

- H044

- H045

- H046

- H047

- H048

- H049

- H050

- H051

- H052

- H053

- H054

- H055

- H056

- H057

- H058

- H059

- H060

- H061

- H062

- H063

- H064

- H065

- H066

- H067

- H068

- H069

- H070

- H071

- H072

- H073

- H074

- H075

- H076

- H077

- H078

- H079

- H080

- H081

- H082

- H083

- H084

- H085

- H086

- H087

- H088

- H089

- H090

- H091

- H092

- H093

- H094

- H095

- H096

- H097

- H098

- H099

- H100

- H101

- H102

- H103

- H104

- H105

- H106

- H107

- H108

- H109

- H110

- H111

- H112

- H113

- H114

- H115

- H116

- H117

- H118

- H119

- H120

- H121

- H122

- H123

- H124

- H125

- H126

- H127

- H128

- H129

- H130

- H131

- H132

- H133

- H134

- H135

- H136

- H137

- H138

- H139

- H140

- H141

- H142

- H143

- H144

- H145

- H146

- H147

- H148

- H149

- H150

- H151

- H152

- H153

- H154

- H155

- H156

- H157

- H158

- H159

- H160

- H161

- H162

- H163

- H164

- H165

- H166

- H167

- H168

- H169

- H170

- H171

- H172

- H173

- H174

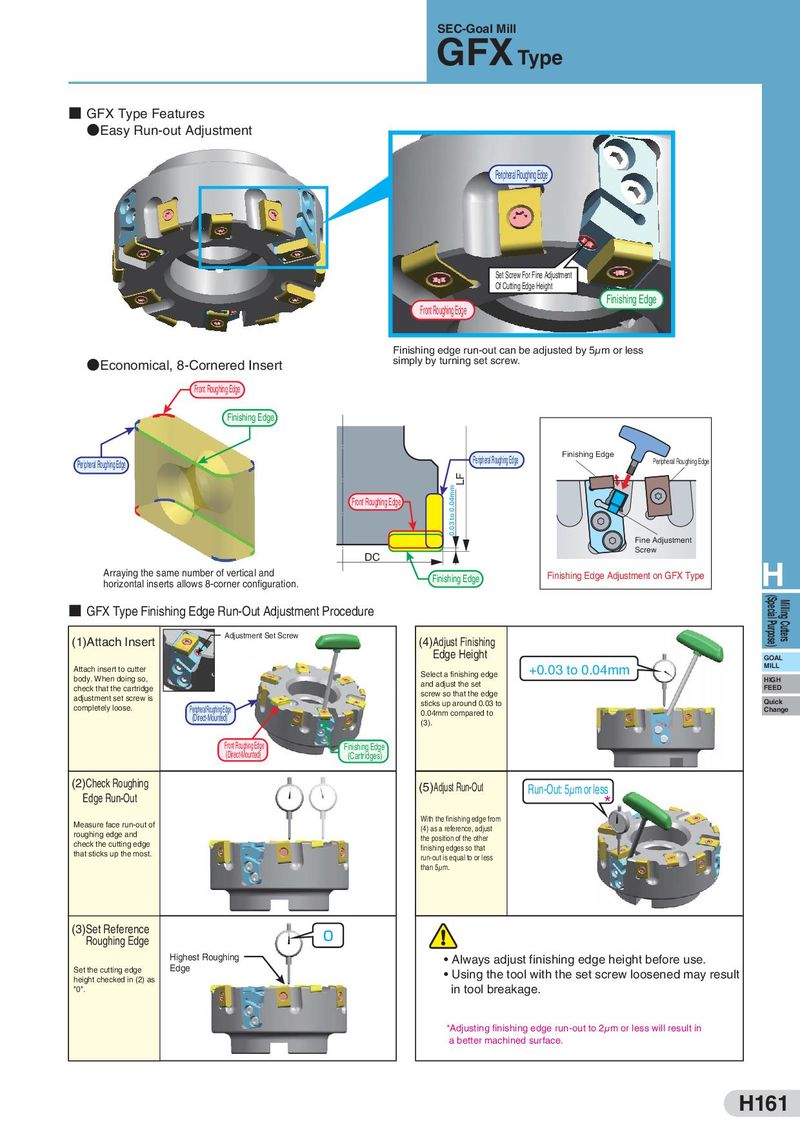

SEC-Goal Mill GFX Type ■ GFX Type Features ●Easy Run-out Adjustment Peripheral Roughing Edge Set Screw For Fine Adjustment Of Cutting Edge Height Front Roughing Edge Finishing Edge Finishing edge run-out can be adjusted by 5μm or less ●Economical, 8-Cornered Insert simply by turning set screw. Front Roughing Edge Finishing Edge Peripheral Roughing Edge Finishing Edge Peripheral Roughing Edge Peripheral Roughing Edge LF Front Roughing Edge 0.03 to 0.04mm Fine Adjustment DC Screw Arraying the same number of vertical and Finishing Edge Finishing Edge Adjustment on GFX Type H horizontal inserts allows 8-corner configuration. ■ GFX Type Finishing Edge Run-Out Adjustment Procedure (Special Purpose) Milling Cutters (1)Attach Insert Adjustment Set Screw (4)Adjust Finishing Edge Height GOAL Attach insert to cutter +0.03 to 0.04mm MILL body. When doing so, Select a finishing edge HIGH check that the cartridge and adjust the set FEED adjustment set screw is screw so that the edge completely loose. sticks up around 0.03 to Quick Peripheral Roughing Edge 0.04mm compared to Change (Direct-Mounted) (3). Front Roughing Edge Finishing Edge (Direct-Mounted) (Cartridges) (2)Check Roughing (5)Adjust Run-Out Run-Out: 5μm or less Edge Run-Out * Measure face run-out of With the finishing edge from roughing edge and (4) as a reference, adjust check the cutting edge the position of the other that sticks up the most. finishing edges so that run-out is equal to or less than 5μm. (3)Set Reference 0 Roughing Edge Highest Roughing • Always adjust finishing edge height before use. Set the cutting edge Edge • Using the tool with the set screw loosened may result height checked in (2) as in tool breakage. "0". *Adjusting finishing edge run-out to 2μm or less will result in a better machined surface. H161

Техническая информация Sumitomo

Техническая информация Sumitomo Каталог Sumitomo резьбонарезной инструмент

Каталог Sumitomo резьбонарезной инструмент Каталог Sumitomo микроинструмент

Каталог Sumitomo микроинструмент Каталог Sumitomo твердосплавные заготовки

Каталог Sumitomo твердосплавные заготовки Каталог Sumitomo инструмент для отрезки

Каталог Sumitomo инструмент для отрезки Каталог Sumitomo запасные части

Каталог Sumitomo запасные части