Общий каталог Mitsubishi 2020 - 2021 - страница 1630

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

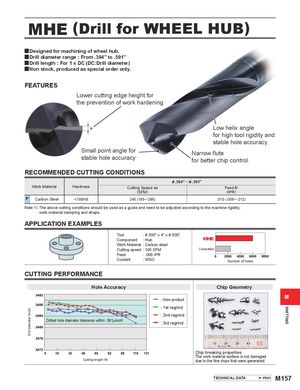

MHE (Drill for WHEEL HUB) y Designed for machining of wheel hub. y Drill diameter range : From .394" to .591" y Drill length : For 1 x DC (DC:Drill diameter) y Non stock, produced as special order only. FEATURES Lower cutting edge height for the prevention of work hardening H Low helix angle for high tool rigidity and stable hole accuracy. Small point angle forstable hole accuracy Narrow flutefor better chip control. RECOMMENDED CUTTING CONDITIONS & .394" – & .591" Work Material Hardness Cutting Speed vc Feed fr (SFM) (IPR) P Carbon Steel <180HB 245 (195 ─ 295) .010 (.006─.012) Note 1) The above cutting conditions should be used as a guide and need to be adjusted according to the machine rigidity, work material clamping and shape. APPLICATION EXAMPLES Tool : &.500" x 4" x &.500" Component : Hub MHE Work Material : Carbon steel Cutting speed : 195 SFM Competitor Feed : .006 IPR Coolant : WSO Number of holes CUTTING PERFORMANCE Hole Accuracy Chip Geometry : New product M : 1st regrind : 2nd regrind Drilled hole diameter tolerance within .591!inch! : 3rd regrind Chip breaking properties The work material surface is not damaged Cutting length (ft) due to the fine chips that were generated. TECHNICAL DATA P001 M157 Drill diameter (inch) DRILLING