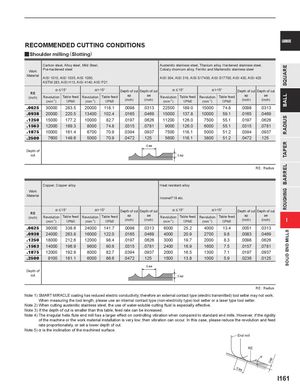

15° Depth of cut Depth of cut % < 15° %>15° Depth of cut Depth of cutRevolutionTable feedRevolutionTable feedapaeRevolutionTable feedRevolutionTable feedapae(min-1)(IPM)(min-1)(IPM)(inch)(inch)(min-1)(IPM)(min-1)(IPM)(inch)(inch)

.0625 30000 283.5 20000 118.1 .0098 .0313 22500 189.0 15000 74.8 .0098 .0313

.0938 20000 220.5 13400 102.4 .0165 .0469 15000 137.8 10000 59.1 .0165 .0469

.1250 15000 177.2 10000 82.7 .0197 .0626 11200 126.0 7500 55.1 .0197 .0626

.1563 12000 169.3 8000 74.8 .0315 .0781 9000 126.0 6000 55.1 .0315 .0781

.1875 10000 161.4 6700 70.9 .0394 .0937 7500 118.1 5000 51.2 .0394 .0937

.2500 7600 149.6 5000 70.9 .0472 .125 5600 118.1 3800 51.2 .0472 .125

< ae

Depth of

cut < ap

RE : Radius

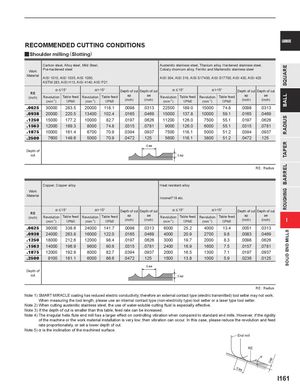

Copper, Copper alloy Heat resistant alloy

Work

Material Inconel718 etc.

RE(inch) % < 15° %>15° Depth of cut Depth of cut % < 15° %>15° Depth of cut Depth of cutRevolutionTable feedRevolutionTable feedapaeRevolutionTable feedRevolutionTable feedapae(min-1)(IPM)(min-1)(IPM)(inch)(inch)(min-1)(IPM)(min-1)(IPM)(inch)(inch)I

.0625 36000 338.6 24000 141.7 .0098 .0313 6000 25.2 4000 13.4 .0051 .0313

.0938 24000 263.8 16000 122.0 .0165 .0469 4000 20.9 2700 9.8 .0083 .0469

.1250 18000 212.6 12000 98.4 .0197 .0626 3000 19.7 2000 8.3 .0098 .0626

.1563 14000 196.9 9600 90.6 .0315 .0781 2400 16.9 1600 7.5 .0157 .0781

.1875 12000 192.9 8000 82.7 .0394 .0937 2000 16.5 1300 7.1 .0197 .0937

.2500 9100 181.1 6000 86.6 .0472 .125 1500 13.8 1000 5.9 .0236 .0125

< ae

Depth of

cut < ap

RE : Radius

Note 1) SMART MIRACLE coating has reduced electric conductivity; therefore an external contact type (electric transmitted) tool setter may not work.

When measuring the tool length, please use an internal contact type (non-electricity type) tool setter or a laser type tool setter.

Note 2) When cutting austenitic stainless steel, the use of water-soluble cutting fluid is especially effective.

Note 3) If the depth of cut is smaller than this table, feed rate can be increased.

Note 4) The irregular helix flute end mill has a larger effect on controlling vibration when compared to standard end mills. However, if the rigidity

of the machine or the work material installation is very low, then vibration can occur. In this case, please reduce the revolution and feed

rate proportionately, or set a lower depth of cut.

Note 5) % is the inclination of the machined surface.

End mill

RE

%

< ae

I161

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения