Каталог Sumitomo резьбонарезной инструмент - страница 6

Навигация

Каталог Sumitomo фрезы со сменными пластинами

Каталог Sumitomo фрезы со сменными пластинами Каталог Sumitomo пластины с кубическим нитридом бора Sumiboron

Каталог Sumitomo пластины с кубическим нитридом бора Sumiboron Каталог Sumitomo инструмент для обработки канавок

Каталог Sumitomo инструмент для обработки канавок Общий каталог Sumitomo 2018 - 2019

Общий каталог Sumitomo 2018 - 2019 Каталог Sumitomo твердосплавные заготовки

Каталог Sumitomo твердосплавные заготовки Каталог Sumitomo модульные системы для револьверных головок токарных станков

Каталог Sumitomo модульные системы для револьверных головок токарных станков - F001

- F002

- F003

- F004

- F005

- F006

- F007

- F008

- F009

- F010

- F011

- F012

- F013

- F014

- F015

- F016

- F017

- F018

- F019

- F020

- F021

- F022

- F023

- F024

- F025

- F026

- F027

- F028

- F029

- F030

- F031

- F032

- F033

- F034

- F035

- F036

- F037

- F038

- F039

- F040

- F041

- F042

- F043

- F044

- F045

- F046

- F047

- F048

- F049

- F050

- F051

- F052

- F053

- F054

- F055

- F056

- F057

- F058

- F059

- F060

- F061

- F062

- F063

- F064

- F065

- F066

- F067

- F068

- F069

- F070

- F071

- F072

- F073

- F074

- F075

- F076

- F077

- F078

- F079

- F080

- F081

- F082

- F083

- F084

- F085

- F086

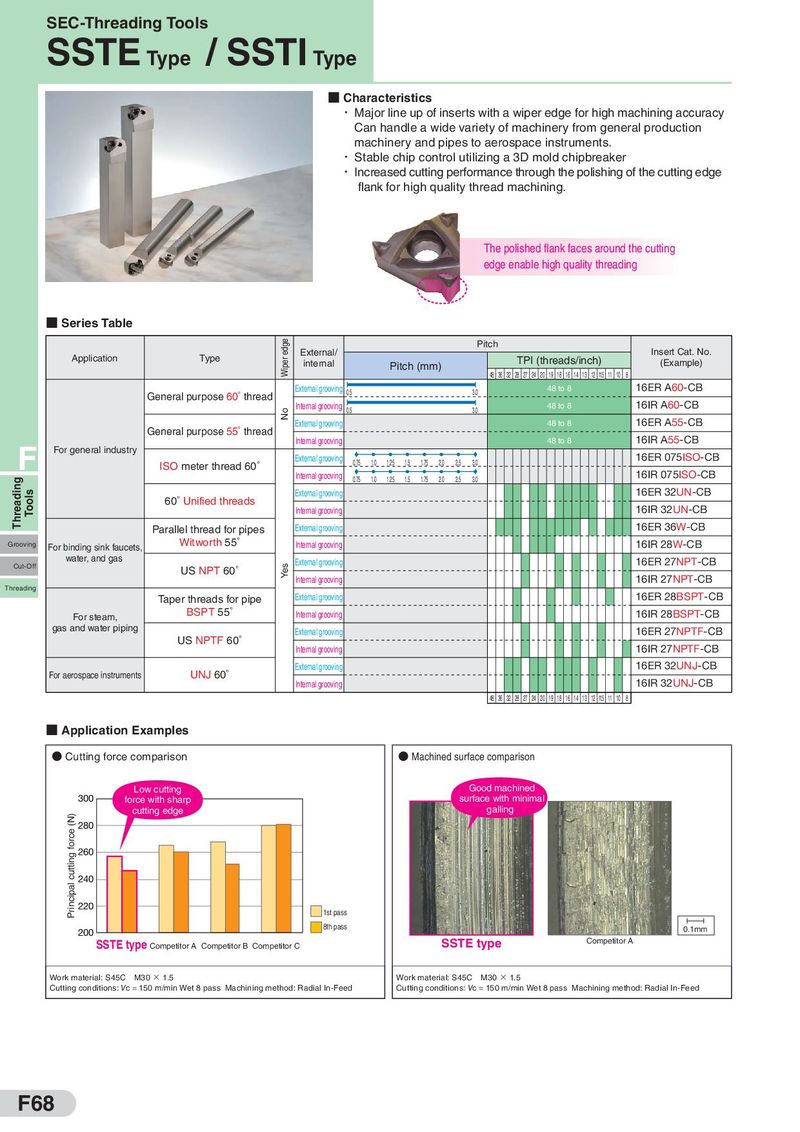

SEC-Threading Tools SSTE Type / SSTI Type ■ Characteristics ・ Major line up of inserts with a wiper edge for high machining accuracy Can handle a wide variety of machinery from general production machinery and pipes to aerospace instruments. ・ Stable chip control utilizing a 3D mold chipbreaker ・ Increased cutting performance through the polishing of the cutting edge flank for high quality thread machining. The polished flank faces around the cutting edge enable high quality threading ■ Series Table Wiper edge External/ Pitch Insert Cat. No. Application Type internal Pitch (mm) TPI (threads/inch) (Example) 48 36 32 28 27 24 20 19 18 16 14 13 12 11.5 11 10 8 External grooving 0.5 3.0 48 to 8 16ER A60-CB General purpose 60°thread Internal grooving 16IR A60-CB No 0.5 3.0 48 to 8 External grooving 48 to 8 16ER A55-CB General purpose 55°thread Internal grooving 16IR A55-CB 48 to 8 F For general industry External grooving 16ER 075ISO-CB ISO meter thread 60° 0.75 1.0 1.25 1.5 1.75 2.0 2.5 3.0 Threading Internal grooving 0.75 1.0 1.25 1.5 1.75 2.0 2.5 3.0 16IR 075ISO-CB Tools External grooving 16ER 32UN-CB 60°Unified threads Internal grooving 16IR 32UN-CB Parallel thread for pipes External grooving 16ER 36W-CB Grooving For binding sink faucets, Witworth 55° Internal grooving 16IR 28W-CB water, and gas Yes External grooving 16ER 27NPT-CB Cut-Off US NPT 60° Internal grooving 16IR 27NPT-CB Threading 16ER 28BSPT-CB Taper threads for pipe External grooving For steam, BSPT 55° Internal grooving 16IR 28BSPT-CB gas and water piping External grooving 16ER 27NPTF-CB US NPTF 60° Internal grooving 16IR 27NPTF-CB External grooving 16ER 32UNJ-CB For aerospace instruments UNJ 60° 16IR 32UNJ-CB Internal grooving 48 36 32 28 27 24 20 19 18 16 14 13 12 11.5 11 10 8 ■ Application Examples ● Cutting force comparison ● Machined surface comparison Low cutting Good machined 300 force with sharp surface with minimal Principal cutting force (N) cutting edge galling 280 260 240 220 1st pass 200 8th pass 0.1mm SSTE type Competitor A Competitor B Competitor C SSTE type Competitor A Work material: S45C M30 × 1.5 Work material: S45C M30 × 1.5 Cutting conditions: Vc = 150 m/min Wet 8 pass Machining method: Radial In-Feed Cutting conditions: Vc = 150 m/min Wet 8 pass Machining method: Radial In-Feed F68