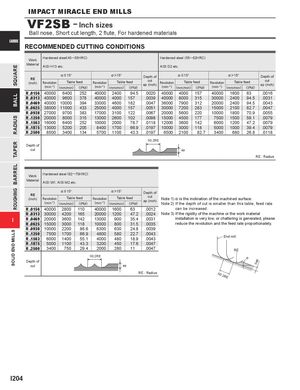

SQUAREBALLRADIUSTAPERBARRELROUGHINGSOLID END MILLS

15°RevolutionTable feed(min-1)(mm/min)(IPM)Depth of% < 15°cutap (inch)RevolutionTable feed(min-1)(mm/min)(IPM)% >15°RevolutionTable feed(min-1)(mm/min)(IPM)Depth ofcutap (inch)

R .0156 40000 6400 252 40000 2400 94.5 .0020 40000 4000 157 40000 1600 63 .0016

R .0313 40000 9600 378 40000 4000 157 .0039 40000 8000 315 30000 2400 94.5 .0031

R .0469 40000 10000 394 33000 4600 182 .0047 36000 7900 312 20000 2400 94.5 .0043

R .0625 38000 11000 433 25000 4000 157 .0051 30000 7200 283 15000 2100 82.7 .0047

R .0938 27000 9700 383 17000 3100 122 .0067 20000 5600 220 10000 1800 70.9 .0055

R .1250 20000 8000 315 13000 2600 102 .0098 15000 4500 177 7500 1500 59.1 .0079

R .1563 16000 6400 252 10000 2000 78.7 .0118 12000 3600 142 6000 1200 47.2 .0079

R .1875 13000 5200 205 8400 1700 66.9 .0197 10000 3000 118 5000 1000 39.4 .0079

R .2500 8500 3400 134 5700 1100 43.3 .0197 6500 2100 82.7 3400 680 26.8 .0118

<0.2RE

Depth of

cut ap

RE : Radius

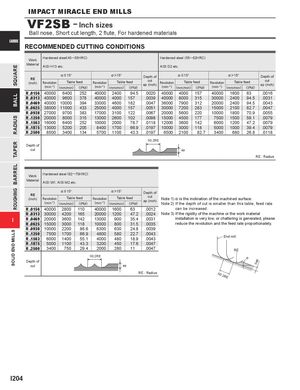

Work Hardened steel (62─ 70HRC)

Material AISI W1, AISI M2 etc.

RE(inch) % < 15°RevolutionTable feed(min-1)(mm/min)(IPM)% >15°RevolutionTable feed(min-1)(mm/min)(IPM)Depth ofcutap (inch)Note 1) % is the inclination of the machined surface.Note 2) If the depth of cut is smaller than this table, feed rate

R .0156 40000 2800 110 40000 1600 63 .0012 can be increased.

R .0313 30000 4200 165 20000 1200 47.2 .0024 Note 3) If the rigidity of the machine or the work material

I R .0469 20000 3600 142 13000 900 35.4 .0031R .06251500030001181000080031.5.0035installation is very low, or chattering is generated, pleasereduce the revolution and the feed rate proportionately.

R .0938 10000 2200 86.6 6300 630 24.8 .0039

R .1250 7500 1700 66.9 4800 580 22.7 .0043R .15636000140055.1400048018.9.0043 End mill

R .1875 5000 1100 43.3 3200 450 17.6 .0047

R .2500 3400 750 29.4 2000 280 11 .0047 RE

<0.2RE %

Depth of

cut ap

RE : Radius <0.2RE

I204

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения