Каталог Sumitomo специальные торцевые фрезы - страница 11

Навигация

- H001

- H002

- H003

- H004

- H005

- H006

- H007

- H008

- H009

- H010

- H011

- H012

- H013

- H014

- H015

- H016

- H017

- H018

- H019

- H020

- H021

- H022

- H023

- H024

- H025

- H026

- H027

- H028

- H029

- H030

- H031

- H032

- H033

- H034

- H035

- H036

- H037

- H038

- H039

- H040

- H041

- H042

- H043

- H044

- H045

- H046

- H047

- H048

- H049

- H050

- H051

- H052

- H053

- H054

- H055

- H056

- H057

- H058

- H059

- H060

- H061

- H062

- H063

- H064

- H065

- H066

- H067

- H068

- H069

- H070

- H071

- H072

- H073

- H074

- H075

- H076

- H077

- H078

- H079

- H080

- H081

- H082

- H083

- H084

- H085

- H086

- H087

- H088

- H089

- H090

- H091

- H092

- H093

- H094

- H095

- H096

- H097

- H098

- H099

- H100

- H101

- H102

- H103

- H104

- H105

- H106

- H107

- H108

- H109

- H110

- H111

- H112

- H113

- H114

- H115

- H116

- H117

- H118

- H119

- H120

- H121

- H122

- H123

- H124

- H125

- H126

- H127

- H128

- H129

- H130

- H131

- H132

- H133

- H134

- H135

- H136

- H137

- H138

- H139

- H140

- H141

- H142

- H143

- H144

- H145

- H146

- H147

- H148

- H149

- H150

- H151

- H152

- H153

- H154

- H155

- H156

- H157

- H158

- H159

- H160

- H161

- H162

- H163

- H164

- H165

- H166

- H167

- H168

- H169

- H170

- H171

- H172

- H173

- H174

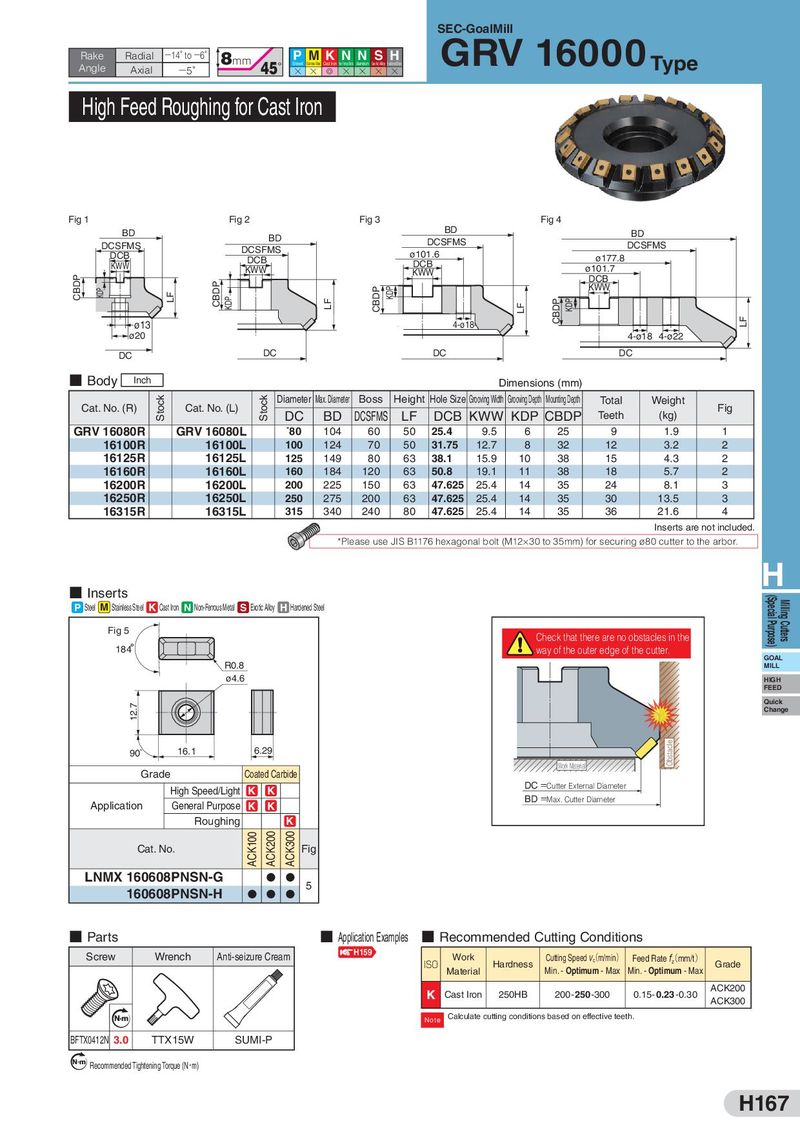

SEC-GoalMill Rake Radial −14°to −6° 8mm P MKN N SH GRV 16000 Type Angle Axial 45° Steel Stainless Steel Cast Iron Non-Ferrous Metal Aluminum Exotic Alloy Hardened Steel −5° H H G H H H H High Feed Roughing for Cast Iron Fig 1 Fig 2 Fig 3 Fig 4 BD BD BD BD DCSFMS DCSFMS DCSFMS DCSFMS DCB DCB ø101.6 ø177.8 KWW KWW DCB ø101.7 CBDP KWW DCB KDP LF CBDP CBDP KDP KWW KDP LF LF CBDP KDP ø13 4-ø18 LF ø20 4-ø18 4-ø22 DC DC DC DC ■ Body Inch Dimensions (mm) Cat. No. (R) Stock Cat. No. (L) Stock Diameter Max. Diameter Boss Height Hole Size Grooving Width Grooving Depth Mounting Depth Total Weight Fig DC BD DCSFMS LF DCB KWW KDP CBDP Teeth (kg) GRV 16080R GRV 16080L *80 104 60 50 25.4 9.5 6 25 9 1.9 1 16100R 16100L 100 124 70 50 31.75 12.7 8 32 12 3.2 2 16125R 16125L 125 149 80 63 38.1 15.9 10 38 15 4.3 2 16160R 16160L 160 184 120 63 50.8 19.1 11 38 18 5.7 2 16200R 16200L 200 225 150 63 47.625 25.4 14 35 24 8.1 3 16250R 16250L 250 275 200 63 47.625 25.4 14 35 30 13.5 3 16315R 16315L 315 340 240 80 47.625 25.4 14 35 36 21.6 4 Inserts are not included. *Please use JIS B1176 hexagonal bolt (M12×30 to 35mm) for securing ø80 cutter to the arbor. ■ Inserts H P Steel M Stainless Steel K Cast Iron N Non-Ferrous Metal S Exotic Alloy H Hardened Steel (Special Purpose) Milling Cutters Fig 5 Check that there are no obstacles in the 184 way of the outer edge of the cutter. GOAL R0.8 MILL ø4.6 HIGH FEED 12.7 Quick Change 90˚ 16.1 6.29 Obstacle Work Material Grade Coated Carbide High Speed/Light K K DC =Cutter External Diameter Application General Purpose K K BD =Max. Cutter Diameter Roughing K Cat. No. ACK100 ACK200 ACK300 Fig LNMX 160608PNSN-G D D 5 160608PNSN-H D D D ■ Parts ■ Application Examples ■ Recommended Cutting Conditions Screw Wrench Anti-seizure Cream H159 Work Cutting Speed (c m/min) Feed Rate (z mm/t) ISO Material Hardness Min. - Optimum - Max Min. - Optimum - Max Grade K Cast Iron 250HB 200- 250 -300 0.15- 0.23 -0.30 ACK200 ACK300 Nm Note Calculate cutting conditions based on effective teeth. BFTX0412N 3.0 TTX15W SUMI-P N m Recommended Tightening Torque (N・m) H167

Техническая информация Sumitomo

Техническая информация Sumitomo Каталог Sumitomo резьбонарезной инструмент

Каталог Sumitomo резьбонарезной инструмент Каталог Sumitomo микроинструмент

Каталог Sumitomo микроинструмент Каталог Sumitomo твердосплавные заготовки

Каталог Sumitomo твердосплавные заготовки Каталог Sumitomo инструмент для отрезки

Каталог Sumitomo инструмент для отрезки Каталог Sumitomo запасные части

Каталог Sumitomo запасные части