Общий каталог Mitsubishi 2020 - 2021 - страница 961

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

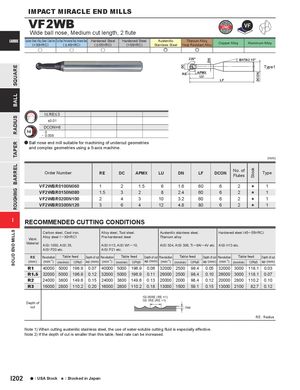

SQUAREBALLRADIUSTAPERBARRELROUGHINGSOLID END MILLS

DC

DN

Stock

DCON

IMPACT MIRACLE END MILLS

VF2WB

Wide ball nose, Medium cut length, 2 flute

CARBIDE Carbon Steel, Alloy Steel, Cast Iron Tool Steel, Pre-Hardened Steel, Hardened Steel Hardened Steel(<30HRC)( < 45HRC)( < 55HRC)Hardened Steel(>55HRC)AusteniticTitanium Alloy,Stainless SteelHeat Resistant AlloyCopper AlloyAluminum Alloy

u u u e e

220° BHTA2 15°

Type1

RE APMXLU

LF

I< RE< 3

±0.01

DCON=6

0

- 0.008

a Ball nose end mill suitable for machining of undercut geometries

and complex geometries using a 5-axis machine.

(mm)

Order Number RE DC APMX LU DN LF DCON No. ofFlutes Type

VF2WBR0100N060 1 2 1.5 6 1.6 60 6 2 s 1

VF2WBR0150N080 1.5 3 2 8 2.4 60 6 2 s 1

VF2WBR0200N100 2 4 3 10 3.2 60 6 2 s 1

VF2WBR0300N120 3 6 4 12 4.8 80 6 2 s 1

I RECOMMENDED CUTTING CONDITIONS

Carbon steel, Cast iron, Alloy steel, Tool steel, Austenitic stainless steel, Hardened steel (45─55HRC)

Work Alloy steel ( ─ 30HRC) Pre-hardened steel Titanium alloy

Material AISI 1050, AISI 35, AISI H13, AISI W1─10, AISI 304, AISI 306, Ti ─6Al ─4V etc. AISI H13 etc.

AISI P20 etc. AISI P21 etc.

RE Revolution Table feed Depth of cut Revolution Table feed Depth of cut Revolution Table feed Depth of cut Revolution Table feed Depth of cut

(mm) (min-1) (mm/min) (IPM) ap (mm) (min-1) (mm/min) (IPM) ap (mm) (min-1) (mm/min) (IPM) ap (mm) (min-1) (mm/min) (IPM) ap (mm)

R1 40000 5000 196.9 0.07 40000 5000 196.9 0.06 32000 2500 98.4 0.05 32000 3000 118.1 0.03

R1.5 32000 5000 196.9 0.12 32000 5000 196.9 0.11 26000 2500 98.4 0.10 26000 3000 118.1 0.07

R2 24000 3800 149.6 0.15 24000 3800 149.6 0.13 20000 2000 98.4 0.12 20000 2800 110.2 0.10

R3 16000 2800 110.2 0.20 16000 2800 110.2 0.18 13000 1500 59.1 0.15 13000 2100 82.7 0.12

<0.05RE (RE =1)

Depth of <0.1RE (RE >1)

cut