Каталог Sumitomo резьбонарезной инструмент - страница 10

Навигация

Каталог Sumitomo фрезы со сменными пластинами

Каталог Sumitomo фрезы со сменными пластинами Каталог Sumitomo пластины с кубическим нитридом бора Sumiboron

Каталог Sumitomo пластины с кубическим нитридом бора Sumiboron Каталог Sumitomo инструмент для обработки канавок

Каталог Sumitomo инструмент для обработки канавок Общий каталог Sumitomo 2018 - 2019

Общий каталог Sumitomo 2018 - 2019 Каталог Sumitomo твердосплавные заготовки

Каталог Sumitomo твердосплавные заготовки Каталог Sumitomo модульные системы для револьверных головок токарных станков

Каталог Sumitomo модульные системы для револьверных головок токарных станков - F001

- F002

- F003

- F004

- F005

- F006

- F007

- F008

- F009

- F010

- F011

- F012

- F013

- F014

- F015

- F016

- F017

- F018

- F019

- F020

- F021

- F022

- F023

- F024

- F025

- F026

- F027

- F028

- F029

- F030

- F031

- F032

- F033

- F034

- F035

- F036

- F037

- F038

- F039

- F040

- F041

- F042

- F043

- F044

- F045

- F046

- F047

- F048

- F049

- F050

- F051

- F052

- F053

- F054

- F055

- F056

- F057

- F058

- F059

- F060

- F061

- F062

- F063

- F064

- F065

- F066

- F067

- F068

- F069

- F070

- F071

- F072

- F073

- F074

- F075

- F076

- F077

- F078

- F079

- F080

- F081

- F082

- F083

- F084

- F085

- F086

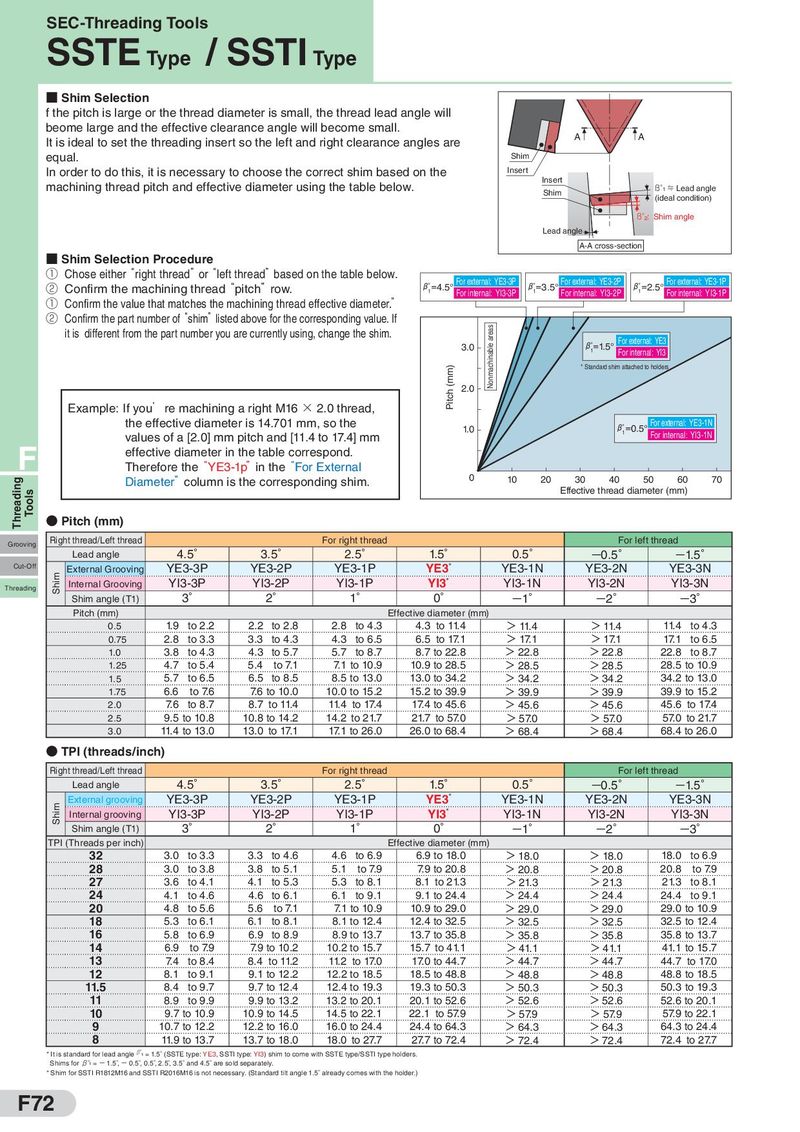

SEC-Threading Tools SSTE Type / SSTI Type ■ Shim Selection f the pitch is large or the thread diameter is small, the thread lead angle will beome large and the effective clearance angle will become small. A A It is ideal to set the threading insert so the left and right clearance angles are equal. Shim In order to do this, it is necessary to choose the correct shim based on the Insert machining thread pitch and effective diameter using the table below. Insert Shim ß°1 ≒ Lead angle (ideal condition) ß°2: Shim angle Lead angle A-A cross-section ■ Shim Selection Procedure ① Chose either right thread or left thread based on the table below. For external: YE3-3P For external: YE3-2P For external: YE3-1P ② Confirm the machining thread pitch row. T1 4.5° For internal: YI3-3P T1 3.5° For internal: YI3-2P T1 2.5° For internal: YI3-1P ① Confirm the value that matches the machining thread effective diameter. ② Confirm the part number of shim listed above for the corresponding value. If it is different from the part number you are currently using, change the shim. Nonmachinable areas D D D 3.0 T1 1.5° For external: YE3 For internal: YI3 Pitch (mm) * Standard shim attached to holders 2.0 Example: If you re machining a right M16 × 2.0 thread, the effective diameter is 14.701 mm, so the 1.0 T1 0.5° For external: YE3-1N values of a [2.0] mm pitch and [11.4 to 17.4] mm For internal: YI3-1N F effective diameter in the table correspond. Therefore the YE3-1p in the For External Threading Diameter column is the corresponding shim. 0 10 20 30 40 50 60 70 Tools Effective thread diameter (mm) ● Pitch (mm) Grooving Right thread/Left thread For right thread For left thread Lead angle 4.5° 3.5° 2.5° 1.5° 0.5° −0.5° −1.5° Cut-Off External Grooving YE3-3P YE3-2P YE3-1P YE3* YE3-1N YE3-2N YE3-3N Threading Shim Internal Grooving YI3-3P YI3-2P YI3-1P YI3* YI3-1N YI3-2N YI3-3N Shim angle (T1) 3° 2° 1° 0° −1° −2° −3° Pitch (mm) Effective diameter (mm) 0.5 1.9 to 2.2 2.2 to 2.8 2.8 to 4.3 4.3 to 11.4 > 11.4 > 11.4 11.4 to 4.3 0.75 2.8 to 3.3 3.3 to 4.3 4.3 to 6.5 6.5 to 17.1 > 17.1 > 17.1 17.1 to 6.5 1.0 3.8 to 4.3 4.3 to 5.7 5.7 to 8.7 8.7 to 22.8 > 22.8 > 22.8 22.8 to 8.7 1.25 4.7 to 5.4 5.4 to 7.1 7.1 to 10.9 10.9 to 28.5 > 28.5 > 28.5 28.5 to 10.9 1.5 5.7 to 6.5 6.5 to 8.5 8.5 to 13.0 13.0 to 34.2 > 34.2 > 34.2 34.2 to 13.0 1.75 6.6 to 7.6 7.6 to 10.0 10.0 to 15.2 15.2 to 39.9 > 39.9 > 39.9 39.9 to 15.2 2.0 7.6 to 8.7 8.7 to 11.4 11.4 to 17.4 17.4 to 45.6 > 45.6 > 45.6 45.6 to 17.4 2.5 9.5 to 10.8 10.8 to 14.2 14.2 to 21.7 21.7 to 57.0 > 57.0 > 57.0 57.0 to 21.7 3.0 11.4 to 13.0 13.0 to 17.1 17.1 to 26.0 26.0 to 68.4 > 68.4 > 68.4 68.4 to 26.0 ● TPI (threads/inch) Right thread/Left thread For right thread For left thread Lead angle 4.5° 3.5° 2.5° 1.5° 0.5° −0.5° −1.5° Shim External grooving YE3-3P YE3-2P YE3-1P YE3* YE3-1N YE3-2N YE3-3N Internal grooving YI3-3P YI3-2P YI3-1P YI3* YI3-1N YI3-2N YI3-3N Shim angle (T1) 3° 2° 1° 0° −1° −2° −3° TPI (Threads per inch) Effective diameter (mm) 32 3.0 to 3.3 3.3 to 4.6 4.6 to 6.9 6.9 to 18.0 > 18.0 > 18.0 18.0 to 6.9 28 3.0 to 3.8 3.8 to 5.1 5.1 to 7.9 7.9 to 20.8 > 20.8 > 20.8 20.8 to 7.9 27 3.6 to 4.1 4.1 to 5.3 5.3 to 8.1 8.1 to 21.3 > 21.3 > 21.3 21.3 to 8.1 24 4.1 to 4.6 4.6 to 6.1 6.1 to 9.1 9.1 to 24.4 > 24.4 > 24.4 24.4 to 9.1 20 4.8 to 5.6 5.6 to 7.1 7.1 to 10.9 10.9 to 29.0 > 29.0 > 29.0 29.0 to 10.9 18 5.3 to 6.1 6.1 to 8.1 8.1 to 12.4 12.4 to 32.5 > 32.5 > 32.5 32.5 to 12.4 16 5.8 to 6.9 6.9 to 8.9 8.9 to 13.7 13.7 to 35.8 > 35.8 > 35.8 35.8 to 13.7 14 6.9 to 7.9 7.9 to 10.2 10.2 to 15.7 15.7 to 41.1 > 41.1 > 41.1 41.1 to 15.7 13 7.4 to 8.4 8.4 to 11.2 11.2 to 17.0 17.0 to 44.7 > 44.7 > 44.7 44.7 to 17.0 12 8.1 to 9.1 9.1 to 12.2 12.2 to 18.5 18.5 to 48.8 > 48.8 > 48.8 48.8 to 18.5 11.5 8.4 to 9.7 9.7 to 12.4 12.4 to 19.3 19.3 to 50.3 > 50.3 > 50.3 50.3 to 19.3 11 8.9 to 9.9 9.9 to 13.2 13.2 to 20.1 20.1 to 52.6 > 52.6 > 52.6 52.6 to 20.1 10 9.7 to 10.9 10.9 to 14.5 14.5 to 22.1 22.1 to 57.9 > 57.9 > 57.9 57.9 to 22.1 9 10.7 to 12.2 12.2 to 16.0 16.0 to 24.4 24.4 to 64.3 > 64.3 > 64.3 64.3 to 24.4 8 11.9 to 13.7 13.7 to 18.0 18.0 to 27.7 27.7 to 72.4 > 72.4 > 72.4 72.4 to 27.7 * It is standard for lead angle Y1 = 1.5°(SSTE type: YE3, SSTI type: YI3) shim to come with SSTE type/SSTI type holders. Shims for β°1 = − 1.5°, − 0.5°, 0.5°, 2.5°, 3.5°and 4.5°are sold separately. * Shim for SSTI R1812M16 and SSTI R2016M16 is not necessary. (Standard tilt angle 1.5°already comes with the holder.) F72