Каталог Sumitomo резьбонарезной инструмент - страница 7

Навигация

Каталог Sumitomo фрезы со сменными пластинами

Каталог Sumitomo фрезы со сменными пластинами Каталог Sumitomo пластины с кубическим нитридом бора Sumiboron

Каталог Sumitomo пластины с кубическим нитридом бора Sumiboron Каталог Sumitomo инструмент для обработки канавок

Каталог Sumitomo инструмент для обработки канавок Общий каталог Sumitomo 2018 - 2019

Общий каталог Sumitomo 2018 - 2019 Каталог Sumitomo твердосплавные заготовки

Каталог Sumitomo твердосплавные заготовки Каталог Sumitomo модульные системы для револьверных головок токарных станков

Каталог Sumitomo модульные системы для револьверных головок токарных станков - F001

- F002

- F003

- F004

- F005

- F006

- F007

- F008

- F009

- F010

- F011

- F012

- F013

- F014

- F015

- F016

- F017

- F018

- F019

- F020

- F021

- F022

- F023

- F024

- F025

- F026

- F027

- F028

- F029

- F030

- F031

- F032

- F033

- F034

- F035

- F036

- F037

- F038

- F039

- F040

- F041

- F042

- F043

- F044

- F045

- F046

- F047

- F048

- F049

- F050

- F051

- F052

- F053

- F054

- F055

- F056

- F057

- F058

- F059

- F060

- F061

- F062

- F063

- F064

- F065

- F066

- F067

- F068

- F069

- F070

- F071

- F072

- F073

- F074

- F075

- F076

- F077

- F078

- F079

- F080

- F081

- F082

- F083

- F084

- F085

- F086

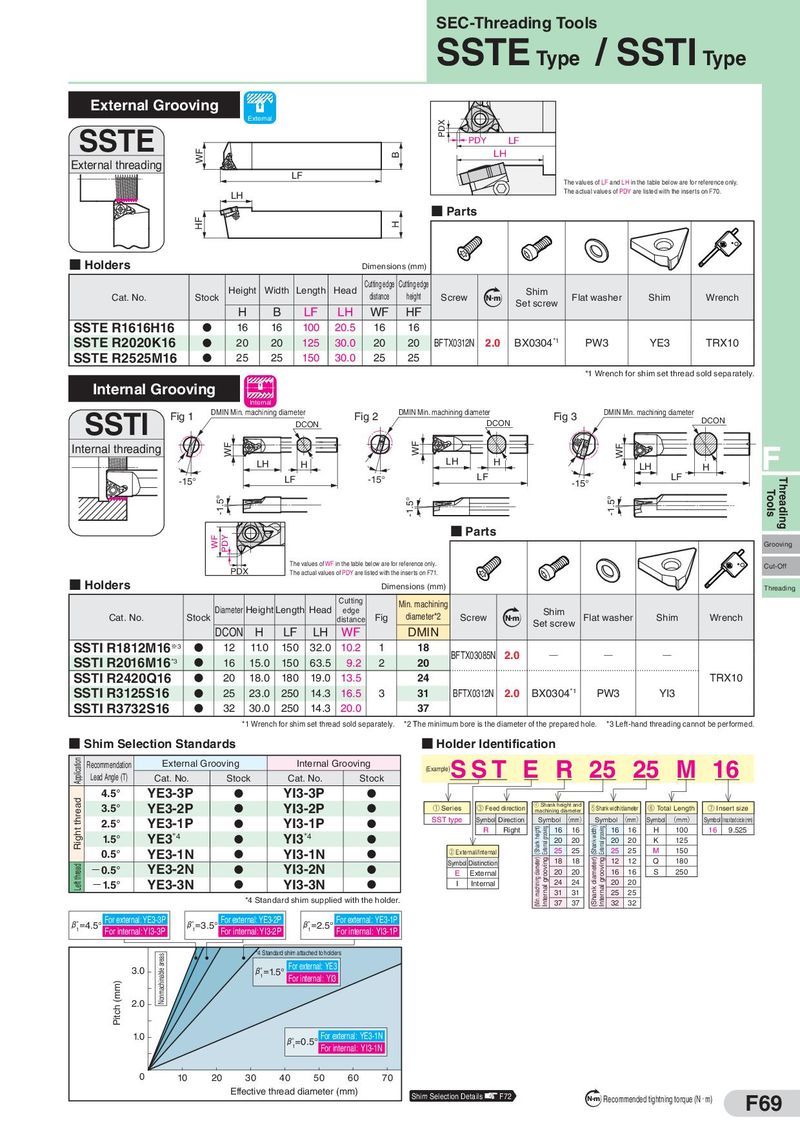

SEC-Threading Tools SSTE Type / SSTI Type External Grooving External PDX SSTE PDY LF WF B LH External threading LF The values of LF and LH in the table below are for reference only. LH The actual values of PDY are listed with the inserts on F70. HF ■ Parts H ■ Holders Dimensions (mm) Height Width Length Head Cutting edge Cutting edge Shim Cat. No. Stock distance height Screw Nm Set screw Flat washer Shim Wrench H B LF LH WF HF SSTE R1616H16 D 16 16 100 20.5 16 16 SSTE R2020K16 D 20 20 125 30.0 20 20 BFTX0312N 2.0 BX0304*1 PW3 YE3 TRX10 SSTE R2525M16 D 25 25 150 30.0 25 25 *1 Wrench for shim set thread sold separately. Internal Grooving Internal SSTI Fig 1 DMIN Min. machining diameter Fig 2 DMIN Min. machining diameter Fig 3 DMIN Min. machining diameter DCON DCON DCON Internal threading WF WF WF F LH H LH H LH H -15° LF -15° LF -15° LF Threading -1.5° -1.5° -1.5° Tools WF PDY ■ Parts Grooving The values of WF in the table below are for reference only. Cut-Off PDX The actual values of PDY are listed with the inserts on F71. ■ Holders Dimensions (mm) Threading Cutting Min. machining Cat. No. Stock Diameter Height Length Head edge Fig diameter*2 Screw Shim Flat washer Shim Wrench distance Nm Set screw DCON H LF LH WF DMIN SSTI R1812M16※3 D 12 11.0 150 32.0 10.2 1 18 BFTX03085N 2.0 Q Q Q SSTI R2016M16*3 D 16 15.0 150 63.5 9.2 2 20 SSTI R2420Q16 D 20 18.0 180 19.0 13.5 24 TRX10 SSTI R3125S16 D 25 23.0 250 14.3 16.5 3 31 BFTX0312N 2.0 BX0304*1 PW3 YI3 SSTI R3732S16 D 32 30.0 250 14.3 20.0 37 *1 Wrench for shim set thread sold separately. *2 The minimum bore is the diameter of the prepared hole. *3 Left-hand threading cannot be performed. ■ Shim Selection Standards ■ Holder Identification Application Recommendation External Grooving Internal Grooving S S T (Example) E R 25 25 M 16 Lead Angle (T) Cat. No. Stock Cat. No. Stock Right thread 4.5° YE3-3P D YI3-3P D 3.5° YE3-2P D YI3-2P D ① Series ③ Feed direction ④ Shank height and ⑤ Shank width/diameter ⑥ Total Length ⑦ Insert size machining diameter 2.5° YE3-1P D YI3-1P D SST type Symbol Direction Symbol (mm) Symbol (mm) Symbol (mm) Symbol Inscribed circle (mm) YE3*4 YI3*4 R Right (Shank height) External grooving 16 16 (Shank width) External grooving 16 16 H 100 16 9.525 1.5° D D 20 20 20 20 K 125 0.5° YE3-1N D YI3-1N D ② External/Internal 25 25 25 25 M 150 Left thread YE3-2N YI3-2N Symbol Distinction (Min. machining diameter) Internal grooving 18 18 (Shank diameter) Internal grooving 12 12 Q 180 −0.5° D D E External 20 20 16 16 S 250 −1.5° YE3-3N D YI3-3N D I Internal 24 24 20 20 31 31 25 25 *4 Standard shim supplied with the holder. 37 37 32 32 T1 4.5° For external: YE3-3P T1 3.5° For external: YE3-2P T1 2.5° For external: YE3-1P For internal: YI3-3P For internal: YI3-2P For internal: YI3-1P Nonmachinable areas *4 Standard shim attached to holders D D D 3.0 T1 1.5° For external: YE3 Pitch (mm) For internal: YI3 2.0 1.0 T1 0.5° For external: YE3-1N For internal: YI3-1N 0 10 20 30 40 50 60 70 Effective thread diameter (mm) Shim Selection Details F72 N m Recommended tightning torque (N・m) F69