Каталог Sumitomo резьбонарезной инструмент - страница 11

Навигация

Каталог Sumitomo фрезы со сменными пластинами

Каталог Sumitomo фрезы со сменными пластинами Каталог Sumitomo пластины с кубическим нитридом бора Sumiboron

Каталог Sumitomo пластины с кубическим нитридом бора Sumiboron Каталог Sumitomo инструмент для обработки канавок

Каталог Sumitomo инструмент для обработки канавок Общий каталог Sumitomo 2018 - 2019

Общий каталог Sumitomo 2018 - 2019 Каталог Sumitomo твердосплавные заготовки

Каталог Sumitomo твердосплавные заготовки Каталог Sumitomo модульные системы для револьверных головок токарных станков

Каталог Sumitomo модульные системы для револьверных головок токарных станков - F001

- F002

- F003

- F004

- F005

- F006

- F007

- F008

- F009

- F010

- F011

- F012

- F013

- F014

- F015

- F016

- F017

- F018

- F019

- F020

- F021

- F022

- F023

- F024

- F025

- F026

- F027

- F028

- F029

- F030

- F031

- F032

- F033

- F034

- F035

- F036

- F037

- F038

- F039

- F040

- F041

- F042

- F043

- F044

- F045

- F046

- F047

- F048

- F049

- F050

- F051

- F052

- F053

- F054

- F055

- F056

- F057

- F058

- F059

- F060

- F061

- F062

- F063

- F064

- F065

- F066

- F067

- F068

- F069

- F070

- F071

- F072

- F073

- F074

- F075

- F076

- F077

- F078

- F079

- F080

- F081

- F082

- F083

- F084

- F085

- F086

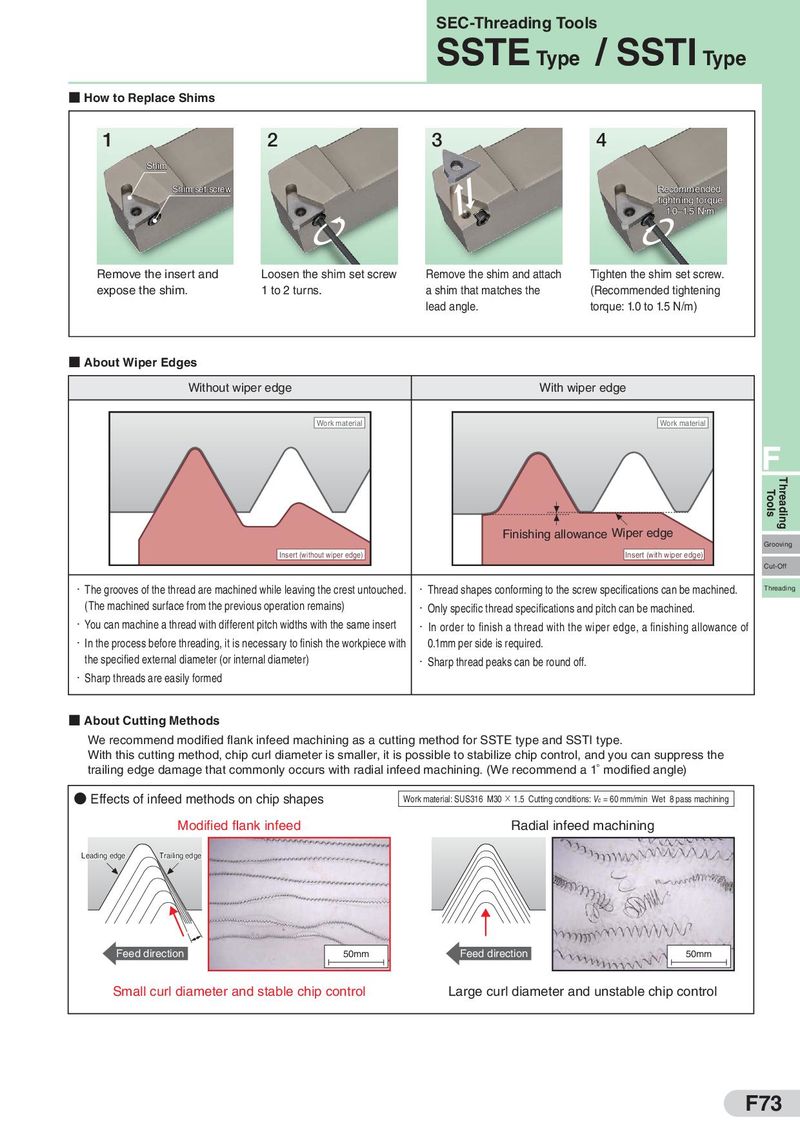

SEC-Threading Tools SSTE Type / SSTI Type ■ How to Replace Shims 1 2 3 4 Shim Shim set screw Recommended tightning torque 1.0–1.5 N・m Remove the insert and Loosen the shim set screw Remove the shim and attach Tighten the shim set screw. expose the shim. 1 to 2 turns. a shim that matches the (Recommended tightening lead angle. torque: 1.0 to 1.5 N/m) ■ About Wiper Edges Without wiper edge With wiper edge Work material Work material F Tools Threading Finishing allowance Wiper edge Grooving Insert (without wiper edge) Insert (with wiper edge) Cut-Off ・The grooves of the thread are machined while leaving the crest untouched. ・Thread shapes conforming to the screw speci cations can be machined. Threading (The machined surface from the previous operation remains) ・Only speci c thread speci cations and pitch can be machined. ・You can machine a thread with different pitch widths with the same insert ・In order to nish a thread with the wiper edge, a nishing allowance of ・In the process before threading, it is necessary to nish the workpiece with 0.1mm per side is required. the speci ed external diameter (or internal diameter) ・Sharp thread peaks can be round off. ・Sharp threads are easily formed ■ About Cutting Methods We recommend modified flank infeed machining as a cutting method for SSTE type and SSTI type. With this cutting method, chip curl diameter is smaller, it is possible to stabilize chip control, and you can suppress the trailing edge damage that commonly occurs with radial infeed machining. (We recommend a 1°modified angle) ● Effects of infeed methods on chip shapes Work material: SUS316 M30 × 1.5 Cutting conditions: Vc = 60 mm/min Wet 8 pass machining Modi ed flank infeed Radial infeed machining Leading edge Trailing edge Feed direction 50mm Feed direction 50mm Small curl diameter and stable chip control Large curl diameter and unstable chip control F73