Общий каталог Mitsubishi 2020 - 2021 - страница 988

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

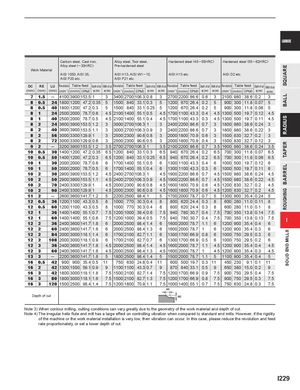

SQUAREBALLRADIUSTAPERBARRELROUGHINGSOLID END MILLS CARBIDE Carbon steel, Cast iron, Alloy steel, Tool steel, Hardened steel (45 ─55HRC) Hardened steel (55─ 62HRC) Alloy steel (─30HRC) Pre-hardened steel Work Material AISI 1050, AISI 35, AISI H13, AISI W1─10, AISI H13 etc. AISI D2 etc. AISI P20 etc. AISI P21 etc. DC RE LU Revolution Table feed Depth of cut Width of cut Revolution Table feed Depth of cut Width of cut Revolution Table feed Depth of cut Width of cut Revolution Table feed Depth of cut Width of cut (mm) (mm) (mm) (min-1) (mm/min) (IPM) ap (mm) ae (mm) (min-1) (mm/min) (IPM) ap (mm) ae (mm) (min-1) (mm/min) (IPM) ap (mm) ae (mm) (min-1) (mm/min) (IPM) ap (mm) ae (mm) 7 1.5 ― 4100 3900 153.5 1 3 3400 2700 106.3 0.8 3 2700 2200 86.6 0.6 3 2100 980 38.6 0.2 3 8 0.5 24 1800 1200 47.2 0.35 5 1500 840 33.1 0.3 5 1200 670 26.4 0.2 5 900 300 11.8 0.07 5 8 0.5 40 1800 1200 47.2 0.3 5 1500 840 33.1 0.25 5 1200 670 26.4 0.2 5 900 300 11.8 0.06 5 8 1 24 2500 2000 78.7 0.6 4.5 2100 1400 55.1 0.5 4.5 1700 1100 43.3 0.4 4.5 1300 500 19.7 0.12 4.5 8 1 40 2500 2000 78.7 0.5 4.5 2100 1400 55.1 0.4 4.5 1700 1100 43.3 0.3 4.5 1300 500 19.7 0.11 4.5 8 2 24 3600 3900 153.5 1.2 3 3000 2700 106.3 1 3 2400 2200 86.6 0.7 3 1800 980 38.6 0.24 3 8 2 40 3600 3900 153.5 1.1 3 3000 2700 106.3 0.9 3 2400 2200 86.6 0.7 3 1800 980 38.6 0.22 3 8 2 56 3000 3300 129.9 1 3 2500 2300 90.6 0.8 3 2000 1800 70.9 0.6 3 1500 830 32.7 0.2 3 8 2 72 3000 3300 129.9 0.6 3 2500 2300 90.6 0.5 3 2000 1800 70.9 0.4 3 1500 830 32.7 0.12 3 9 2 ― 3200 3900 153.5 1.2 3.5 2700 2700 106.3 1 3.5 2100 2200 86.6 0.7 3.5 1600 980 38.6 0.24 3.5 10 0.5 30 1400 1200 47.2 0.35 6.5 1200 840 33.1 0.3 6.5 940 670 26.4 0.2 6.5 700 300 11.8 0.07 6.5 10 0.5 50 1400 1200 47.2 0.3 6.5 1200 840 33.1 0.25 6.5 940 670 26.4 0.2 6.5 700 300 11.8 0.06 6.5 10 1 30 2000 2000 78.7 0.6 6 1700 1400 55.1 0.5 6 1300 1100 43.3 0.4 6 1000 500 19.7 0.12 6 10 1 50 2000 2000 78.7 0.5 6 1700 1400 55.1 0.4 6 1300 1100 43.3 0.3 6 1000 500 19.7 0.11 6 10 2 30 2900 3900 153.5 1.2 4.5 2400 2700 106.3 1 4.5 1900 2200 86.6 0.7 4.5 1500 980 38.6 0.24 4.5 10 2 50 2900 3900 153.5 1.1 4.5 2400 2700 106.3 0.9 4.5 1900 2200 86.6 0.7 4.5 1500 980 38.6 0.22 4.5 10 2 70 2400 3300 129.9 1 4.5 2000 2300 90.6 0.8 4.5 1600 1800 70.9 0.6 4.5 1200 830 32.7 0.2 4.5 10 2 90 2400 3300 129.9 1 4.5 2000 2300 90.6 0.8 4.5 1600 1800 70.9 0.6 4.5 1200 830 32.7 0.2 4.5 11 2 ― 2600 3600 141.7 1.2 5 2200 2500 98.4 1 5 1700 2000 78.7 0.7 5 1300 900 35.4 0.24 5 12 0.5 36 1200 1100 43.3 0.5 8 1000 770 30.3 0.4 8 800 620 24.4 0.3 8 600 280 11.0 0.11 8 12 0.5 60 1200 1100 43.3 0.5 8 1000 770 30.3 0.4 8 800 620 24.4 0.3 8 600 280 11.0 0.1 8 12 1 36 1400 1400 55.1 0.7 7.5 1200 1000 39.4 0.6 7.5 940 780 30.7 0.4 7.5 700 350 13.8 0.14 7.5 12 1 60 1400 1400 55.1 0.6 7.5 1200 1000 39.4 0.5 7.5 940 780 30.7 0.4 7.5 700 350 13.8 0.13 7.51223624003600 141.71.862000 250098.4 1.461600 200078.71.16120090035.40.46I 12 2 60 2400 3600 141.7 1.6 6 2000 2500 98.4 1.3 6 1600 2000 78.7 1 6 1200 900 35.4 0.3 6 12 2 84 2000 3000 118.1 1.4 6 1700 2100 82.7 1.1 6 1300 1700 66.9 0.8 6 1000 750 29.5 0.3 6 12 2 108 2000 3000 118.1 0.9 6 1700 2100 82.7 0.7 6 1300 1700 66.9 0.5 6 1000 750 29.5 0.2 6 12 3 36 2400 3600 141.7 1.8 4.5 2000 2500 98.4 1.4 4.5 1600 2000 78.7 1.1 4.5 1200 900 35.4 0.4 4.5 12 3 60 2400 3600 141.7 1.6 4.5 2000 2500 98.4 1.3 4.5 1600 2000 78.7 1 4.5 1200 900 35.4 0.3 4.5 13 3 ― 2200 3600 141.7 1.8 5 1800 2500 98.4 1.4 5 1500 2000 78.7 1.1 5 1100 900 35.4 0.4 5 16 0.5 42 900 900 35.4 0.5 11 750 630 24.8 0.4 11 600 500 19.7 0.3 11 450 230 9.1 0.1 11 16 2 42 1300 1500 59.1 0.9 9 1100 1100 43.3 0.7 9 870 840 33.1 0.5 9 650 380 15.0 0.2 9 16 3 42 1800 3000 118.1 1.8 7.5 1500 2100 82.7 1.4 7.5 1200 1700 66.9 0.9 7.5 900 750 29.5 0.4 7.5 16 3 80 1800 3000 118.1 1.6 7.5 1500 2100 82.7 1.3 7.5 1200 1700 66.9 0.8 7.5 900 750 29.5 0.3 7.5 16 3 120 1500 2500 98.4 1.4 7.5 1200 1800 70.9 1.1 7.5 1000 1400 55.1 0.7 7.5 750 630 24.8 0.3 7.5 ae Depth of cut Note 3) When contour milling, cutting conditions can vary greatly due to the geometry of the work material and depth of cut. Note 4) The irregular helix flute end mill has a large effect on controlling vibration when compared to standard end mills. However, if the rigidity of the machine or the work material installation is very low, then vibration can occur. In this case, please reduce the revolution and feed rate proportionately, or set a lower depth of cut. I229