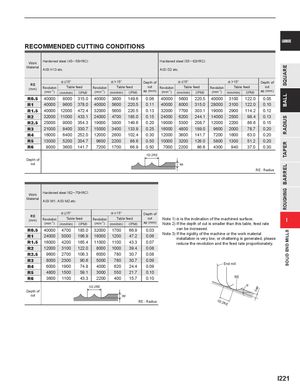

15°RevolutionTable feed(min-1)(mm/min)(IPM)Depth of% ≤15°cutRevolutionTable feedap (mm)(min-1)(mm/min)(IPM)% >15°RevolutionTable feed(min-1)(mm/min)(IPM)Depth ofcutap (mm)

R0.5 40000 8000 315.0 40000 3800 149.6 0.06 40000 5600 220.5 40000 3100 122.0 0.05

R1 40000 9600 378.0 40000 5600 220.5 0.11 40000 8000 315.0 28000 3100 122.0 0.10

R1.5 40000 12000 472.4 32000 5600 220.5 0.13 32000 7700 303.1 19000 2900 114.2 0.12

R2 32000 11000 433.1 24000 4700 185.0 0.15 24000 6200 244.1 14000 2500 98.4 0.13

R2.5 25000 9000 354.3 19000 3800 149.6 0.20 19000 5300 208.7 12000 2200 86.6 0.15

R3 21000 8400 330.7 15000 3400 133.9 0.25 16000 4800 189.0 9600 2000 78.7 0.20

R4 16000 6400 252.0 12000 2600 102.4 0.30 12000 3600 141.7 7200 1600 63.0 0.20

R5 13000 5200 204.7 9600 2200 86.6 0.50 10000 3200 126.0 5800 1300 51.2 0.20

R6 9000 3600 141.7 7200 1700 66.9 0.50 7000 2200 86.6 4300 940 37.0 0.30

<0.2RE

Depth of

cut ap

RE : Radius

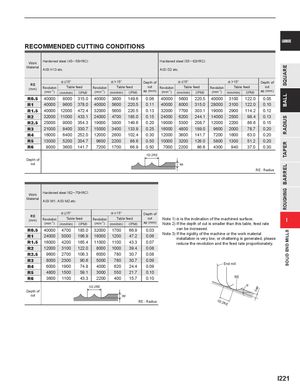

Work Hardened steel (62─ 70HRC)

Material AISI W1, AISI M2 etc.

RE(mm) % ≤15°RevolutionTable feed(min-1)(mm/min)(IPM)% >15°RevolutionTable feed(min-1)(mm/min)(IPM)Depth ofcutap (mm)Note 1) % is the inclination of the machined surface.Note 2) If the depth of cut is smaller than this table, feed rateI

R0.5 40000 4700 185.0 32000 1700 66.9 0.03 can be increased.

R1 24000 5000 196.9 16000 1200 47.2 0.06 Note 3) If the rigidity of the machine or the work materialinstallation is very low, or chattering is generated, please

R1.5 16000 4200 165.4 11000 1100 43.3 0.07 reduce the revolution and the feed rate proportionately.

R2 12000 3100 122.0 8000 1000 39.4 0.08

R2.5 9600 2700 106.3 6000 780 30.7 0.08

R3 8000 2300 90.6 5000 780 30.7 0.09

R4 6000 1900 74.8 4000 620 24.4 0.09 End mill

R5 4800 1500 59.1 3000 550 21.7 0.10

R6 3600 1100 43.3 2200 400 15.7 0.10 RE

<0.2RE %

Depth of

cut ap

RE : Radius <0.2RE

I221

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения