Общий каталог Mitsubishi 2020 - 2021 - страница 1629

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

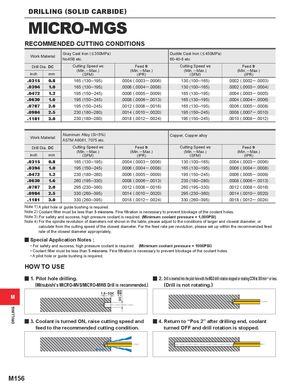

DRILLING (SOLID CARBIDE) MICRO-MGS RECOMMENDED CUTTING CONDITIONS Work Material Gray Cast Iron ( < 350MPa)No45B etc. Ductile Cast Iron ( < 450MPa)60-40-8 etc. Drill Dia. DC Cutting Speed vc Feed fr Cutting Speed vc Feed fr (Min. ─ Max.) (Min. ─ Max.) (Min. ─ Max.) (Min. ─ Max.) inch mm (SFM) (IPR) (SFM) (IPR) .0315 0.8 165 (130─195) .0004 (.0003 ─ .0006) 130 (100─165) .0002 (.0002 ─ .0003) .0394 1.0 165 (130─195) .0006 (.0004 ─ .0008) 130 (100─165) .0002 (.0003 ─ .0004) .0472 1.2 195 (150─245) .0006 (.0005 ─ .0009) 165 (130─195) .0004 (.0003 ─ .0005) .0630 1.6 195 (150─245) .0008 (.0006 ─ .0013) 165 (130─195) .0004 (.0004 ─ .0006) .0787 2.0 195 (150─245) .0012 (.0008 ─ .0016) 165 (130─195) .0006 (.0005 ─ .0008) .0984 2.5 230 (180─280) .0014 (.0010 ─ .0020) 195 (150─245) .0008 (.0007 ─ .0010) .1181 3.0 230 (180─280) .0018 (.0012 ─ .0024) 195 (150─245) .0010 (.0008 ─ .0012) Work Material Aluminum Alloy (Si<5%)ASTM A6061, 7075 etc. Copper, Copper alloy Drill Dia. DC Cutting Speed vc Feed fr Cutting Speed vc Feed fr (Min. ─ Max.) (Min. ─ Max.) (Min. ─ Max.) (Min. ─ Max.) inch mm (SFM) (IPR) (SFM) (IPR) .0315 0.8 165 (130─195) .0004 (.0003 ─ .0006) 130 (100─165) .0004 (.0003 ─ .0006) .0394 1.0 195 (150─245) .0006 (.0004 ─ .0008) 165 (130─195) .0006 (.0004 ─ .0008) .0472 1.2 230 (180─280) .0006 (.0005 ─ .0009) 195 (150─245) .0006 (.0005 ─ .0009) .0630 1.6 260 (195─330) .0008 (.0006 ─ .0013) 230 (180─280) .0008 (.0006 ─ .0013) .0787 2.0 295 (230─360) .0012 (.0008 ─ .0016) 260 (195─330) .0012 (.0008 ─ .0016) .0984 2.5 330 (260─395) .0014 (.0010 ─ .0020) 295 (230─360) .0014 (.0010 ─ .0020) .1181 3.0 330 (260─395) .0018 (.0012 ─ .0024) 330 (260─395) .0018 (.0012 ─ .0024) Note 1) A pilot hole or guide bushing is required. Note 2) Coolant filter must be less than 5 microns. Fine filtration is necessary to prevent blockage of the coolant holes. Note 3) For safety and success, high pressure coolant is required. (Minimum coolant pressure = 1,000PSI) Note 4) For the spindle revolution of diameters not shown in the table, please adjust to the conditions of larger and closest diameter, or calculate from the cutting speed of the closest diameter. For the feed rate per revolution, please set up within the recommended feed rate of the closest diameter appropriately. y Special Application Notes : • For safety and success, high pressure coolant is required. (Minimum coolant pressure = 1000PSI) • Coolant filter must be less than 5 microns. Fine filtration is necessary to prevent blockage of the coolant holes. • A pilot hole or guide bushing is required. HOW TO USE y 1. Pilot hole drilling. y 2. Drill is inserted into the pilot hole with the MGS drill rotation stopped or rotating CCW at 300 min-1 or less. (Mitsubishi’s MICRO-MVS/MICRO-MWS Drill is recommended.) (Drill is not rotating.) DC M y 3. Coolant is turned ON, raise cutting speed and y 4. Return to “Pos 2” after drilling end, coolant feed to the recommended cutting condition. turned OFF and drill rotation is stopped. M156 DRILLING DC