Общий каталог Mitsubishi 2020 - 2021 - страница 39

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

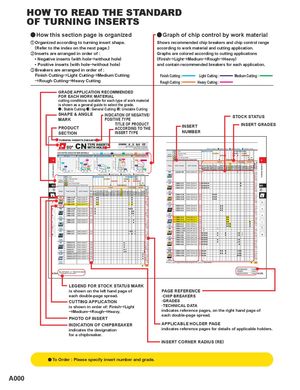

TURNING INSERTS Depth of Cut (inch) Depth of Cut (inch) UE6105 Depth of Cut (inch)UE6110 MC6015 MC6025 MC6035 UH6400 MS6015 MC7015 MC7025 MP7035 US735 US905 MC5005 Depth of Cut (inch)MC5015 UC5105 UC5115 MP9005 MP9015 MP9025 VP05RT VP10RT VP15TF UP20M NX2525 NX3035 Depth of Cut (inch)MP3025 AP25N VP25N UTi20T HTi05T HTi10 MT9015 RT9005 RT9010 Applicable Holder Page UE6105 UE6110 MC6015 MC6025 MC6035 UH6400 MS6015 MC7015 MC7025 MP7035 US735 US905 MC5005 MC5015 UC5105 UC5115 MP9005 MP9015 MP9025 VP05RT VP10RT VP15TF UP20M NX2525 NX3035 MP3025 AP25N VP25N UTi20T HTi05T HTi10 MT9015 RT9005 RT9010 Applicable Holder Page TURNING INSERTS HOW TO READ THE STANDARD OF TURNING INSERTS aHow this section page is organized aGraph of chip control by work material zOrganized according to turning insert shape. Shows recommended chip breakers and chip control range (Refer to the index on the next page.) according to work material and cutting application. xInserts are arranged in order of : Graphs are colored according to cutting applications • Negative inserts (with hole|without hole) (Finish|Light|Medium|Rough|Heavy) • Positive inserts (with hole|without hole) and contain recommended breakers for each application. cBreakers are arranged in order of : Finish Cutting|Light Cutting|Medium Cutting Finish Cutting : Light Cutting : Medium Cutting : |Rough Cutting|Heavy Cutting Rough Cutting : Heavy Cutting : GRADE APPLICATION RECOMMENDED FOR EACH WORK MATERIAL cutting conditions suitable for each type of work material is shown as a general guide to select the grade. : Stable Cutting : General Cutting : Unstable Cutting SHAPE & ANGLE INDICATION OF NEGATIVE/MARKPOSITIVE TYPE STOCK STATUS PRODUCTSECTION TITLE OF PRODUCTACCORDING TO THEINSERT TYPE INSERTNUMBER INSERT GRADES TURNING INSERTS [NEGATIVE] 80° CN TYPE WITH INSERTS HOLE CNMG 4 3 0.5 FPSizeThicknessCorner RadiusChip Breaker*Please refer to page A002. Cutting Conditions : Stable Cutting General Cutting Unstable Cutting P Steel CHIP CONTROL RANGE FOR WORK MATERIALS Finish Cutting Light Cutting Medium Cutting Rough Cutting Heavy Cutting M Stainless Steel Mild Steel Carbon Steel·Alloy Steel Carbon Steel·Alloy Steel (Wiper) Stainless Steel (<200HB) Cast Iron (<350MPa) WorkMaterial K Cast Iron N Non-Ferrous Metal A HXFYFP MM HL RK Flat TopRM S Heat-resistant Alloy, Titanium Alloy Coated Cermet Coated Cermet Carbide A LP SWSYRP LK Shape Order Number (ISO) Number RE MWMP LM MK (inch) Feed (inch/rev) Feed (inch/rev) Feed (inch/rev) Feed (inch/rev) Feed (inch/rev) PK CNGG431PK CNGG120404-PK .016 s C006 Cutting Conditions : Stable Cutting General Cutting Unstable Cutting ─ 009 E021 P Steel E024 M Stainless SteelWorkMaterialKCast Iron H006FinishCutting─ 008 N Non-Ferrous Metal LP CNMG431LP CNMG120404-LP .016 a a a a a a C006 NEG S Heat-resistant Alloy, Titanium Alloy CNMG432LP CNMG120408-LP .031 a a a a a a ─ 009 NEG Coated Cermet Coated Cermet Carbide CNMG433LP CNMG120412-LP .047 a a a a aWITHHOLEShapeOrder Number(ISO) NumberRELightCutting E021E024H006─ 008 WITHHOLE (inch) LM CNMG431LM CNMG120404-LM .016 aaa C006 FP CNMG430.5FP CNMG120402-FP .008 aaCNMG431FPCNMG120404-FP.016aa s a C006sa─ 009 CNMG432LM CNMG120408-LM .031 aaaCNMG433LMCNMG120412-LM.047aaa ─ 009E021E024 CNMG432FP CNMG120408-FP .031 aaCNMG433FPCNMG120412-FP.047aa s a E021E024saH006 LightCutting H006─ 008 FinishCutting ─ 008 LK CNMG431LK CNMG120404-LK .016 aa C006 FH CNMG430.5FH CNMG120402-FH .008 aCNMG431FHCNMG120404-FH.016a a a a C006saa─ 009 CNMG432LK CNMG120408-LK .031 aaCNMG433LKCNMG120412-LK.047aa ─ 009E021E024 CNMG432FH CNMG120408-FH .031 aCNMG433FHCNMG120412-FH.047 s aa E021E024ssH006 LightCutting H006─ 008 FinishCutting ─ 008 LS CNMG321LS CNMG090304-LS .016 aa C006 FS CNMG431FS CNMG120404-FS .016CNMG432FSCNMG120408-FS.031 s a C006sa─ 009 CNMG322LS CNMG090308-LS .031 aa ─ 009CNMG430.5LSCNMG120402-LS.008aaaE021E024 E021E024H006 Light CNMG431LS CNMG120404-LS .016CuttingCNMG432LSCNMG120408-LS.031 aaa a H006aaaa─ 008 FinishCutting ─ 008 SH CNMG32.51SH CNMG09T304-SH .016 s s C006 FY CNMG431FY CNMG120404-FY .016CNMG432FYCNMG120408-FY.031 s a a s C006sas─ 009 CNMG32.52SH CNMG09T308-SH .031 s ─ 009CNMG431SHCNMG120404-SH.016 a a a aaasasE021E024 E021 CNMG432SH CNMG120408-SH .031 a a a a a a sa s H006 E024H006 LightCuttingCNMG433SH CNMG120412-SH .047 a a a a ─ 008 FinishCutting ─ 008 SA CNMG431SA CNMG120404-SA .016 a a a a a sa C006 FJ CNGG43V5FJ CNGG1204V5-FJ .002CNGG430.2FJCNGG120401-FJ.004 a s C006as ─ 009 CNMG432SA CNMG120408-SA .031 a a a a a sa ─ 009CNMG433SACNMG120412-SA.047 a a a aaE021E024 CNGG430.5FJ CNGG120402-FJ .008 a s E021E024 LightCNGG431FJCNGG120404-FJ.016ass H006Cutting H006─ 008 FinishCutting CNGG432FJ CNGG120408-FJ .031FJ-PCNGG430.2FJ-P CNGG120401-FJ-P.004CNGG430.5FJ-P CNGG120402-FJ-P.008 aa a ─ 008aC006a─ 009 SW(With Wiper) * CNMG431SW*CNMG432SWCNMG120404-SW .016 a a aCNMG120408-SW.031 a a a*CNMG433SWCNMG120412-SW.047 a a aaaa sa a C006aaasa a─ 009aa aE021E024 CNGG43V5FJ-P CNGG1204V5-FJ-P .002 a E021E024 LightH006Cutting H006─ 008 FinishCutting ─ 008 Please refer to page A032 before using the SW breaker (wiper insert). a = a = CHIP BREAKER A046 a : USA Stock s : Stocked in Japan GRADES A034 A104 <10 inserts in one case> IDENTIFICATION A002 A105 LEGEND FOR STOCK STATUS MARK is shown on the left hand page of PAGE REFERENCE each double-page spread. ·CHIP BREAKERS CUTTING APPLICATION ·GRADES is shown in order of: Finish|Light ·TECHNICAL DATA |Medium|Rough|Heavy. indicates reference pages, on the right hand page of each double-page spread. PHOTO OF INSERT INDICATION OF CHIPBREAKER APPLICABLE HOLDER PAGE indicates the designation indicates reference pages for details of applicable holders. for a chipbreaker. INSERT CORNER RADIUS (RE) a To Order : Please specify insert number and grade. A000