Каталог Sumitomo специальные торцевые фрезы - страница 3

Навигация

- H001

- H002

- H003

- H004

- H005

- H006

- H007

- H008

- H009

- H010

- H011

- H012

- H013

- H014

- H015

- H016

- H017

- H018

- H019

- H020

- H021

- H022

- H023

- H024

- H025

- H026

- H027

- H028

- H029

- H030

- H031

- H032

- H033

- H034

- H035

- H036

- H037

- H038

- H039

- H040

- H041

- H042

- H043

- H044

- H045

- H046

- H047

- H048

- H049

- H050

- H051

- H052

- H053

- H054

- H055

- H056

- H057

- H058

- H059

- H060

- H061

- H062

- H063

- H064

- H065

- H066

- H067

- H068

- H069

- H070

- H071

- H072

- H073

- H074

- H075

- H076

- H077

- H078

- H079

- H080

- H081

- H082

- H083

- H084

- H085

- H086

- H087

- H088

- H089

- H090

- H091

- H092

- H093

- H094

- H095

- H096

- H097

- H098

- H099

- H100

- H101

- H102

- H103

- H104

- H105

- H106

- H107

- H108

- H109

- H110

- H111

- H112

- H113

- H114

- H115

- H116

- H117

- H118

- H119

- H120

- H121

- H122

- H123

- H124

- H125

- H126

- H127

- H128

- H129

- H130

- H131

- H132

- H133

- H134

- H135

- H136

- H137

- H138

- H139

- H140

- H141

- H142

- H143

- H144

- H145

- H146

- H147

- H148

- H149

- H150

- H151

- H152

- H153

- H154

- H155

- H156

- H157

- H158

- H159

- H160

- H161

- H162

- H163

- H164

- H165

- H166

- H167

- H168

- H169

- H170

- H171

- H172

- H173

- H174

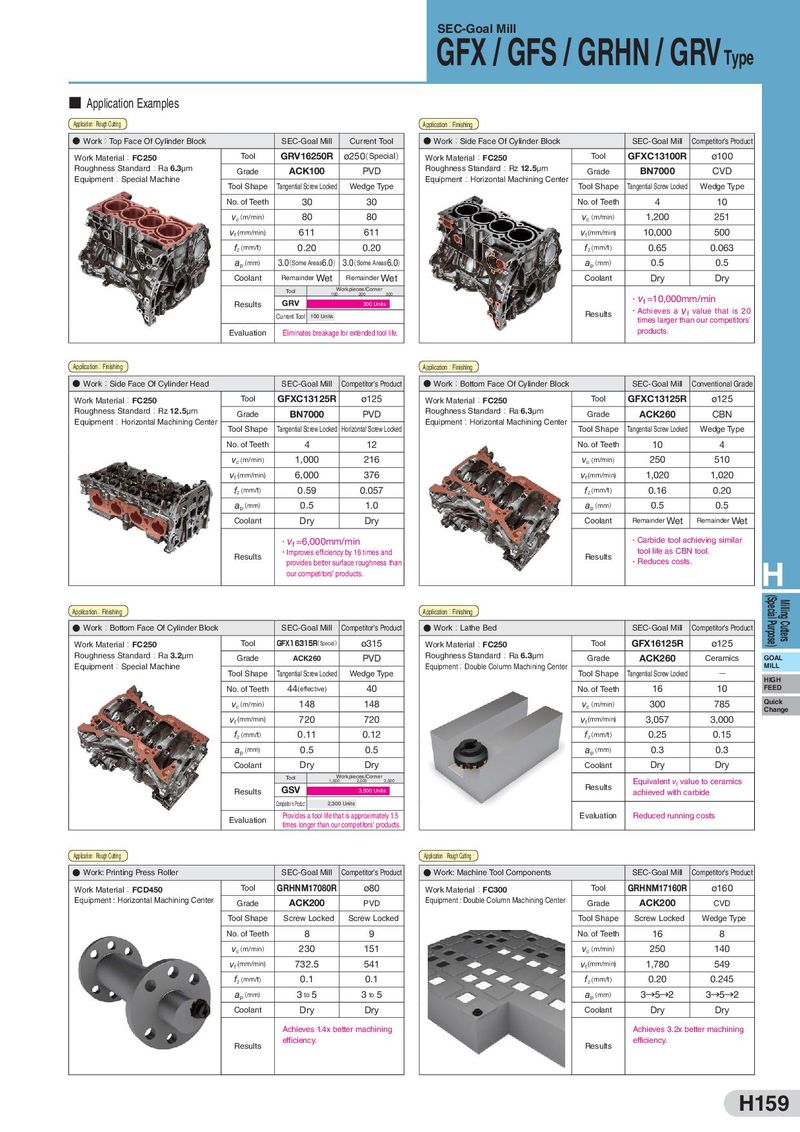

SEC-Goal Mill GFX / GFS / GRHN / GRV Type ■ Application Examples Application:Rough Cutting Application:Finishing ● Work:Top Face Of Cylinder Block SEC-Goal Mill Current Tool ● Work:Side Face Of Cylinder Block SEC-Goal Mill Competitor's Product Work Material:FC250 Tool GRV16250R ø250(Special) Work Material:FC250 Tool GFXC13100R ø100 Roughness Standard:Ra 6.3μm Grade ACK100 PVD Roughness Standard:Rz 12.5μm Grade BN7000 CVD Equipment:Special Machine Tool Shape Tangential Screw Locked Wedge Type Equipment:Horizontal Machining Center Tool Shape Tangential Screw Locked Wedge Type No. of Teeth 30 30 No. of Teeth 4 10 vc (m/min) 80 80 vc (m/min) 1,200 251 vf (mm/min) 611 611 vf (mm/min) 10,000 500 fZ (mm/t) 0.20 0.20 fZ (mm/t) 0.65 0.063 ap (mm) 3.0(Some Areas6.0) 3.0(Some Areas6.0) ap (mm) 0.5 0.5 Coolant Remainder Wet Remainder Wet Coolant Dry Dry Tool Workpieces/Corner 100 200 300 ・vf =10,000mm/min │ │ │ Results GRV 300 Units ・Achieves a vf value that is 20 Current Tool 100 Units Results times larger than our competitors' Evaluation Eliminates breakage for extended tool life. products. Application:Finishing Application:Finishing ● Work:Side Face Of Cylinder Head SEC-Goal Mill Competitor's Product ● Work:Bottom Face Of Cylinder Block SEC-Goal Mill Conventional Grade Work Material:FC250 Tool GFXC13125R ø125 Work Material:FC250 Tool GFXC13125R ø125 Roughness Standard:Rz 12.5μm Grade BN7000 PVD Roughness Standard:Ra 6.3μm Grade ACK260 CBN Equipment:Horizontal Machining Center Tool Shape Tangential Screw Locked Horizontal Screw Locked Equipment:Horizontal Machining Center Tool Shape Tangential Screw Locked Wedge Type No. of Teeth 4 12 No. of Teeth 10 4 vc (m/min) 1,000 216 vc (m/min) 250 510 vf (mm/min) 6,000 376 vf (mm/min) 1,020 1,020 fZ (mm/t) 0.59 0.057 fZ (mm/t) 0.16 0.20 ap (mm) 0.5 1.0 ap (mm) 0.5 0.5 Coolant Dry Dry Coolant Remainder Wet Remainder Wet ・vf =6,000mm/min ・Carbide tool achieving similar Results ・Improves efficiency by 16 times and Results tool life as CBN tool. provides better surface roughness than ・Reduces costs. H our competitors' products. Application:Finishing Application:Finishing (Special Purpose) Milling Cutters ● Work:Bottom Face Of Cylinder Block SEC-Goal Mill Competitor's Product ● Work:Lathe Bed SEC-Goal Mill Competitor's Product Work Material:FC250 Tool GFX16315R(Special) ø315 Work Material:FC250 Tool GFX16125R ø125 Roughness Standard:Ra 3.2μm Grade ACK260 PVD Roughness Standard:Ra 6.3μm Grade ACK260 Ceramics GOAL Equipment:Special Machine Equipment:Double Column Machining Center MILL Tool Shape Tangential Screw Locked Wedge Type Tool Shape Tangential Screw Locked ー HIGH No. of Teeth 44(effective) 40 No. of Teeth 16 10 FEED vc (m/min) 148 148 vc (m/min) 300 785 Quick Change vf (mm/min) 720 720 vf (mm/min) 3,057 3,000 fZ (mm/t) 0.11 0.12 fZ (mm/t) 0.25 0.15 ap (mm) 0.5 0.5 ap (mm) 0.3 0.3 Coolant Dry Dry Coolant Dry Dry Tool Workpieces/Corner Equivalent vf value to ceramics 1,500 2,500 3,500 │ │ │ Results Results GSV 3,500 Units achieved with carbide Competitor's Product 2,300 Units Evaluation Provides a tool life that is approximately 1.5 Evaluation Reduced running costs times longer than our competitors' products. Application:Rough Cutting Application:Rough Cutting ● Work: Printing Press Roller SEC-Goal Mill Competitor's Product ● Work: Machine Tool Components SEC-Goal Mill Competitor's Product Work Material:FCD450 Tool GRHNM17080R ø80 Work Material:FC300 Tool GRHNM17160R ø160 Equipment : Horizontal Machining Center Grade ACK200 PVD Equipment : Double Column Machining Center Grade ACK200 CVD Tool Shape Screw Locked Screw Locked Tool Shape Screw Locked Wedge Type No. of Teeth 8 9 No. of Teeth 16 8 vc (m/min) 230 151 vc (m/min) 250 140 vf (mm/min) 732.5 541 vf (mm/min) 1,780 549 fZ (mm/t) 0.1 0.1 fZ (mm/t) 0.20 0.245 ap (mm) 3 to 5 3 to 5 ap (mm) 3 5 2 3 5 2 Coolant Dry Dry Coolant Dry Dry Achieves 1.4x better machining Achieves 3.2x better machining Results efficiency. Results efficiency. H159

Техническая информация Sumitomo

Техническая информация Sumitomo Каталог Sumitomo резьбонарезной инструмент

Каталог Sumitomo резьбонарезной инструмент Каталог Sumitomo микроинструмент

Каталог Sumitomo микроинструмент Каталог Sumitomo твердосплавные заготовки

Каталог Sumitomo твердосплавные заготовки Каталог Sumitomo инструмент для отрезки

Каталог Sumitomo инструмент для отрезки Каталог Sumitomo запасные части

Каталог Sumitomo запасные части