Общий каталог Mitsubishi 2020 - 2021 - страница 1175

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

INDEXABLE MILLING

Number of Teeth

LCCB

APMX

L8

CBDP

LF

LCCB

LCCB

L8APMXL8

CBDPCBDPAPMX

LFLF

ClassClass

HandHoning

Edge PreparationMC5020

MC5020MP6120

MP6120VP15TF

MP6130 MP7130MX3020

MP7140

MP9120

MP9130

VP15TF

VP20RT

MX3030

TF15

L

INDEXABLE MILLING

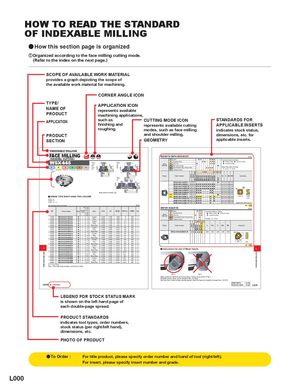

HOW TO READ THE STANDARD

OF INDEXABLE MILLING

aHow this section page is organized

zOrganized according to the face milling cutting mode.

(Refer to the index on the next page.)

SCOPE OF AVAILABLE WORK MATERIAL

provides a graph depicting the scope of

the available work material for machining.

CORNER ANGLE ICON

TYPE/NAME OFPRODUCT APPLICATION ICONrepresents availablemachining applications,

APPLICATION such as CUTTING MODE ICON STANDARDS FORfinishing andrepresents available cuttingAPPLICABLE INSERTS

roughing. modes, such as face milling indicates stock status,

PRODUCT and shoulder milling. dimensions, etc. for

SECTION GEOMETRY applicable inserts.

INDEXABLE MILLING

FACE MILLING 45°KAPR INSERTS WITH BREAKER (inch)